Manufacturing

Our Quality Promise

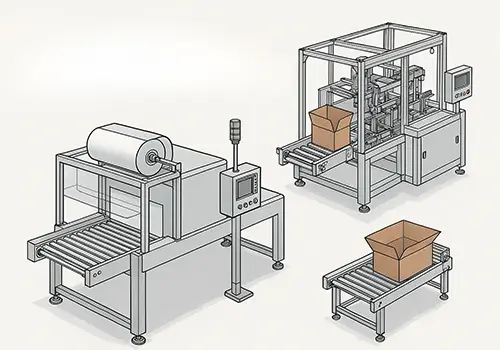

In anything we do. we understand that your packaging machine, whether heat shrink wrap machine, carton box packing machine, or other machinery, is the foundation of your operation.

As manufacturers of packaging machinery, we take control, measures, and pride in every element from the original design through to the delivery. Hence, we can sell stable, efficient, and durable packaging machines internationally.

Core Manufacturing Stages of Packing Machines

Structural Design

We leverage high-end computer-aided-design (CAD) software for 3D modeling and simulation.

With our tools and techniques we can analyze customer package machine demands, develop a conceptual design and deliver an optimized structure with good performance that can meet various customized requirements.

Material Sourcing & Quality Control

Tengyi source steel, electrical components, and heat-resistant materials from best-in-class suppliers.

We thoroughly inspect every raw material upon arrival for compliance with international acceptable practices and industry standards.

Precision Machining & Manufacturing

By using advanced technologies (laser cutting, CNC bending, robotic welding) we manufacture metal parts for package machines accurately;

We guarantee dimensional accuracy and structural integrity on all parts, supports stronger assembly.

Packaging Machine Modular Assembly

Tengyi technical team performs modular assembly of packaging machines following standardized processes.

This precise assembly ensures a stable equipment structure and smooth, error-minimized operation

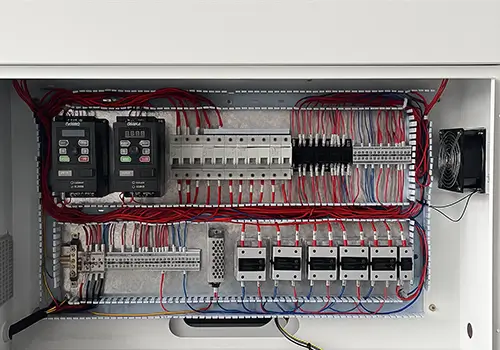

Electrical and Control System Integration

Powerful electrical components—PLCs, HMI touch screens, sensors, and heating elements—are carefully wired and interconnected in the package machines.

We follow electrical safety standards to provide stable, proven, and ultimately user-friendly operation.

Quality Inspection and Performance Testing

Before leaving our factory, every packaging machine goes through a number of quality tests and simulated operations.

We evaluate everything from temperature uniformity to conveyor tracking, safety functions, and anything else that confirms the machine will perform to the designed specifications.

Security and Logistics

All tested packaging equipment undergoes professional and secure wood case packaging, utilizing shock-proof and moisture-proof materials to ensure the equipment remains in perfect condition during transit.

Tengyi's Streamlined Order-to-Delivery Process

Requirements & Solution Design

Understand your package machine needs (dimensions, speed, film type, etc.), then recommend and quote the ideal machine

Step 1

Contract & Deposit

After confirming the contract(including detailed machine solution plan, price, lead time, etc), production begins upon deposit

Step 2

Production & Sample Matching

You send us samples (e.g., bottles) for precise machine configuration. Production typically takes around 30-40 days.

Step 3

Final Testing & Delivery

The packing machine will be fine-tuned and tested to contract specifications once it is ready.

When we show the customers the successful effectiveness and receive the last payment, we will pack the machine for shipment.

Installation Support & Training

For overseas clients, we provide video installation guides and maintenance instructions to help with equipment setup and debugging.

Discover TENGYI Quality: Schedule a Factory Visit or Equipment Consultation

Please come visit the TENGYI factory to witness our manufacturing capabilities in action. Or, meet with one of our expert team for a one-on-one consultation to explore all the ways we can provide packaging machine solutions for your business