Packaging engineers make hundreds of decisions every year, but very few impact line efficiency and transit damage rates as directly as the choice between PE film and POF film. On paper, both are “shrink films.” On the production floor, they behave like two completely different materials. One was designed for shelf-ready presentation. The other was built to survive forklifts, vibration, and long-haul shipping.

This guide breaks down the real-world differences between PE vs POF, the machinery behind each system, and how to evaluate which film aligns with your products, line conditions, and cost targets.

What PE Heavy-Duty Bundling Actually Is

PE (polyethylene) shrink bundling is the standard for industrial transit packaging across beverages, building materials, chemicals, and other heavy products. The film is thick, typically 60 to 100 microns, and runs on sleeve wrapper machines using two film rolls instead of one. The film wraps from the top and bottom, forms a sleeve, and a center seal closes the bundle before it enters a high-temperature tunnel.

The real strength of PE comes from its cooling behavior. PE doesn’t create final tension during heating. It tightens as it cools, and that cooling is forced by a bank of adjustable-speed fans. Once the bundle exits the tunnel and fully cools, the film becomes a rigid outer structure almost like a lightweight exoskeleton. That rigidity is what keeps multipacks stable during pallet stacking and long-distance transport.

You’ll recognize PE bundling instantly by its bulls-eye openings, the circular cutouts at both ends of beverage and industrial multipacks. These aren’t defects. They’re intentional, allowing airflow, providing grip points, and reducing film consumption by 10–15%.

Where POF Shrink Wrap Fits Best

POF (polyolefin) shrink film is a thin, crystal-clear material typically between 15–25 microns. It’s used on L-sealers, which fully enclose the product with a single sheet of film before shrinking it in the tunnel. The result is smooth, glossy packaging that highlights the product, ideal for retail shelves and consumer-facing goods.

POF is the go-to choice for:

- Cosmetics

- Gift sets

- Lightweight retail products

- High-clarity packaging where appearance influences purchasing decisions

POF heats quickly and shrinks uniformly, delivering high clarity and consistent presentation. It seals cleanly with minimal odor and maintains strong mechanical performance even under stress.

Modern cross-linked POF grades are valued for their inherent strength, toughness, and superior puncture resistance.

POF also remains stable across a wide temperature range and does not become brittle in cold storage, making it a preferred material for frozen and refrigerated goods.

That is why POF excels in retail display, even though it is rarely suitable for industrial transport applications where load containment and heavy-duty strength are essential.

PE vs POF: Side-by-Side Technical Breakdown

| Specification | POF (Display Film) | PE (Transit Film) |

| Film Thickness | 15–25 microns | 60–100+ microns |

| Tear Behavior | Lower resistance than PE | High resistance; tears self-terminate |

| Shrink Mechanism | Heat-activated | Cooling-activated |

| Best Use Case | Retail display | Industrial transit |

The critical difference:

POF relies on heat to create tension. PE creates its final strength during cooling, which is why active cooling fans and longer discharge conveyors are required on a sleeve wrapper.

When PE Bundling Is the Right Choice

Beverage Multipacks

24-bottle water packs, juice bundles, beer in cans or PET, anything where cardboard trays add significant cost. Many plants eliminate $0.40–$0.60 per pack in carton expenses by converting to PE.

Building Materials

Tile stacks, flooring bundles, wood planks, metal profiles, PVC pipes. PE gives stability, weather resistance, and reliable load containment.

Chemical and Industrial Liquids

Lubricant bottles, paint cans, detergent jugs. PE’s chemical resistance prevents degradation from minor leaks.

Poor Fits for PE

- High-end retail items needing 360° clarity

- Very lightweight products under 2 kg (unstable tracking on bundler infeed)

- Temperature-sensitive items that cannot tolerate 180–220°C tunnel heat

Fast Decision Checklist for Packaging Engineers

If you’re evaluating a switch from POF or cartons to PE, ask yourself:

- Does each pack weigh more than 2 kg?

- Yes → PE gives the structural support needed

- No → POF may be the more efficient choice

- Are you currently paying for corrugated cartons?

- Yes → Plants typically achieve 18–36 month ROI after converting to PE

- Do you have 3-phase power (9–12 KW minimum)?

- Yes → Bundler can run without electrical upgrades

- No → Plan for a $3,000–$8,000 upgrade

- Is shelf appearance the primary driver?

