Industry: Large Cosmetic OEM/ODM Factory (Suzhou Sunrise Cosmetics Co., Ltd.)

Location: Suzhou, Jiangsu Province, a place where labor is expensive.

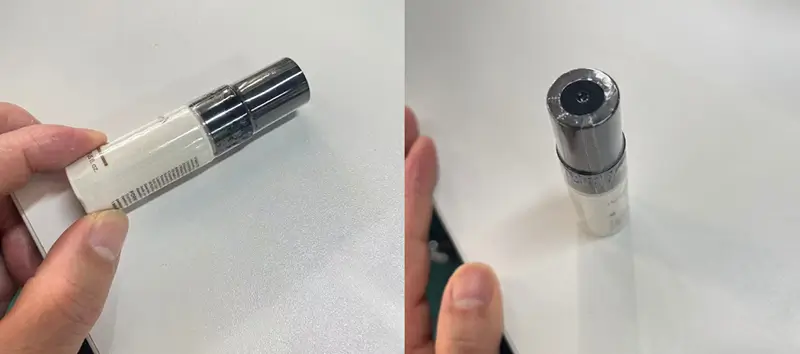

Product: Vials of perfumes, 1.5 cm diameter, 8 cm high, PET film wrap.

This Suzhou producer had an excellent product and a solid order pipeline, but the last packaging stage was bringing them down. Three employees were hand-sleeving PET labels at the end of the line, which is a bottleneck that literally could not be scaled. And, to make it worse, the product had to be sealed at the top and bottom, with a small window left unsealed in between, something that can only be done with high-precision sleeving equipment.

And the target output? A set of 80 bottles per minute, which the manual process had no hope of achieving.

The factory required a solution that would automate this complicated shrink sleeving process; without losing precision or presentation standards.

Tengyi’s Customized High-Efficiency Sleeving Solution

To reduce reliance on manual labor and meet the precise sealing requirements for the bottle bottom and cap, Tengyi deployed two independent high-speed automated shrink sleeve labeling lines, featuring a crucial customization: precision control and a newly designed vial bottom-sealing module.

1. The Star: Tengyi Fully Automatic Shrink Sleeve Labeler (2 Units)

Each shrink sleeve labeler is powered by a Panasonic servo motor, ensuring tight, closed-loop motion control. The system, together with Panasonic PLCs and OMRON high-sensitivity sensors, has a steady accuracy of ±1 mm even on speeds as high as 100 BPM.

The combo of stainless steel architecture with aluminum alloy upholds the GMP standards and provides long-term high-speed support.

2. The Innovation: Customized Bottom-Wrapping Module

Here’s where this project really stands out.

Tengyi designed a special bottom-wrapping unit that was placed between the labeler and the main heat tunnel. It pre-sleeves PET film to the bottom of the vial and gives it a partial steam-shrink. This holds the film straight until the vial is pushed into the main tunnel so that the top and body are shrunk without causing wrinkles or misalignments.

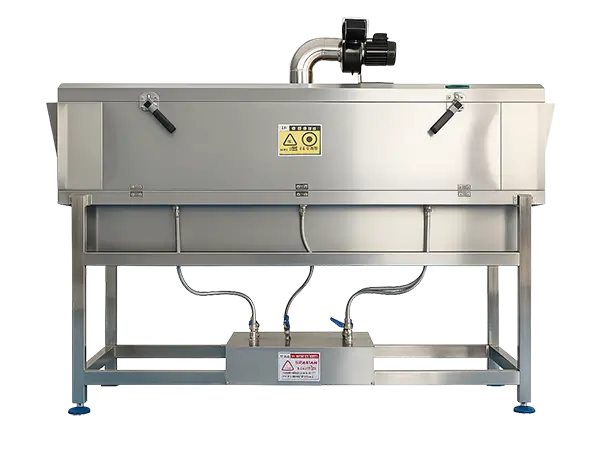

3. The Partner: Steam Heat Tunnel + 24 kW Steam Generator

The tunnel features:

- 304 stainless steel frame

- POM slat chain conveyor for stable high-speed movement

- A 24 kW steam generator, with stable steam pressure of 0.4 MPa, sufficient to allow constant production of 100 BPM.

Despite the long distance of 1300km between Guangdong and Suzhou, the after-sales team of Tengyi arrived in time to install, calibrate, and fine-tune the two-stage shrink process on-site.

Implementation & Final Results

| Metric | Before | After (Tengyi) | Impact |

| Packaging Speed | Labor bottleneck | 100 BPM per machine | 100% increase |

| Labor Needed | 3 workers | 0 workers | 3 high-cost laborers removed |

| Labeling Success Rate | Inconsistent | 99.5% | Significant reduction in rework/waste |

| Investment | – | $14,523.00 | Labor savings lead to high ROI. |

| Component Reliability | Standard | Panasonic/Mitsubishi/Schneider | Low TCO |

The finished look of the shrink sleeve label as below

Client Feedback

“Our product fitted well with the customized bottom-seal solution. The speed of 100 BPM at 99.5% accuracy was way beyond our expectations and the on-site assistance provided by Tengyi ensured a smooth shift.”

– Mr. Zhang Xiao, Production Operations Director, Suzhou Sunrise Cosmetics Co., Ltd.

Conclusion & CTA

With the high labor requirements of cosmetic OEM/ODM factories or with complex PET sleeving needs, Tengyi has the solution to the problem with its high-speed sleeving line with the customized bottom-wrapping module and high-quality global components. This case is a testament that Tengyi provides not only speed, but also precision, customization, and guaranteed regional service, which ensures that your investment of $14,523.00 will yield a high, quick payoff.

Ready to automate?

Are you looking to eliminate high labor costs or automate complex top-and-bottom sealing?

Click below to contact our senior automation engineers for a100 BPM Customized Sleeving Solution and an Accurate ROI Analysis tailored to your factory.

Discover More Applications

Explore other success stories and applications of our automatic shrink wrap machine by clicking here.