Case Sealer

Tengyi manufactures a series of advanced case sealers since 2014, aimed at helping customers achieve higher packaging production efficiency, lower operating costs, and superior packaging quality. Whether customers are dealing with uniform case sizes or randomly mixed box types, we have customized solutions to meet your needs.

Why Choose Our Case Sealers?

— Core Advantages & Return on Investment

For large-scale companies that pack over 3,000 units daily, introducing an automated case sealer will significantly enhance your packaging operations and offer numerous core advantages.

Increase production efficiency and output

Automated case sealers, such as the TY-ZG500, TY-JB500L, etc, can seal 6-8 boxes per minute, equivalent to 2-3 times the output of manual labor within the same timeframe.

This effectively solves slow packaging issues, making these case sealers particularly suitable for high-volume, repetitive packaging needs like those in large logistics enterprises

Significantly lower operating costs

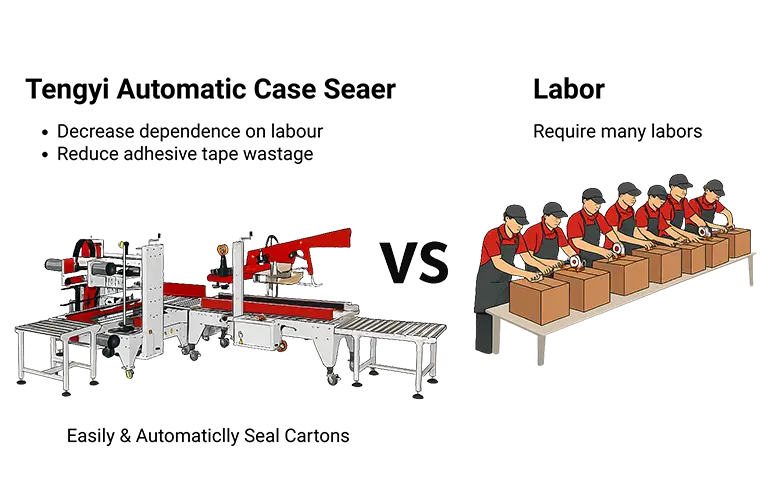

Decreased dependence on labor: TENGYI automated case sealers(TY-ZG500, TY-JB500L etc), along with case erectors(TY-K200) and case packers into continuous packaging lines can replace numerous employees per shift, allowing labor to be put to more valuable use.

Material savings: Case sealers allow you to apply tape or hot melt adhesive to cartons consistently, which can help reduce waste, prevent unnecessary seals and may save approximately 26% in materials in certain period.

Enhance packaging quality & product protection

Consistency and aesthetics: Automated case sealing ensure that the boxes are square, seals are flat, and tape is smooth and in the correct position, positively influence the appearance of the package and brand impression.

At the same time, stronger seals protect products from being damaged during transport, eliminating losses, and minimizing the chance of tampering.

Decrease employee injuries and downtime

Remove the hazard of work-related injuries resulting from repetitive box sealing motions by laborers, like wrist, back, and neck strain.

Decrease associated insurance claims and loss of productivity

How A Case Sealer Works

Whether automated or semi-automated, case sealers operate on fundamentally similar principles. Let’s explore these principles below.

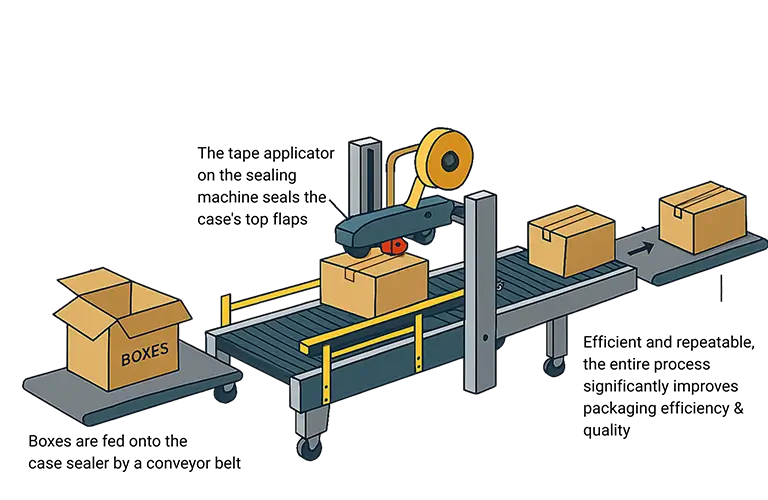

In fully or semi-automated production environments, cases are supplied to the machine and advanced via a belt drive.

On detection of a carton, the case sealer activates and the devices on top of the machine press the flaps down. Meanwhile, the tape applicator automatically lowers and applies adhesive tape to the top flaps, producing a custom cut length of tape to complete the case-sealing process.

This whole case-sealing process is highly efficient and highly repeatable,and greatly enhances the total efficiency and quality of packaging process.

Perfectly Designed for Your Packing Operations.

Need Custom Carton Sealer Solutions?

Contact Tengyi Experts today for tailored case sealer designs and manufacturing that meet your unique packaging needs.

Seamless Integration — Your Packaging Line Solution

Tengyi case sealers are designed for seamless integration with your existing packaging production lines, whether as standalone units or as part of a complete automated system.

Modular and Flexible Design

- Tengyi case sealing machine have a modular design with interchangeable modules, including:

- Infeed and Conveyor Module

- Top Flap Folding Module

- Sealing Application Module

- Compression Module

- Control System Module

- Discharge Module

- The modular approach on case sealers allows for easy customization and adaptation to handle different case sizes.

Smooth integration

The modular design and standardized interfaces facilitate easier mechanical and electrical integration with upstream equipment (e.g.,case erectors, case packers) and downstream equipment (e.g., palletizers).

