shrink wrapping machine for cosmetic products

Shrink Wrap Machines for Cosmetic Products

Why Use a Shrink Wrap Machine for Cosmetic Products?

Tamper evidence and Security

One of the biggest selling points is tamper evidence. Customers want assurance that their cosmetic products haven’t been opened or altered. A shrink wrap seal makes tampering obvious, giving customers peace of mind

Enhance product presentation

Protection from external elements

Space and cost efficiency

Advanced Shrink Wrapping Solutions for the Cosmetics and Personal Care Industry

Whether you need tamper-evidence, full-body decoration, or sleek box wrapping, we have a solution to meet your output needs.

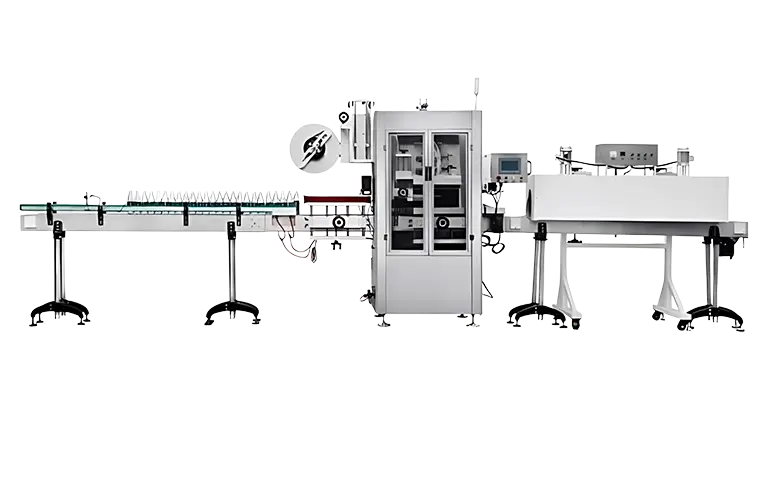

1. High-Visual-Impact Bottle Decoration and Tamper-Evidence

Perfect for bottles, jars, and other shaped containers like body wash, shampoo, creams, and serums.

For most cosmetic and daily chemical bottles, the TY-P150 Sleeve Labelling Machine is the ideal choice. It protects your product and attracts more customers.

Key Applications & Benefits

Full-Body Design: Wraps your bottles with 360-degree graphics and branding for maximum shelf appeal.

Tamper-Evident Seal: Secures the cap or whole product to ensure customer confidence.

Custom Fit: Adapts perfectly to the unique shapes of your bottles and jars.

Production Speed

The normal passing rate ranges from 60 to 120 pieces per minute, depending on the package size.

For the smallest items, such as lipstick bottles, our sleeve labeling machines can process up to 120 pieces per minute.

Case Study: The Shrink Sleeve Labeling System (Machine + Steam Heat Tunnel) Achieves Approx. 120 Bottles Per Minute

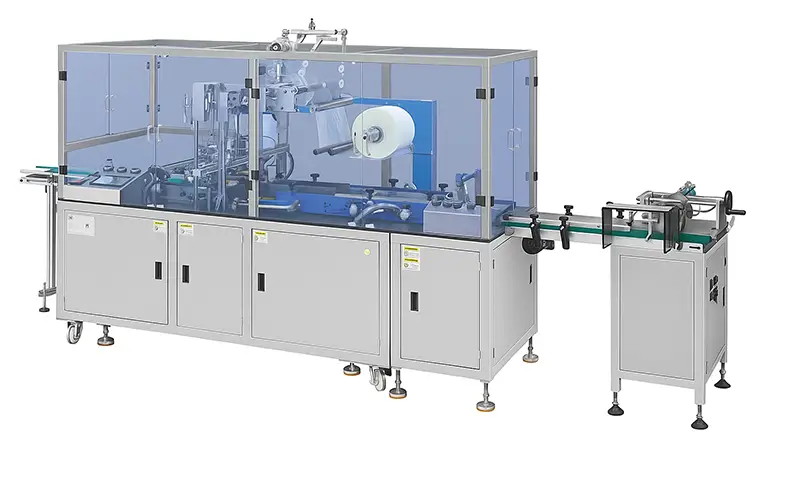

2. Premium Film Overwrapping For Boxed Cosmetic Products

Ideal for: Boxed cosmetics, perfumes, delicate makeup sets, and high-value single items.

