Factory Direct Automatic Industrial Shrink Wrap Machines: High-Speed, Precision Sealing & Custom Solutions.

Stop overpaying resellers. As a factory-direct industrial shrink wrap machine manufacturer, we engineer automatic industrial shrink wrap systems specifically for high-volume lines that demand 24/7 reliability—cutting your costs by 30%

Weather-Proof Protection

Creates a tight, reliable seal that blocks dust and moisture.

Ideal for food, pharma, and any application requiring extended shelf life and tamper-resistant packaging.

Retail-Ready Clarity

Engineered with Zero-Fish-Eye shrinking for crisp, high-transparency results.

Delivers a clean retail finish that elevates product presentation on the shelf.

Boost Throughput

Automates critical wrapping steps to remove process bottlenecks.

Achieves consistent high-speed output while reducing reliance on multiple operators.

Which Automatic Shrink Wrap System Fits Your Line?

Stop guessing. Choose the right technology based on your speed and product size.

Automatic L-Bar Sealer Series

Small to mid-sized boxes

Limited by L-bar size

contract manufacturers,

medium-volume production factories.

Side Sealer Series

The Smart Choice:

“Don’t overpay for 100ppm speeds you don’t need. Our side sealer TY-500T delivers continuous ‘Infinity Length’ sealing for standard production lines at 1/3 the cost of high-speed box-motion machines.

Sleeve Wrapper Series

Specialized Shrink Packaging Solutions

Shrink Sleeve Labeling Machine

Engineered for versatility. Handles any bottle shape at up to 120 BPM. The scalable choice for growing cosmetic brands.

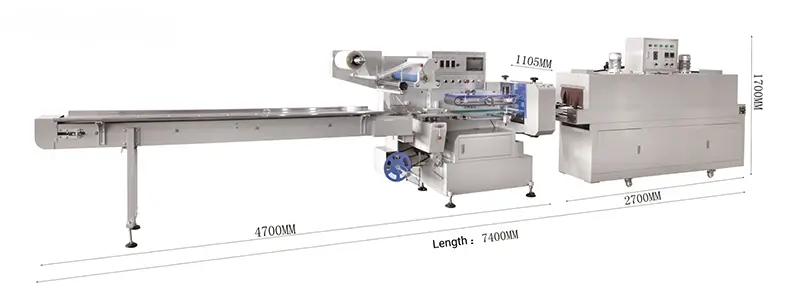

Shrink Flow Wrapper

Designed for speed and consistency.

Perfect for standardized products requiring rapid throughput (60-120 PPM).

Don't Forget the Engine: Precision Heat Tunnels

Hot Air Tunnel

Hot Air Heat Tunnel – like TY-4525, 5030, Uses 8–9 electric heating tubes to circulate hot air at 120–180°C, ensuring quick and even shrinkage of POF, PE, and PVC film

Steam Heat Tunnel

Steam Heat Tunnel(TW-300) – Uses steam at 90–100°C to gently shrink PETG film. Suitable for high-speed mass production of moisture-repellent and heat-sensitive products

Ready to Optimize Your Packaging Line?

Proven Performance in Your Industry

Cosmetics & Pharmaceuticals: Flawless Presentation.

“Zero-Fish-Eye” technology ensures crystal clear retail presentation. Tamper-evident wrapping for consumer safety and compliance.

#TamperProof #HighClarity

Food & Beverage:Fast wrapping, always fresh.

1.Lock in freshness

2.Tamper-proof protection

3.Speed up the whole chain

For more details on shrink packing for beverages and bottles, please check the link below:

E-commerce & Logistics: Random Size Integration.

Intelligent sensors detect product size automatically.

E.g TY-800A shrink bundler wrap a basketball followed by a shoe box without changing the machine settings.

#AutoSizing

#LogisticsEfficiency

Engineered for ROI: The Tech Specs

Key Components List (Ensuring Stable Operation)

PLC:INVT / Mitsubishi / Siemens

Inverter: Schneider

Temperature Controller: Omron

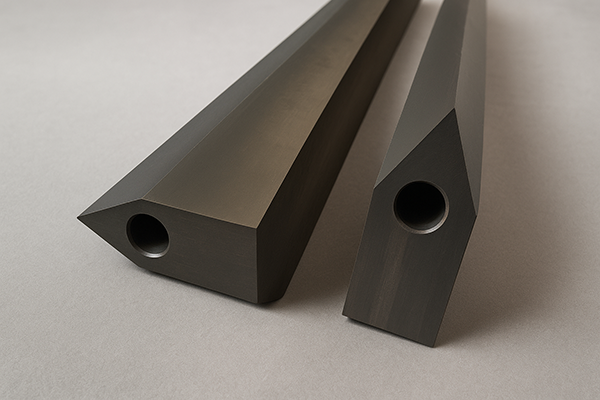

Sealing Blade: Teflon Alloy (Lifespan: 2 Million+ cuts)

Built to Last: Premium Components

Unlike cheap units that fail in months, our machines use heavy-duty parts designed for years of 24/7 operation.

Teflon-Alloy Sealing Blades

The Tech: Solid alloy blade coated with premium Teflon.

The Benefit: Ensures a clean, smoke-free seal every time.

