What is a Steam Shrink Tunnel Machine?

A steam shrink tunnel machine is a type of heat tunnel machine that shrinks wrap film (like PETG) or sleeves snugly and uniformly onto products like bottles using steam heat.

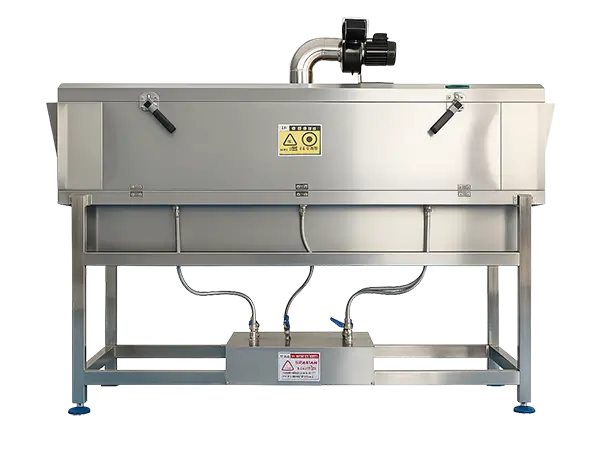

It generally consists of a stainless-steel frame and a steam generator. Conveyor System, temperature, Steam Control System, Condensate Drainage System.

In comparison to other shrinking heat tunnels, this is the most efficient and ideal heat tunnel for sleeve shrink labeling large quantities of bottles.

Tengyi has been manufacturing steam shrink tunnels since 2014 and has accumulated tons of experience in shrink tunnel design and manufacturing.

Main Features of the TY-W300 Steam Shrink Tunnel

Tunnel Length: The 1.3-meter internal tunnel length of the TY-M300 can be customized to accommodate the desired heat shrink rate of your product.

Entry/Exit Dimensions: The TY-W300 has an entry/exit width and height of 200x200mm, which means the products processed must be within the limits of these dimensions. Products exceeding this range would need specific adjustment and tunnel lengthening.

Stainless-steel body: #304 Stainless steel body is rust-resistant and durable, making it ideal for long-term use and easy cleaning.

Production Speed: Up to 150 bottles per minute for high-speed, fully automatic production.

Key Advantages of the TY-W300 Steam Shrink Tunnel

Superior Shrinking Performance

- 360-Degree Uniform Heating:Ensures that the label adheres perfectly to the bottle-shaped products

- Distortion-Free Graphics: Guarantees visually appealing packaging without wrinkles or bubbles

- Versatile for Unique Product Forms: Provides a flawless finish for items other than standard bottles.

Achieve Shrink Label Perfection at Lower Temperatures

Our TY-W300 performs heat and shrink labels at a significantly lower temperature of just 100°C(212°F). This makes it a medium-to-low temperature system compared to electric heating tubes like TY-5030 or TY-5545 that operate at 130-180°C (266-356°F).

This approach offers:

Gentle Heating: Prevents product deformation and damage.

Energy-Saving & Eco-Friendly: Results in lower long-term operating costs and a reduced environmental footprint.

Strong adaptability

- Multi-Product Compatibility: Works for liquid and solid products such as juice and soft drinks, and can even be used for canned foods.

- Special Material Handling: Best for PETG labels, which give you strength and stretch to fit product shapes.

- Tamper-Evident Packaging: Using a steam shrink tunnel with a shrink label wrapper like the TY-P150 creates the maximum security seal. Any evidence of tampering will become apparent immediately, satisfying compliance regulations and consumer confidence.

Customization options for the TY-W300 Steam Shrink Tunnel

- Adjustable steam nozzles and baffles for varied bottle shapes.

- Digital steam flow & temperature control for energy efficiency

- We offer the flexibility of either a built-in or separate steam generator, adjustable to meet specific customer needs.

- A condensate collection system is included to prevent corrosion and maintain hygiene.

Get Your Shrink Sleeve Steam Tunnel Solution Today!

Contact us for detailed quotes, live demos, and expert consultation

Wide-Ranging Industry Applications

Beverage Industry

Together with the Shrink label machine, it’s Ideal for bottled water, juices, sodas, beer, and spirits with waterproof and fade-resistant labels.

Cosmetics & Personal Care

Handles uniquely shaped bottles and premium packaging, enhancing shelf attractiveness.

Food & Other Industries

Offer tight, uniform, tamper-evident shrink sleeve labeling/sealing around bottles, cans, or containers.

Add a visible security/seal band for food safety and/or chemical hazard protection (tamper-evident function).

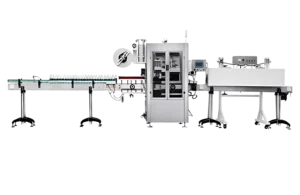

Heat Shrink Tunnel for Irregular shaped Bottles: TY-W300 Steam Tunnel + P-150 Labeling Machine in beverage Industry Application

Why Choose Tengyi Shrink Sleeve Steam Tunnels?

Our team has been custom-making high-quality steam shrink tunnels and complete solutions for a range of industries since 2014. Our customers often mention that they find our machines sturdy, durable, and intelligent.

