What Is a Steam Heat Tunnel?

A steam heat tunnel is a critical component in modern packaging lines, engineered to deliver precision shrinking for film or sleeve labels. Utilizing low-pressure saturated steam, it ensures rapid and uniform heat distribution around the product.

Compared to traditional hot air tunnels, steam technology offers significantly faster heat transfer and superior conformity to complex container geometries. This makes it the ideal choice for contoured bottles, uniquely shaped containers, and high-speed production environments.

Widely adopted across the beverage, food, and personal care sectors, steam shrink tunnels are the industry standard for full-body shrink sleeves and tamper-evident seals. They guarantee a flawless, wrinkle-free finish, ensuring consistent, professional coverage across the entire product surface.

Why Choose Steam? The Science of Perfect Shrinking

Technical Highlights & Core Advantages

The electric tunnels force the dry heat through certain fixed angles, creating unbalanced and uneven shrink rates. In contrast, Steam is capable of creating a continuous 360° thermal envelope, permitting all portions of the label to shrink equally. The outcome is a smooth, perfectly finished surface with no wrinkles, bubbles, or visual deforms, no matter what the shape of your container is.

Safe for Your Product (Low-Temp Processing)

Higher-temperature systems have the risk of damaging the bottles or their contents. TY-W300 controls 100°C (212°F) steam, which does not expose the tunnels to 180°C or higher. This is a mild thermal conduction which protects delicate PET films and temperature-sensitive liquids, allowing the shrinking of the film to be precise, while maintaining structure and great quality of the product.

Efficiency Meets Consistency

Steam conducts heat much more effectively than dry air, almost up to 20 times better. That efficiency enables greater throughput and shorter tunnels, maintaining the speed between 50 and 150 BPM. The damp, humid conditions guarantee high repeatability and reliability throughout the process.

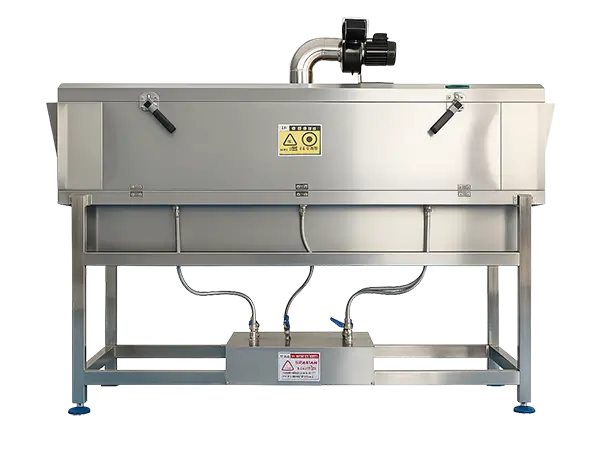

Main Features of the TY-W300 Steam Heat Tunnel

Precision Steam Distribution for Complex Shapes

Feature: 6 adjustable steam manifolds (304 stainless steel) with adjustable hole positioning.

Benefit: The six-zone system provides the operator with a full range of directional control and the steam can be directed where needed. Whether it is tapered necks or curved bottoms, you can adjust every area to be deformation-free.

Built to Last: Full Stainless Steel Construction

Feature: 304 stainless steel frame (40201.5mm) and 1.2mm-thick body panels.

Benefit: It is engineered to be used in wet and high-humidity conditions on a continuous basis. The heavy-grade 304 stainless steel is resistant to wear, corrosion, and rust, ensuring stability of the product over a long period and a professional look even after years of exposure to steam.

Stable & Smooth Conveying Feature:

Feature:POM Chain Plate Conveyor with 550W variable-speed motor (0–12m/min)

Benefit: The long-lasting POM chain provides smooth, low-friction motion that reduces the wobble of bottles. It has a broad speed range that will synchronize with the upstream filling or labeling lines, ensuring a smooth transition and reliable product handling.

Independent Steam Power (Separate Generator)

Feature: External Carbon Steel Boiler (ZQA.01) with High-Pressure Pump (1/4DWL-550).

Benefit: The physical separation between the generator and the tunnel protects the electronics against heat and moisture. The stainless steel heating tubes and industrial pump provide a consistent and stable stream of steam (maximum of 0.7MPa) that can supply the high-speed lines without pressure fluctuations.

Tunnel Dimensions

1.3 m length × 200 mm opening – both fully customizable

Speed Capacity

Up to 150 BPM (Adjustable 0–12m/min)

Material

Full #304 Stainless Steel (Rust-Proof)

Flexibility

Fits bottles up to 200mm height/width

Why Choose TY-W300: Higher Efficiency and Lower Heat Damage Risk

Precision at moderate Temperatures (100°C)

A steam tunnel provides a stable, mild 100°C steam environment compared to the hot-air tunnels, which reach extreme temperatures of 160°C-180°C or even higher.