Lifespan: Tested for 2 Million+ cuts before replacement.

High-Temp Silicone Pads

The Tech: Industrial-grade heat-resistant silicone.

The Benefit: Provides perfect cushioning for airtight seals.

Feature: Reversible design doubles the lifespan.

The “Hidden Cost” Killer: Consistent Speed, Reduced Labor, Real ROI

For example, the old setup from a phone screen protector factory required three people to shrink-wrap phone screen cases.

With the TY-5545 shrink wrap line, only one operator is needed.

1 operator feeds the products in, and the machine handles wrapping, sealing, and shrinking on its own.

That cuts two workers from the line, saving at least $20,000 annually in labor costs.

Cleaner seals.

Fewer mistakes.

A smoother, more premium look on every pack.

This upgrade cuts labor waste and keeps production running at full speed.

Not Just a Machine, A Partnership.

Let’s be honest, choosing a machine is hard. We simplify it.

Custom Engineering

10+ years of cross-industry experience.

Global Components

Mitsubishi, Panasonic & Schneider inside.

Remote Diagnostics

Smart PLC for instant troubleshooting.

The "Zero-Downtime" Guarantee

We ship critical spare parts within 24 hours. Plus, every machine includes a Free "First-Aid" Parts Kit (Heating elements, cutters, relays) so you never stop running.

Live Machine Audit (Real-Time Demo)

Don't trust edited videos? Book a Live WhatsApp Video Call. We will take you to our workshop floor right now, run your specific product on the machine, and show you the sealing result in real-time.

24/7 Global Video Support

Stuck with settings? Get instant WhatsApp Video Support from the engineers who built your machine. We solve problems in minutes, not days.

Case Study

Cosmetics: 4 Years of Partnership

Premium Packaging for a Top Global Brand

Result: Zero Fish-Eyes & Crystal Clear Presentation.

Food Industry: Bakery Giant’s Upgrade

Meeting Holiday Demand Without Extra Staff

Result: +150% Production Output Boost.

Electronics: Breaking Bottlenecks

From Manual Labor to High-Speed Automation

Result: 500% Speed Jump for Screen Protectors.

Cosmetic: Eliminating the Labor Bottleneck

From Manual Labor to 100 BPM Automated Precision.

Result: 100% Speed Jump & 3 High-Cost Laborers Removed.

“This system solved our longstanding packaging appearance problem, and the stability and speed of the machine assure that we can handle bigger orders. Our product presentation has significantly improved since installation.”

Mr. Wang, the owner of Shenzhen Nima Electronics Co., Ltd.

FAQ Regarding Automatic Industrial Shrink Wrap Machines

What are the main differences between manual, semi-automatic, and fully automatic heat shrink packaging machines?

The key differences are in the operator involvement required, power requirements, sealing method (fully automatic and some semi-automatic use heat knives), heat source (tunnel size), footprint, cost, and daily throughput capacity.

Can I run samples or testing on the machines before purchase?

It is highly recommended to conduct sample testing before purchasing a fully automatic heat shrink packaging machine. Testing helps determine the most suitable machine, optimal film, and whether heat shrink packaging is the right solution. TENGYI machine offer in-house testing services

What Defines a True "Industrial" Shrink Wrap Machine?

Unlike standard commercial units, our industrial shrink wrap machines are specifically engineered for continuous 24/7 operation.

While basic models and manual heat guns simply apply heat to shrink the film, our professional-grade systems — including L-bar sealers, side sealers, and shrink bundlers — are equipped with heavy-duty conveyor systems and advanced PLC automation.

This design enables them to reliably handle thousands of cycles per day without overheating or downtime.

The result is consistently secure, tamper-evident packaging ideally suited for high-volume production environments.

Commercial Shrink Wrap Machine vs. Industrial Shrink Wrap Machine: What's the Difference?

In our 20 years of experience in the shrink wrap machine industry, we think the main differences lie in Durability and Production Capacity.

Commercial Units: Often manual or semi-automatic “chamber” machines designed for intermittent use (5–10 packs/minute). They are lightweight and best for small shops.

Industrial Machines (Like Our TY-Series): Engineered for 24/7 continuous operation. They feature heavy-duty motors, PLC automation, and rugged frames. Whether it’s a fully automatic L-Bar TY-5545 (30-60 ppm) or a Continuous Side Sealer TY-500T, industrial systems integrate seamlessly into conveyor lines to handle high volumes without overheating or downtime.

Do You Really Need High-Speed Side Sealers?

In our 20 years in the packaging industry, I’ve seen too many factories overspend on high-speed machines they don’t need.

Many manufacturers sell expensive “Box Motion” side sealers ($30k+) capable of 100ppm, when their line only runs at 30ppm.

Our Standard TY-500T ($10k range) handles the same unlimited length products with the same perfect seal quality—saving you thousands in capital investment.

Why do your machines recommend POF film over PVC?

High Clarity: POF is crystal clear, enhancing shelf appeal.

Safety: FDA-approved for food contact; PVC is not.

Durability: POF is multi-layered and puncture-resistant, unlike brittle PVC.

Eco-Friendly: 100% recyclable.

Note: Our machines handle both, but POF delivers the best ROI.