How does it work?

Unlike the TY-P800 automatic sleeve wrapper, this machine requires manual product feeding. You’ll need to place products onto the machine’s workbench.

From there, the TY-P500 sleever wrapper takes over:

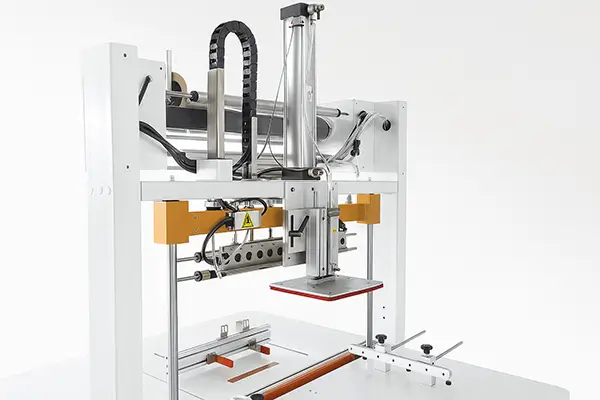

It automatically pushes the product into the wrapping position.

Once a photoelectric sensor detects that the product is in place, the automatic film wrapping process begins.

Finally, you’ll manually push the wrapped product into the heat tunnel for heating and to complete the shrink-wrapping process.

Wrapping Speed: up to 8-10 packages per minute.

Wrapping Film: PE

Heat Wrapping Tunnel Required, Yes

Precision Control

The default Inovance PLC Control Panel features an easy-to-navigate Human-Machine Interface (HMI) display. Just enter your product’s length and height, and the machine automatically computes the optimal packaging length. Plus, you can store multiple programs for quick changeovers when packaging different sizes.

The sleeve wrapper TY-P500 also include an Omron precise temperature control system for consistent and accurate heat application during sealing.

Precision & Durability

Equipped with top-quality AirTAC cylinders, our sleeve wrapping machine precisely pushes items into the wrapping position and ensures stable, durable movement of the sealing blade.

The machine body, made from stainless steel, guarantees robust, long-lasting performance.

Paired with a heat shrink tunnel, the Tengyi-P500 sleeve wrapper delivers a perfect film wrapping effect.

Before shipping, we’ll test the sleeve wrapper machine with your products and pre-set all parameters (like temperature and speed). This ensures your equipment is ready for immediate use right out of the box.

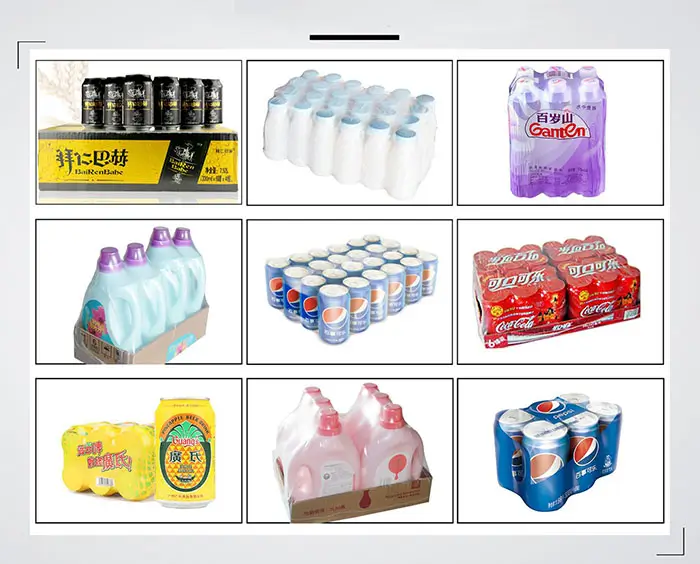

Widely used across industries such as Food & Beverage, Logistics, and Consumer Goods, among others.