Led by founder Mr. Li, who possesses over 20 years of mechanical design and shrink wrap machine manufacturing expertise, the Tengyi team is driven by experience, technology, and a passion for creating pratical, robust shrink wrap machines that effectively serve diverse industrial needs.

Since our founding in 2011, over a decade of continuous improvement and accumulated industry experience have made Tengyi particularly adept at providing precise packaging machine solutions.

We are recognized for our quality in the high-end packaging machine market in South China. Our strong reliance on customer referrals demonstrates the high level of satisfaction and trust our clients place in us.

For POF film, 130-150°C is usually sufficient. Our hot air shrink tunnel is also compatible with all other film types, capable of reaching up to 180°C (356°F) for broader applications.

Equipped with an automated sealing and cutting unit to efficiently handle high-volume production with clean, consistent results.

Compatible with center-folded film, single-wound film, sleeve wrapping, and full enclosure to fit various product shapes and sizes.

Adjustable settings allow the shrink wrap machines to handle products of different heights and widths, ideal for multi-product lines.

Tengyi mainly focuses on the manufacturing and customization of automatic sealer shrink-wrap machines for different industries. Here are the main categories:

| Aspect | L-Bar Shrink Wrap Machine | Vertical Servo Shrink Wrap Machine |

|---|---|---|

| Sealing Mechanism | L-shaped sealing bars, seals two sides at once | Vertical up-and-down sealing, centered seal |

| Automation Level | Manual, semi-automatic, or automatic | Highly automatic, minimal operator input |

| Film Handling | Centerfold film, may produce wrinkles for tall items | Centerfold film, wrinkle-free, thin seals |

| Speed | 5-30+ packages/min (varies by model) | 10-60 packages/min |

| Product Compatibility | Small, uniform items (e.g., DVDs, books, small boxes) under 11 cm in height. | Higher but less than 15cm, thin, or irregular items (e.g., bottles, tall boxes) |

| Applications | Retail, food, electronics, cosmetics (small-scale) | Cosmetics, pharmaceuticals, food, daily chemicals (high-volume) |

Shrink wrap machines offer key advantages, including enhanced product protection and appearance, as well as extended shelf life. Therefore, they are widely used in many industries, such as those listed below:

Polyolefin films (especially PP) offer excellent clarity and a glossy appearance, making them ideal for consumer product packaging that needs to showcase products.

Polyolefin shrink films are highly durable and strong. Cross-linked films (a type of polyolefin film) provide high tensile strength and exceptional puncture and tear resistance. This strength helps protect items with sharp edges and irregular shapes.

Polyolefin films are FDA-approved materials for food safety.

Cross-linked films prevent build-up on the sealing components of machines

Polyolefin films are made from 100% recyclable materials.

Polyolefin films are well-suited for printing various colors and designs, enabling branding or the inclusion of product information

In some cases, POF films require the addition of vent holes (small perforations) to allow air to escape during the shrink process. This ensures a smooth and uniform packaging surface, avoiding bubbles. Tengyi sealing wrappers include perforation settings.

Let’s be honest, figuring out the right shrink wrap machine can feel like a big decision. But it doesn’t have to be. We simplify things by giving you a full range of shrink packaging solutions, so you can stop worrying about packaging hurdles and start focusing on what you do best.

Your unique packaging challenges demand a unique solution. That’s exactly what Tengyi delivers.

Our engineers boast deep, cross-industry 10+ years of experience in crafting custom shrink packaging machines, guaranteeing a perfect fit for your specific production needs, dimensions, shapes, and wrapping requirements.

From manual flexibility to complete automation, and covering all shrink wrap machine types like L-sealers, side sealers, sleeve wrappers, and integrated systems, we don’t just sell machines—we engineer your competitive advantage.

Tengyi engineer high-performance, durable shrink wrap machines using globally trusted components like

Mitsubishi PLC,

Panasonic sensors,

Schneider (France) inverters/air switches.

Our heavy-duty, welded structures are rust and corrosion-resistant, ensuring stability, ease of use, and energy efficiency.

You get a machine that simply works—day in and day out.

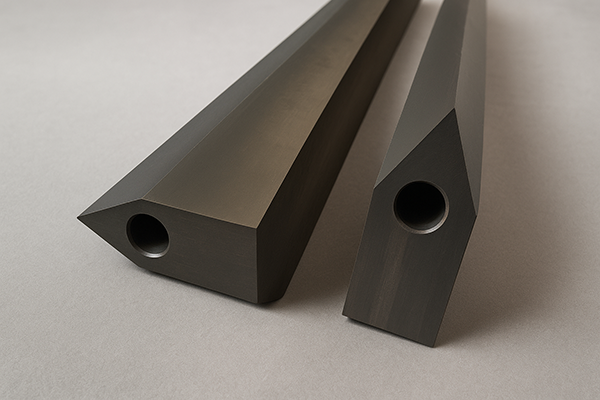

Understanding the shrink wrap machine’s core wearable components and their degradation patterns is the first step in developing an effective maintenance plan.Below are the main sealing wrapper components. High-reliability parts like PLC, conveyor belts, PC boards, and fuses are not detailed here due to their minimal failure rates.

A heat shrink packaging machine is a device used to wrap plastic film around a product and then heat it to make it shrink tightly, thereby achieving packaging

It is mainly used for securely packaging products, providing protection through tight shrinkage, preventing contamination, bundling multiple items, and facilitating the application of stickers and labels.

Using heat shrink packaging can enhance product protection (against damage, tampering, moisture, and dust), improve shelf life, provide a professional appearance, reduce packaging waste, and can be customized for branding purposes.

A heat shrink packaging machine typically includes a sealing machine and a heat source. The sealing machine closes the open end of the film, and the heat source (such as a hot air gun or a heat shrink tunnel machine) heats the film, causing it to shrink tightly around the product. For mored detail you may visit this link

Based on the level of automation, there are primarily manual, semi-automatic, and fully automatic heat shrink packaging systems.

Selecting the appropriate machine requires considering factors such as your production volume, packaging requirements, product size and shape, budget, and available space. Consulting industry experts can provide guidance. You can also read this post How to Choose the Right Automatic Shrink Wrap Machine for My Business? for a direct insight .

Key factors include the machine’s speed/production capacity, product size/shape, required film type, machine features (such as adjustable temperature settings, sealing mechanism), budget, and the space and installation requirements.

There is a wide range. Manual machines can process hundreds of products per day, semi-automatic machines can handle thousands per day, and fully automatic machines can process up to tens of thousands per day.

The key differences are in the operator involvement required, power requirements, sealing method (fully automatic and some semi-automatic use heat knives), heat source (tunnel size), footprint, cost, and daily throughput capacity.

It is highly recommended to conduct sample testing before purchasing a fully automatic heat shrink packaging machine. Testing helps determine the most suitable machine, optimal film, and whether heat shrink packaging is the right solution. TENGYI machine offer in-house testing services

The required film type depends on the product (small, large, heavy, or bottles). Thicker or sharper-edged heavier items may need thicker films. Ensure the selected machine can use readily available films. Polyolefin (POF) is a more common and preferred film type over PVC.