You probably know how it goes—manual case sealing can really slow things down.

Keeping every box sealed neatly and consistently is tougher than it sounds.

That’s where case sealers make a real difference.

But choosing between a semi-automatic and a fully automatic case sealer isn’t always simple.

Each has its strengths—and the right fit depends on how your line actually runs.

Think about your daily output, your budget, and how your packaging flow is organized.

Those three factors usually tell you what kind of case sealers make sense for your operation

What Is a Case Sealer?

A case sealer is a kind pacakge machine which applies tape or adhesive to close and seal cartons or boxes. Instead of depending on manual work, it keeps the sealing process steady, fast, and consistent every time.

That means fewer tape issues, and a more professional look on every box leaving your line.

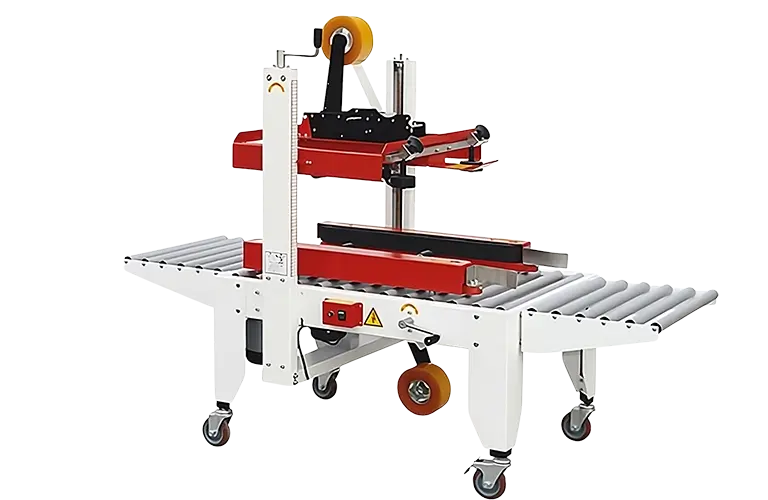

With a semi-automatic case sealer, your operator folds the flaps and feeds the box in.

From there, the sealer automatically tapes both the top and bottom of a carton.

It’s simple, dependable, and fits perfectly into small to mid-sized packaging operations.

Key Features:

- Manual feeding by the operator

- Automatic carton top and bottom sealing

- Adjustable width and height for different carton sizes

Best For:

- Growing manufacturing plants

- E-commerce and logistics centers

- Small-scale producers sealing 300–800 cartons per hour

Advantages:

✅ Low upfront cost

✅ Easy to use and maintain

✅ Handles a variety of box sizes

Disadvantages:

❌ Requires manual flap folding and carton feeding

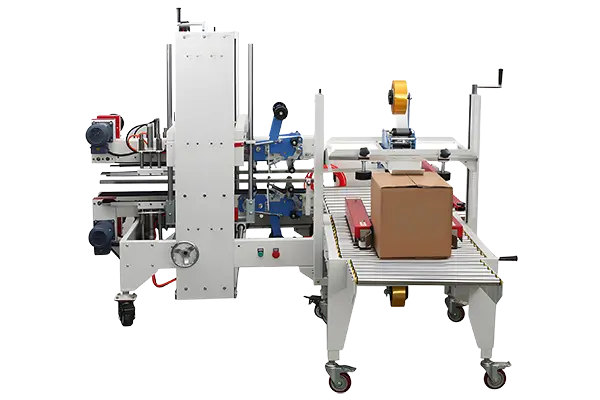

A fully automatic case sealer takes care of everything—folding the flaps, feeding and centering the cartons, and sealing them—all without an operator.

It connects smoothly with automated conveyor lines, creating a nonstop flow from case forming to sealing.

As boxes move through, the sensors detect, adjust, and seal each one on the fly. No downtime. No manual handling.

Key Features:

- Automatic flap folding and sealing

- Smart sensors for detection and positioning

- Built for 24/7 operation

- Integrates easily with case erectors or palletizers

Best For:

- Continous package lines, eg. food and beverage facilities with nonstop packaging needs

- Large 3PL and distribution centers

Advantages:

✅ Consistent sealing at higher speeds

✅ Reduces labor fatigue

✅ Fully compatible with large-scale automation setups

Disadvantages:

❌ A bit Higher initial investment than semi-automatic sealer

How Fully Automatic Case Sealers Work

Semi-Automatic vs. Fully Automatic: Key Differences

| Feature | Semi-Automatic (S/A) | Fully Automatic (F/A) |

| Labor Requirement | Requires an operator for feeding | Requires zero operator intervention |

| Speed (Throughput) | Limited by operator speed (e.g., 10–20 CPM) | Reduced speed (e.g., 8–10 CPM) Due to an additional action performed by this machine to fold the top and bottom flaps of the carton. |

| Flap Folding | Manual folding required | Automatic folding integrated |

| Initial Cost | USD700-980 | USD1687-2108 |

| Integration | Standalone or partial line setup | Fully integrated conveyor system |

| Ideal User | Small-to-Midsize Enterprises (SMEs) | Large-scale production facilities |

How to Choose the Right Case Sealer

1. Production Volume

A semi-automatic case sealer like TY-YZ500 usually makes sense if you seal fewer than 1,000 cartons a day. By the time you pass that point, the automatic carton sealer like TY-ZG500 pays for itself in labor and time savings.

2. Budget and ROI

Semi-automatic case sealers are budget-friendly, like Exworks USD700, and quick to install. Fully automatic ones cost twice more but deliver strong returns once you factor in labor reduction and long-term output.

3. Carton Variety

If your packaging line handles multiple carton sizes, look into a random case sealer like TY-R600

These automatically adjust to the height and width of each box—available in both semi and fully automatic models.

4. Package Line Integration

Already using conveyors or case erectors?

Then a fully automatic sealer will likely fit better and keep your line running continuously.

Real Example: Step-by-Step Growth

A snack manufacturer in Guangzhou used to manually seal 500 cartons per hour before 2021

After switching to a semi-automatic sealer, they cut their labor in half.

Six months later, as production climbed to 1,500 cartons per hour, they upgraded again—this time to a fully automatic model TY-ZG500

That move saved two more workers and lifted output by 40%.

It’s a good reminder that automation often grows along with your business.

Cost Overview (Typical Range)

| Machine Type | Approx. Price (Ex works) | Production Rate |

| Semi-Automatic Case Sealer | USD750-800 | 10-20pcs |

| Automatic Case Sealer | USD1700-2100 | 8-10pcs |

Note: Actual pricing depends on model, speed, and customization.

Which machine should you choose?

Start with a semi-automatic sealer if your team is small or if you’re just getting started. It’s affordable, steady, and easy to maintain.

If your line runs non-stop and labor costs climb, a fully automatic case sealer is a smart long-term investment. And you’ll free up manpower and gain consistent throughput every shift.

Check out our full range of case sealers and find the perfect one for your industry.

Need Guidance?

With more than 10 years experience in the case sealer manufacturing, we can help manufacturers choose the right sealing machine for their production setup. Whether you’re sealing 100 boxes or 10,000 a day, we’ll find the balance that fits.

Talk to our team today, and let’s plan the next step for your packaging line.