- Yes → Stick with POF

- No → PE offers better protection and long-term economics

ROI Example: Why PE Bundling Pays for Itself Quickly

Below is a conservative case study for a beverage producer switching from full cartons to PE sleeve bundling.

| Metric | Before (Carton) | After (PE Bundling) |

| Packaging Material | Cardboard Box | PE Shrink Sleeve |

| Material Cost | $0.90 per 24-pack | $0.20 per 24-pack |

| Labor | 2.5 FTEs | 0.5 FTEs |

| Throughput | 5,000 packs/day | 5,000 packs/day |

| Labor Rate | – | $18/hr |

Total Daily Net Savings: $3,788

Breakdown:

- Labor Savings: (2.5 – 0.5) × 8 hrs × $18 = $288/day

- Material Savings: 5,000 packs × ($0.90 – $0.20) = $3,500/day

Payback Period

Bundler Cost: $93,000(roughly)

Daily Savings: $3,788

Payback: 93000/3788=24.5 working days

Most plants see savings even faster if they eliminate cartons entirely.

Stop Losing Money! Calculate your PE Bundling Payback Period Now.

You want to know the real numbers.

Switching your packaging system sounds like a big change.

But what if the change pays for itself before the end of the month?

Use the simple calculator below.

Just plug in your current operational costs.

See the instant results for your potential daily savings and payback period.

Enter your numbers below to see your immediate ROI:

Your Instant Results:

Key Equipment Requirements for PE Shrink Bundling

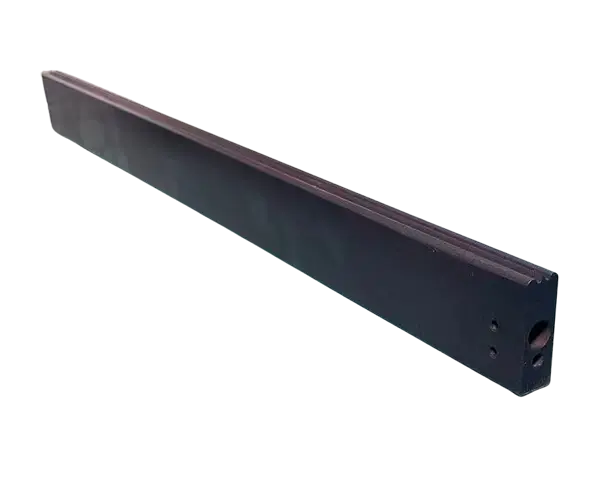

1. Hot Knife Sealing System

PE requires a continuous-heat alloy knife, PTFE-coated, running at roughly 200–260°C. Unlike L-sealers, thin sealing wires can’t handle PE’s thickness.

2. Proper Shrink Tunnel Capacity

PE absorbs more heat than POF, so the tunnel must supply higher thermal load.

Suggested tunnel specs:

- Inner length: 1.8–2.5 m

- Two or more heating zones

- Power rating above 17 KW

3. Forced-Air Cooling

Since PE shrinks during cooling, not heating:

- 4–8 cooling fans

- Adjustable air velocity

- Discharge conveyor of 1–1.5 m for final film hardening

Without forced cooling, bundles exit soft and may deform during stacking.

Machine Architecture: Sleeve Wrapper vs L-Sealer

L-Sealer System (for POF Film)

- Single film roll

- L-shaped sealing arm

- Full enclosure wrap

- High clarity, excellent for retail

Sleeve Wrapper System (for PE Film)

- Two film rolls (top + bottom)

- Straight seal bar creates an open-ended sleeve

- Heavy-duty sealing knife handles thick film

- Safest option for heavy-duty transit packaging

Bulls-Eye Packaging Explained

The open ends in PE bundles, common in 6/12/24-unit beverage packs, serve multiple purposes:

- Handles for easier carrying

- Film savings versus full-enclosure shrink

- Air escape during shrinking without perforation

For industries needing complete protection, electronics, pharmaceuticals, and sensitive components plants often choose full-wrap POF or PVC instead.

Next Steps for Different Stakeholders

For Procurement Teams

Evaluate PE bundling machines and compare film costs against your current packaging method.

For Plant Managers

Use the ROI model and daily throughput numbers to estimate payback based on your product mix.

For Packaging Engineers

Review technical specifications, sealing requirements, and tunnel configurations to match PE film with your existing or planned sleeve wrapper infrastructure.

Conclusion

PE and POF serve different purposes and understanding the difference is often the key to cutting packaging costs, reducing damage, and improving line reliability.

PE heavy-duty bundling excels in:

- Industrial transit

- High-weight multipacks

- Outdoor storage

- Long-haul shipping

- Applications where strength matters more than visibility

Plants routinely achieve:

- 60–80% reduction in material costs vs cartons

- 80%+ reduction in transit damage

- 18–36 month payback (often faster)

- More stable pallets and smoother warehouse handling

POF film, meanwhile, remains the better choice when product visibility drives sales or when package weight is too light for a sleeve wrapper.

If you’re evaluating a switch, our packaging engineers can review your product line and recommend the right combination of film, shrink equipment, and tunnel configuration for your application.

Ready to explore the right shrink film solution for your operation? Contact our engineering team for a free assessment.

Author: Mr. Li, Senior Mechanical Engineer and Founder of Tengyi, with 20+ years in the shrink wrap machine industry.