The TY-4525B is a high-performance shrink tunnel designed for stable and efficient shrink wrapping. It features a longer heating chamber (1500mm) for enhanced shrink results and increased throughput.

Efficient Heating System: Equipped with 12 stainless steel heating tubes, each rated at 900W, delivering uniform heat distribution and a maximum temperature of 180°C.

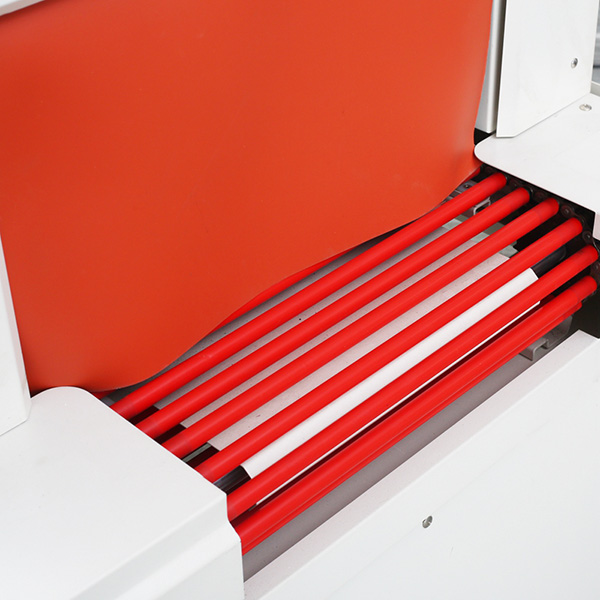

Stable Conveyor System: Powered by a 120W gearbox motor (1:25), paired with durable silicone-coated iron rollers spaced at 1cm for smooth product movement and a maximum load of 10kg.

Strong Air Circulation: Dual 750W circulation motors with 1400 RPM ensure even heat throughout the tunnel for consistent shrinking.

Intelligent Control: Features a pre-stop function for operational safety and convenience.

High Efficiency: Capable of processing 1500–2400 pieces per hour, ideal for medium to large-scale packaging needs.

Durability & Quality: Uses reputable electrical components such as CHINT contactors and Xinda relays for reliable performance.

Intuitive Control Panel

Integrated power, start, pre-stop, temperature control, conveyor speed adjustment, and emergency stop for precise and efficient heat shrink processing.

Heat Shrink Conveyor Belt:

Iron rods core with high-temp silicone exterior, ensuring smooth, efficient passage of items through heat shrink.