Présentation de la machine d'emballage sous film rétractable à changement automatique One Touch TY480.

Mettez en valeur vos produits électroniques haut de gamme, vos produits cosmétiques de luxe, dans un emballage impeccable et cristallin - pas d'oreilles de chat, pas de lignes de scellage visibles, une présentation impeccable, prête pour la vente au détail.

S'appuyant sur des décennies d'expertise dans la conception et la fabrication de lignes automatisées d'emballage sous film rétractable, Tengyi fournit des solutions personnalisées à tous les secteurs d'activité afin de maximiser l'efficacité et d'améliorer l'impact de la marque.

Caractéristiques principales

Changement de format entièrement automatisé

D'un simple clic sur la recette et le format, notre positionnement servocommandé et notre contrôle manuel de la tension du film permettent de changer de produit en moins de 3 minutes.

Rendement élevé

Production standard de 400 à 500 pièces/heure (maximum théorique de 654 pièces/heure) avec un taux de réussite supérieur à 98%.

Finition Premium

Film POF brillant et sans plis, résistance du film réticulé, clarté cristalline.

IHM intuitive

Automate Siemens et écran tactile couleur avec interface chinois/anglais pour faciliter la configuration et la surveillance.

Conception modulaire robuste

Cadre en acier soudé avec fenêtres à accès libre et capteurs de sécurité ; composants homologués UL provenant du monde entier.

Remplacement du rouleau de film rapide

Un système de rouleau de film à axe pneumatique pour des changements de film en toute sécurité, sans aucun outil.

Un emballage cohérent et professionnel

L'alimentation en film, la formation des sachets, la découpe des coins et la rétraction, entièrement automatisées, permettent d'obtenir des emballages prêts pour la vente au détail et reproductibles.

Prix et livraison

- Prix départ usine : 43000 USD/unité ( Inclure la machine de rétraction + le tunnel de rétraction)

- Livraison : 45 jours ouvrables après le dépôt

- Paiements : 50% dépôt, 50% avant expédition

- Garantie : Un an

Tengyi fournit une installation guidée par vidéo, ainsi qu'une assistance à distance à vie pour l'installation, la maintenance et le dépannage.

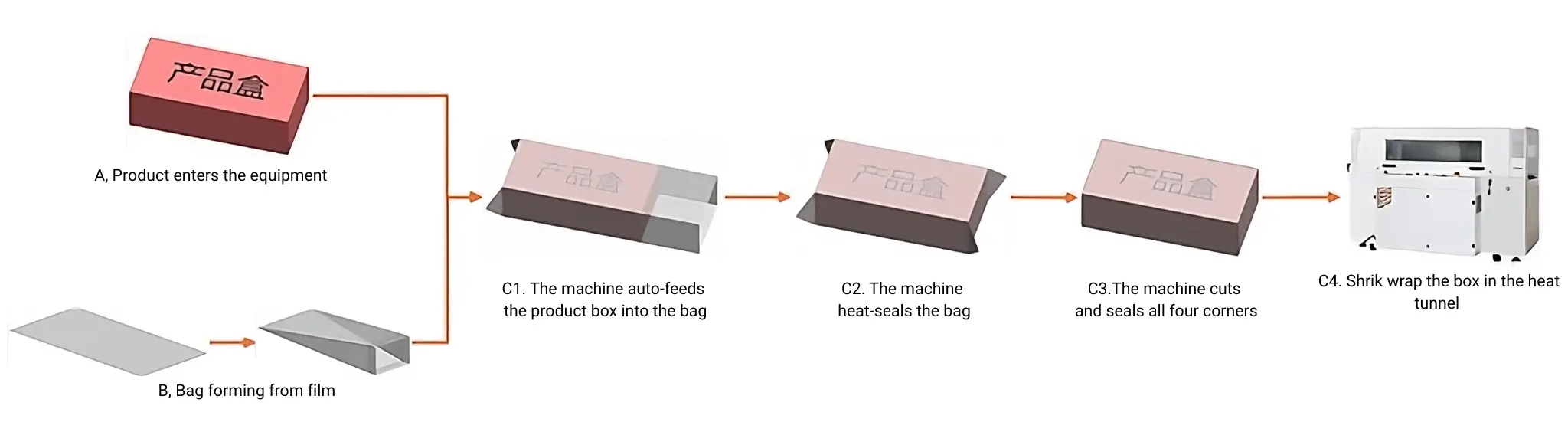

Processus d'emballage par rétraction

Processus d'emballage

Alimentation simultanée des boîtes et fabrication des sacs

- Le convoyeur de levage charge les boîtes tandis que l'unité de formation des sacs crée des sacs en synchronisation, le tout coordonné par l'automate programmable.Insertion de produits