This regulated temperature enables labels to fit specially to the shape of the bottle without exposing the product to heat that can be detrimental to the product. It is a safer and more dependable option for temperature-sensitive containers, allowing safe application without damaging or deforming the objects.

Universal Versatility: Perfect Compatibility with Multiple Containers

Our steam shrink system operates seamlessly within the operating dimensions of the tunnel to accommodate juices, water, dairy products, cans, as well as an extensive array of multi-shaped containers. The steam provides a 360-degree wrap around any profile and it can easily conform to regular and irregular shapes. It provides a clean, smooth, and accurate finish to a shrink-even to difficult shapes like tapered bodies, oval shapes or curved-bottom containers, and maintains a similar appearance to all SKUs.

Security & Immediate Compliance

Security is non-negotiable. To achieve the highest level of safety and reliability during operation, we have constructed our steam generator with two independent safety mechanisms:

Pressure Controller (Auto-Power Cut-off)

This is the first layer of protection in the system. Once the internal pressure goes above a preset warning level, the pressure controller automatically shuts the power down. The heating is gated, the generation of steam is discontinued, and the pressure is regulated at its origin and the unsafe accumulation is prevented before it can occur.

Mechanical Safety Valve (Overpressure Relief)

The safety valve, as the last mechanical protection, is triggered in case the internal pressure in the steam generator suddenly surpasses the standard pressure (e.g., 0.7\MPa). The excess steam is automatically released through the valve, which removes pressure and eliminates the dangers of excessive pressure.

Easy Maintenance: To ensure the proper functioning of the system, users would only need to check and change the safety valve within the recommended time, and its protective feature will still be effective in the long term.

Tailored to Your Production Line

Adaptable Steam Distribution

Adjust the positions and angles of steam manifolds to target the designated areas.

Whether it is a tapered neck or a complicated bottom, the system will allow you to balance the distribution to get perfect and uniform results.

Flexible Steam Source Configuration

Choose the steam configuration that is suitable for your plant. Our high-volume external steam generators are our specialty, although compact built-in designs can also be made where space is a factor.

Not Sure If Steam Is Right for Your Container?

Send us your sample bottles for a Free Shrink Test. We’ll record the process so you can see the results before you decide

No obligation. 100% Privacy Guaranteed

Proven Performance Across Industries

Beverage& Liquid Dairy

Challenge:Labels can slip on wet surfaces and in fast moving lines.

Solution: The TY-W300 steam easily permeates moisture and adheres waterproof PVC/PET labels on cold-filled bottles, securely and safely, without bubbles.

Perfect for: Soft drinks, Craft beer, Liquid dairy.

Cosmetics & Personal Care

Challenge: Non-uniform or curved shapes do not work well with dry-heat systems.

Solution: Our 360° steam environment fits perfectly with tapered, oval, or hourglass bottles, creating perfect premium packaging.

Perfect for: Shampoo, Lotions, Perfumes.

Food & Pharmaceuticals (Safety First)

Challenge: Visible tamper prevention is essential for consumer trust.

Solution: Design hard, tamper-evident sleeves and neck bands for sauces, dressings, and chemical products. Any form of interruption is immediately noticeable.

Perfect for: Sauces, Nutraceuticals, Cleaning chemicals.

Witness the Difference: Flawless Shrink Results in Real-Time

Watch immediately how the TY-W300 manages irregularly shaped bottles with zero distortion during high-speed production.

About this Demo: In this video, a full bottling line of the beverage is demonstrated with the use of the TY-W300 Steam Heat Tunnel. The system is designed to accommodate non-standard bottle profiles and offers high levels of tamper-evident sealing with PET shrink film. Perfect for juice, yogurt, and soft drink lines that require high-speed stability.

Why Work With Us?

Engineered for Longevity, Designed for Intelligence.

Ever since 2014, Tengyi has dedicated itself to a single task: to master steam shrink technology. We do not simply assemble machines, we create industrial-grade solutions that can be put to 24/7 working. This is why more than 500 plants around the world use our tunnels as essential packaging lines.

We Back What We Build: Lifetime Global Support

Remote Diagnostics and Video Support (Free Forever)

Real-time problem solving with video tutorials and live tech support. We have solved more than 90% of problems at zero cost.

Comprehensive Training Resources

Complete installation and debugging documentation for every machine will allow your team to be operational on day one.

On-Site Commissioning Available

Need hands-on help? Our senior engineers will come to your plant for installation and also provide training. (Service packages available upon request.)

Experience the Tengyi Difference.

We Solved the Common Headaches of Steam Tunnels

The Pressure Drop Problem

Challenge: The majority of tunnels experience irregular steam pressure, which results in the shrinking of gaps during rush hours.