Hassle-Free After-Sale Service

Repair/Modification Plan Assistance

A Repair/Modification Plan for the shrink sleeve steam tunnel will be provided to help support you with repairs.

If you carry out repairs on-site overseas and this involves the support of engineers from Tengyi, you will pay for the visa, airfare, hotel accommodation, and labor costs.

Technical Training

Video materials will be supplied for training of the shrink sleeve steam tunnel (for use in installation, debugging, etc).

If you would like to have training on-site overseas, you will pay for the visa, airfare, hotel accommodation, and labor costs for the Tengyi engineers.

Remote diagnosis and troubleshooting

We will provide a video explanation, etc., to help support the customer in getting used to the shrink sleeve steam tunnels or to help solve problems you are having using the tengyi machine

Our ultimate goal is to ensure the shrink sleeve steam tunnel is stable and durable, which helps your business.

FAQs Regarding TengyiSteam Shrink Tunnels

What is the price range for a steam shrink tunnel machine?

Prices vary significantly based on configuration. TY-W300 steam heater with tunnel size 1300x200x200mm and integrated steam generator, the shrink tunnel for sale is priced at USD 4500 ex-works.

How does a steam shrink tunnel machine work?

A steam shrink tunnel machine uses steam as a heat transfer medium to transfer heat to items in a tunnel. Steam within the tunnel surrounds the items and maintains a high level of heat to shrink the sleeves(like PETG, PVC etc). The inside of the tunnel has manifolds and valves installed to regulate how much steam is directed in specific directions while maintaining a high flow to support the shrink-down process.

How hot do steam tunnels get?

Since steam’s maximum temperature is 100°C (212°F), steam heat tunnels typically reach that temperature. Heat loss usually puts the effective operating range between 93°C and 100°C (199°F to 212°F).

Per Tengyi team’s experience, in some steam tunnels with steel conveyor belts, the belt can become even hotter due to continuous steam exposure. As a result, the bottom part of bottles—where the PETG film touches the steel belt—may shrink faster than the top, which doesn’t have direct contact with the belt.

Does a steam shrink tunnel machine require an additional steam boiler?

Not necessarily. Whether or not an additional steam generator is needed depends on the customer’s actual requirements. The TY-W300 includes a built-in steam generator, which saves money on installing a separate steam generator.

Can I test my product's effect before purchasing?

Yes, our factory can provide free shrink sleeve testing for your products and will provide a video of your product running after the test is completed, so you can witness the results firsthand.

What is the production lead time after purchase?

Steam heat tunnel production usually takes up to 30 working days, depending on the job quantity and complexity.

What after-sales support and warranty services does your company provide?

For overseas customers, we typically offer lifetime phone and video support, as well as cost-priced support for spare parts and consumables. For any other support, contact our sales and technical team for a comprehensive after-sales service plan

What are the core advantages of a steam shrink tunnel machine?

Compared to hot air shrink tunnels, steam shrink tunnels provide superior shrink quality — uniform, wrinkle-free, and bubble-free results.

They offer high-speed shrink wrapping of up to 150–200 pieces per minute, making them faster than most hot air tunnels and ideal for large-scale production, such as bottled water packaging.

Which industries and products are suitable for steam shrink tunnel machines?

Steam shrink tunnel machines are ideal for industries and products that are not moisture-sensitive and require high-quality, fast shrink labeling. Common applications include:

Beverage industry – bottled water, juices, alcoholic drinks

Cosmetics and personal care – lotions, shampoos, and uniquely shaped bottles

Industrial and household products, including various chemicals

How do steam, hot air, and radiant heat shrink tunnels compare?

Steam Tunnel: These shrink tunnels provide the most uniform, high-quality shrink. Most suited to odd-shaped products with high graphic integrity. Cons: includes must consider moisture issues, and needs daily maintenance like drainage.

How does a steam shrink tunnel machine make the labels free of wrinkles or bubbles?

A steam shrink tunnel machine makes a label free of wrinkles or bubbles because it has a great capacity to heat uniformly. As opposed to dry heat, the moist heat that steam generates will penetrate and surround the shrink film quickly to allow for more uniform shrinkage, which allows better clarity of graphics and vivid colors.

What types of shrink film materials can a steam shrink tunnel machine handle?

PVC, PETG (Polyethylene Terephthalate Glycol), OPS (Oriented Polystyrene), and PLA (Polylactic Acid).

What adjustable options are available in shrink tunnels with steam?

Steam shrink tunnel machines often provide various adjustable options to accommodate varying shrink requirements and types of products. Adjustable steam nozzles or deflectors, electronic steam control with digital settings, and varying exhaust speeds are among the more common options.

Are steam shrink tunnel machines appropriate for refrigerated or pre-filled products?

Yes. Steam shrink tunnels operate at relatively low temperatures (180-200 degrees) and allow products to pass through at a higher rate. Since steam shrink tunnels operate at low temperatures, they are also suitable for packaging pre-filled or refrigerated items. Steam tunnels seal products faster than hot air heat tunnels while minimizing container deformation.

Why are shrink sleeves more popular than traditional pressure-sensitive labels?

Shrink sleeves are popular because they offer more label space, act as tamper-evident seals, and are more durable than pressure-sensitive labels.