- La machine introduit automatiquement les boîtes dans les sacs.Scellage et découpage à chaud

- La lame chaude scelle et coupe le sac.Scellement des angles

- La machine coupe et scelle automatiquement les quatre coins du film.Emballage sous film rétractable

- Les produits passent par un tunnel de thermorétraction.Décharge

- Les produits finis emballés sous film rétractable sortent de la ligne.

Des composants de première qualité et une fabrication de précision garantissent une performance sans faille.

| Non. | Composante clé | Marque | Remarques |

|---|---|---|---|

| 1 | Cadre | - | Cadre soudé à tubes carrés, revêtement extérieur par poudre et fenêtres acryliques transparentes. |

| 2 | Plaque de coupe et de découpe | - | Lame en acier à outils SKD-11, plaque de matrice en caoutchouc à haute température |

| 3 | Vis à billes et rails linéaires | HIWIN / TBI | Qualité de précision |

| 4 | Cylindres, électrovannes, raccords rapides | AIRTAC | - |

| 5 | Blocage de porte et capteurs photoélectriques | OMRON / Panasonic | L'interrupteur d'interverrouillage d'OMRON augmente le niveau de sécurité global |

| 6 | Système de contrôle | Basé sur un PLC | Siemens PLC |

| 7 | Panneau IHM | Siemens | - |

Gros plan sur les principaux composants de la machine d'emballage sous film rétractable TY480

Forte isolation, toucher sûr

Vitesse variable du convoyeur : 0-20 m/min

Taille mécanique: 1900×1100×1300 mm

Taille de la chambre: 1600×500×300 mm

Paquet maximum: 1300×400×250 mm

Capacité: 1500-3000 pcs/hr

Puissance: 3PH 380V 50Hz 18 kW

Lignes directrices pour l'approvisionnement en films

Type de film : FOP réticulé à double couche (0,019 mm d'épaisseur)

Largeur du film : Hauteur du produit + longueur du produit + 60-80 mm

Dimensions du rouleau : Diamètre intérieur 76 mm ; diamètre extérieur < 250 mm

Exigence de qualité : N'utilisez que le film rétractable spécifié pour garantir des performances constantes.

Critères de qualité de la boîte rétractable TY480

- Les six faces planes doivent être lisses et exemptes d'égratignures, sans traces sur les douze bords ou autour des huit coins supérieurs.

- La ligne de scellement doit être droite. Mesurée par rapport à une référence horizontale, toute inclinaison doit être ≤1,5°, et le joint doit se situer à ±3 mm de la mi-hauteur de la boîte.

- Aucun "stringing" ou film tiré n'est autorisé au niveau des scellés ou de la ligne de coupe.

- Les positions des joints d'angle doivent être alignées avec les bords correspondants sur l'axe de hauteur ; écart ≤3 mm.

- Les trous d'aération pratiqués pendant la rétraction doivent être des micro-aérations de <0,1 mm - propres, nettes et efficaces pour l'imperméabilisation à l'eau et à la poussière.

- Le joint doit résister à une déchirure d'au moins 2,5 kgf sans se rompre.

Application

La machine à emballer sous film rétractable TY480 traite tous les articles qui nécessitent un film protecteur extérieur haut de gamme - boîtes de médicaments, boîtes d'aliments, boîtes de produits de santé, boîtes de cosmétiques, boîtes de thé, boîtes de smartphones, boîtes de batteries de téléphone, boîtes de banques d'alimentation, boîtes de câbles de données, lecteurs MP3/MP4, tablettes PC et autres produits similaires - offrant une résistance à l'humidité, une protection contre l'humidité et une finition attrayante, tout en conservant le contenu intact.

Installation d'une machine d'emballage sous film rétractable TY480 dans l'usine du client

Étude de cas : Application de la machine automatique d'emballage rétractable TY480 aux boîtes cadeaux haut de gamme

En plus d'améliorer la vitesse de production, le TY480 permet d'obtenir une finition propre, cohérente et professionnelle des paquets cadeaux. Leur efficacité opérationnelle pendant la période de pointe des fêtes de fin d'année a permis de satisfaire davantage de clients et d'améliorer leur réussite.