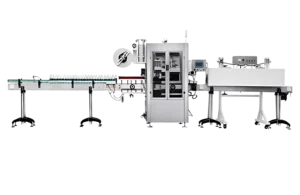

The DLL-450A shrink bundling machine is designed for fully automatic packaging lines for bottled products like beer, soft drinks, purified water, fruit juice, and dairy. Unlike other shrink bundling machines, it achieves a speed of 20 packs per minute. This is more than 2.5 times faster than conventional Sleeve wrappers.

Automated processes, such as infeed conveying, film wrapping, sealing, cutting, shrinking, cooling, and shaping, are integrated into the system.

Key Capabilities

- Automatic control of shrinking and sealing temperatures, adjustable as needed.

- High-Speed Output – Up to 20 packs per minute

- Constant temperature seal knife, coated with Teflon, ensuring flat and firm cuts.

- Controlled by PLC for precise automation.

- Touch screen operation, user-friendly interface.

- Tray-Free Design: Accommodates Diverse Bottle Sizes and Bundle Arrangements.

Shrink Bundler DLL-450A Working Principle

The DLL-450A Heat Shrink Film Packaging Machine is an intelligent, high-speed shrink bundler specifically designed for the bottled water and beverage industries. PE shrink film is used to tightly bundle bottles for easy transportation and retail display.

A smart PLC control system controls the machine and integrates photoelectric sensors for real-time detection, which allows seamless automation from bottle feeding to final packaging.

🔁 Here is how it works:

- Continuous Bottle Infeed – Bottles are fed into the system via a conveyor.

- Separation and grouping of bottles – Divider plates and gates organize bottles into predefined groups (e.g., 6, 12, 24).

- The PE shrink film is automatically wrapped around bottles by push rods.

- Cutting and sealing – Heat the blades to seal and cut the film.

- Packages enter a shrink tunnel (TY-5030 ), where hot air ensures bottles are tightly and uniformly enclosed.

Bottle-Group Alignment Module

Servo-driven finger guides instantly arrange loose bottles into a precise row-and-column matrix for the shrink wrapper.

Stainless steel frame with brass inserts handles wet, high-speed lines without jams.

Quick-release blocks enable fast changeovers.

Center-Feeded Film Stand

Servo-sync unwind keeps your film tight and on track.

Balanced center roll needs no realignment after changes.

Tool-free shaft swapping can be completed in under two minutes.

Powering the Beverage Industry