Customization Options

Tengyi carton sealers can be configured with different levels of automation, from manually adjusted for uniform cases to “random” sealers with automatic size adjustment.

Our Case Sealer Series — Diverse Solutions to Meet Your Needs

We offer a comprehensive range of carton/box/semi-automatic case sealers, with various models available from semi-automatic to fully automatic, ensuring there is always one suitable for your specific packaging requirement

By Level of Automation

- Semi-Automatic Case Sealers: The operator manually folds the box flaps and feeds the box into the machine, and the machine completes the top and bottom sealing. e.g TY-YZ500

This is suitable for scenarios that require human intervention. - Fully Automatic Case Sealers: The machine automatically folds the box flaps and completes the sealing, achieving a high level of automation. Such as TY-ty-zg500, TY-JB500L

Recommended for manufacturers with high volume packaging demands.

By Case Size Consistency

- Uniform Sealing machine: Suitable for continuously processing boxes of the same size and shape, aimed at high efficiency.

Example models: TY-ty-zg500, TY-JB500L - Random box Sealers: Automatically measure and adapt to different box sizes, without the need for manual adjustment. Highly suitable for e-commerce and multi-product packaging operations. At the Tengyi factory, such kind case sealers are custom-made.

Other Classification

*Classified by Sealing Method and Belt Type:(Top & Bottom Belt like TY-TY-ZG500, TY-JB500L/Side Belt, etc)

*Sealing methods: Adhesive tape or hot melt glue

All of the above are customized according to specific industry needs.

To learn more about the classification of carton-sealing machines, please visit this blog post case sealing categories

Key Features of Tengyi Case Sealers

User-Friendly Control Panel

Clearly labeled buttons for Power, Start, Stop, and Run Indication ensure straightforward control.

Enhanced Safety: Prominent Emergency Stop button and visible safety warnings for immediate, secure shutdown.

Automatic Carton Sealing

Efficient & Consistent Packaging: Automates carton sealing for high throughput up to 8 cases per minute.

Precision Engineering: Features smooth conveyor belts and advanced sealing applicators.

Built to Last: Robust construction ensures reliable, long-term performance.Videos of Our Automatic Case Sealing Packaging Lines

Widely Applicable Across Various Industries

- Food and Beverage Industry

- Cosmetics Industry

- Household chemicals

- Pharmaceuticals

- Consumer Goods like electronics

- E-commerce & Mail Packages

Why Choose Tengyi as Your Case Sealer Supplier?

Leveraging more than 10 years of experience across different industries, we deliver meticulously tailored case sealer solutions designed for your unique sector’s needs.

Hassle-Free After-Sale Service

Supply of Spare Parts.

Tengyi will provide case sealer spare parts, like adhesive tape cutting blades, support on a cost-price basis.

Repair/Modification Plan Assistance

A Repair/Modification Plan for the carton sealing machine will be provided to help support you with repairs.

If you carry out repairs on-site overseas and this involves the support of engineers from Tengyi, you will pay for the visa, airfare, hotel accommodation, and labor costs.

Technical Training

Video materials will be supplied for training (for use in installation, debugging, etc).

If you would like to have training on-site overseas, you will pay for the visa, airfare, hotel accommodation, and labor costs for the Tengyi engineers.

Remote diagnosis and troubleshooting

We will provide a video explanation, etc., to help support the customer in getting used to the case sealers or to help solve problems you are having using the case sealers from Tengyi

Our ultimate goal is to ensure the case sealer is stable, user-friendly, and durable, which helps your business.

Related Resources

Case Study

Applications of Case Sealers in the Cosmetics Industry

FAQs Regarding Tengyi Case Erector

What's Case Sealer?

A carton sealing machine, sometimes referred to as a case sealer, box sealer, or taping machine, is packing machinery that is automated and used to seal and close corrugated cardboard boxes.

The machine usually seals cartons or boxes using tape or adhesive to provide closure for transportation, storage. The machine plays a significant role in a automatied packaging process.

What is the difference between semi-automatic and fully automatic case sealers?

With semi-automatic case sealers, like TY-YZ500, the operator must manually load or fill the corrugated cardboard boxes, close the top flaps, and then feed the boxes into the sealing machine to be sealed.

Fully automatic case sealers like TY-ZG500 do not require an operator they can automatically do everything including closing the top flaps of the boxes providing a more seamless solution than a semi-automated solution, and is ultimately designed for higher volume production needs.

What is the difference between top-and-bottom case sealers and side-belt case sealers?

The primary distinction is in the box replenishing and sealing process:

Top and Bottom Carton Sealers: These styles of machines seal the top and bottom flaps of a box. Following that, the box then moves on a conveyor, where rollers or belts press the flaps down onto the tape. Top and bottom carton sealers work with a wide range of box sizes, especially heavier boxes. Most Tengyi case sealers like TY-zg500, TY-JB500L are of such kind

Side Belt Carton Sealers: This type of carton sealer utilizes belts on the sides of the box to hold it securely while the tape is being applied to the top and bottom. They are especially suitable when working with lighter, taller, or narrower boxes, as the side belts will properly adapt to the box size and shape to keep the box stable. In Tengyi, it’s a customized option.

Q: What kind of daily maintenance does a carton sealer need?

Check Mechanical Parts: Check the rotating and lifting mechanical parts frequently to ensure they are moving properly, and tighten any loose screws.

Leaks: Check for any leaks in electrical wires and pneumatic (air) systems.

Sensors: Ensure sensors are clean and properly aligned.

Lubrication: Lubricate all moving parts with the appropriate lubricants.

Regular Cleaning: Clean the machine regularly, especially for sanitation.

Doing these daily steps will create longevity in your carton sealer and keep it running smoothly.