When packaging your boxed cosmetic products, our 3D Overwrapping Machine provides a high-end finish that screams quality and acts as a primary layer of protection.

With this machine, a precise, heat-sealed film is applied, producing a crisp, professional, tamper-evident seal that keeps boxes in perfect condition.

3.Horizontal Flow Shrink Wrapping Machine for Cosmetics & Daily Care Products.

If you frequently produce large quantities of cosmetic and daily care products in a consistent size

(length 80mm to 300mm, width plus height 35mm to 240mm, height 50mm to 100mm)

and need fast packaging, the Tengyi Horizontal Flow Wrapper with Shrink Tunnel is an excellent choice.

Crystal-clear, Smooth Finish

Uses POF shrink film to provide a tight, flawless wrap, suitable for premium skincare and cosmetics.

Fast and efficient.

Wrap 30 to 120 packs per minute, offering reliable throughput to support growing beauty brands.

Versatile packaging options.

Suitable for single bottles like toners or oils as well as gift sets and twin packs—each wrapped to perfection.

Cost-effective and sustainable

Cuts film waste by up to 25% compared to traditional L-bar sealers, reducing material costs

Consistent, reliable operation

It features PLC smart controls and a three-servo system, ensuring stable and high-quality wrapping even during

extended production runs and with various types of products.

4.Affordable and Versatile Starter Solution for Cosmetic Products—L-Bar Sealers.

Key Advantages:

✨ Flawless presentation

⚙️ Consistent automated sealing

💅 Handles Any Product Shape

Ready to Select the Right Machine for Your Cosmetic Line?

Talk to our experts today and find the right shrink wrap machine for your line.

Why Choose Tengyi as Your Shrink Wrap Machine Supplier for Cosmetic and Daily Care Products?

With 10+ years of experience in the cosmetic and daily care product industries, we provide carefully customized shrink wrap machine solutions to support your cosmetic business.

Hassle-Free After-Sale Service

Supply of Spare Parts.

Tengyi offers shrink wrap machine spare parts, such as sealing blades and silicone pads, at a cost price.

Repair/Modification Plan Assistance

A Repair/Modification Plan for the shrink wrap machine will be provided to help support you with repairs.

If you carry out repairs on-site overseas and this involves the support of engineers from Tengyi, you will pay for the visa, airfare, hotel accommodation, and labor costs.

Technical Training

Video materials will be supplied for training (for use in installation, debugging, etc).

If you would like to have training on-site overseas, you will pay for the visa, airfare, hotel accommodation, and labor costs for the Tengyi engineers.

Remote diagnosis and troubleshooting

We will provide a video tutorial and other support to help customers get familiar with Tengyi shrink wrap machines and solve any issues when wrapping your cosmetic or daily care products.

Shrink Wrap Machine: Key Applications in Cosmetic & Daily Consumer Goods Packaging

Multi-Item Combination Packaging

- Multi-Bottle/Unit Bundling: Examples include bundled sets of shampoo, conditioner, and body wash. Tightly wrapping your cosmetics or daily care packages with shrink film turns them into a single, strong unit. This makes them much easier to ship and instantly boosts their appeal when displayed in stores.

- Promotional Kits/Gift Sets: Used for personal care, skincare, or cosmetic combination sets.The shrink bundling machines can quickly wrap the products to form one cohesive set. You get stronger packaging and a tamper-evident seal that gives customers peace of mind.

Bottle Neck and Cap Sealing

- Pump/Screw-Cap Bottle Sealing:

- Aerosol/Spray Cap Sealing:

Outer Protective Film for High-End Gift Boxes:

Case Study

Cosmetics: 4 Years of Partnership

Premium Packaging for a Top Global Brand

Result: Zero Fish-Eyes & Crystal Clear Presentation. Learn More

Cosmetic: Eliminating the Labor Bottleneck

From Manual Labor to 100 BPM Automated Precision.

Result: 100% Speed Jump & 3 High-Cost Laborers Removed. learn more

For more details on our shrink wrap machine and their industry solutions,

Please visit the industrial shrink wrap equipment page