TY-W300 Solution: Our high-performance external generator is capable of providing a constant production of 20-30 kW of power and maintains an output of 0.4 Mpa constant pressure at full speed.

The Water & Corrosion Issue

Challenge: Steam generators can suffer corrosion due to the accumulation of scale and oxidation, which decreases the heating efficiency and decreases the total lifespan of the equipment.

TY-W300 Solution:

- Soft Water Usage: We suggest the use of purified soft water so as to reduce the formation of scales at the origin and ensure that the system is running at its optimal capacity.

- Corrosion-Resistant Design: TY-W300 is constructed using stainless steel heating tubes and a high-level condensate drainage system, which contribute to a considerable extension of equipment life and reduce maintenance requirements in the long run.

- Intensive Draining: To avoid static corrosion, any residual water contained in the steam generator must be emptied at the end of every operating day, which will ensure long life protection and consistent operation.

Water Level Sensor Corrosion Alert

Challenge: After many years of use, the water level probe sensor can corrode, and it will not detect the water level correctly.

TY-W300 Solution: To avoid downtime or any operational risks, the system also has an automatic warning mechanism that will alert the operator when abnormal readings are detected and therefore maintenance is done promptly and performance is maintained stable.

Useful Resources Regarding Heat Steam Tunnel

FAQs Regarding Tengyi Steam Heat Tunnels

What is the cost of a TY-W300 Steam tunnel?

The standard model begins at approximately $4,500 (Ex-Works). Depending upon the length of the tunnel, the arrangement of the steam generators, and the conveyor integration, final pricing will differ. Contact us to get a precise quote that suits your production requirements.

What is the best fit between the Steam tunnel and the hot air tunnel?

Your choice depends on packaging complexity and environmental needs:

Choose Steam: Suitable for full-body sleeves, irregular containers, and whenever an ultra-smooth, wrinkle-free packaging finish is required. It offers faster heat sealing speed, making it ideal for high-volume production lines.

Choose Hot Air: Suitable for products that are sensitive to moisture (such as paper containers, electronics) or in scenarios where the packaging environment must be absolutely dry. It is also efficient and convenient for handling simple, regular bottle shapes.

Please refer to the table below for a concise comparison of these two types of equipment.

Electric or Steam? Shrink Tunnel Comparison at a Glance

| Feature | Electric Heat Shrink Tunnel/Hot Air Tunnel | Steam Shrink Tunnel |

|---|---|---|

| Output Speed | Max 100 pcs/min | 100–150 pcs/min |

| Temperature | 110–180°C | 90–100°C |

| Applicable Film | POF, PE, PVC, OPS | PETG, PVC, OPS etc. |

| Shrink Effect | Good | Excellent |

| Energy Consumption | Lower (~15 kg/h) | High (27–30 kW/h) |

| Maintenance | Low maintenance compared to steam tunnels | Requires at least daily water drainage |

| Application Scope |

Suitable for moisture-sensitive products such as dry food, biscuits, and tea. Ideal for small-batch packaging lines. Used in industrial goods like tapes and electrical materials. |

Designed for high-output lines and bulk production with strict packaging quality. Best for liquid product labeling (e.g., beverages, wine). Excellent for PETG and special label shrinking. Handles irregular-shaped containers. Suitable for moisture-resistant products. |

| Equipment Cost | USD 1100–3600 depending on configuration | Approx. USD 4500 for standard TY-W300 model |

For more differences between steam vs hot air tunnels, visit this post steam heat tunnel vs hot air tunnel

Do I require an external steam boiler?

When the output exceeds 100 BPM, we advise an external generator to maintain stable pressure. A small setup or space-constrained setup can be powered by an in-built electric generator, which offers a small, plug-and-play solution.

Is it safe for refrigerated or cold-filled bottles?

Yes. The tunnel operates at 90-100°C (194-212°F), perfect with cold-filled beverages. It shrinks quickly without raising product temperature or distorting the container’s shape.

What types of shrink film materials can it handle?

PET, PVC, OPS, and PLA films are compatible. Proper shrink performance of every material is guaranteed by the adjustable steam zones.

Is it possible to have a pre-test of my product?

Yes. Send your sample bottles and sleeves to our factory to get a free test. We will provide you with high-definition videos and photos of the shrinkage results.

What is the lead time of production?

It takes 15-20 working days in standard production. The custom configurations can require up to 30 days, depending on the complexity.

Do you offer warranty and after-sales support?

The TY-W300 includes a 1-year warranty on core components. We also offer lifetime remote technical support at no cost, and spare parts are available at direct-from-factory pricing.

Discover the shrink sleeve labeling machines that pair best with this steam heat tunnel.

Explore other heat tunnels in the same category.

For more automatic shrink wrapping equipment, please click here