L bar Sealers

Automatic L Bar Sealers Manufacturer Since 2014

So far, 40% of the equipment produced by Tengyi consists of automatic L-bar sealers with heat shrink tunnels. TENGYI’s L-bar machines are capable of automatic feeding, sealing, and film cutting, mainly designed for for industrial use, ensuring fast and efficient packaging to meet medium to high-volume shrink wrap demands.

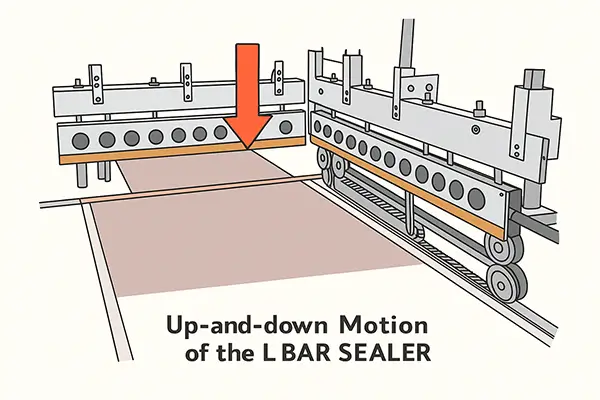

Automatic L-Bar Sealer feature an L-shaped sealing bar and operate in two distinct motion types as below

Scissor-Type

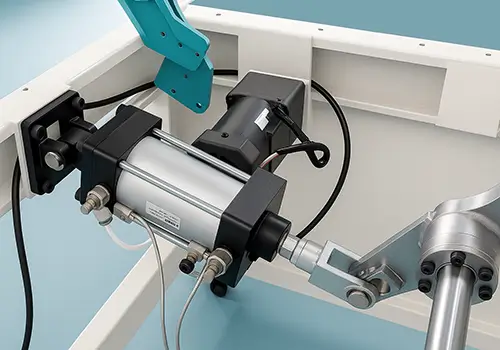

Pneumatic (cylinder-driven) operation

Max. sealing height: 11 cm (Tengyi standard)

- Sealing Speed: Up to 30pcs/ minute

Up/down linear motion by Cylinder-Driven or Servo Motor

Max. sealing height: 15 cm (Tengyi standard)

Sealing Speed:Up to 60 pieces/minute for small item

Classified by drive type, Automatic L-bar sealers can be grouped into two categories.

Pneumatic (Cylinder-Driven)

Servo Motor-Driven

Designed for high-speed operations like TY-5545CZ

Faster cutting cycle than pneumatic systems

Easier speed adjustment and control by PLC

Classified by automation, L-bar sealers can be grouped into manual, semi-automatic, and fully automatic models. Tenyig mainly focuses on the manufacturing of fully automatic L-bar sealers.

Manual L Bar Sealers

Manual L-bar sealing requires manual stretching of the shrink film to a set location, inserting the product into the folded film, and pressing down on the L-bar for sealing.

It does take some learning, as improper heating duration can cause the films to puff up and possibly puncture.

This kind l bar sealer is suitable for products that require infrequent heat sealing and come from small or occasional orders.

Semi-Automatic L Bar Sealers

Semi-automatic L-bar sealer models come with an initial and basic automation function, such as transferring a wrapped package automatically into a heat tunnel. For the most part, however, a semi-automatic L-bar sealer is not fully automatic, the speed of the seal is dependent on the operator’s speed.

Semi-automatic L-bar sealers are cost-effective and flexible, making them suitable for medium-volume packaging needs where full automation isn’t necessary.

Automatic L Bar Sealers

This kind of L bar sealing machine is made for fast packing needs, speeds over large scales.

They have product feeding, film feeding, detection, and sealing that can all be automated, requiring very little manual work beyond simply setting the temperature.

For instance, the TY- 5545CZ L-bar sealer can wrap almost 60 packs per minute.

Tengyi Automatic L Bar Sealers Collection

Comparing Three Automatic L-Bar Sealers: Find the Ideal Solution for Your Business

| Feature | TY‑5545Q (Cylinder‑Driven Vertical L‑Bar Sealer) |

TY‑5545 L‑Bar Sealing Wrapper |

TY‑5545CZ (High‑Speed Vertical Servo Sealer) |

|---|---|---|---|

| Drive Type | Pneumatic cylinder (standard, consistent) | Servo motor‑driven for high-speed control | |

| Sealing Speed | Up to ~30 pcs/min for small items | Faster cutting cycle / 40-60 pcs/min | |

| Max Sealing Height | ~150 mm | ~110 mm | ~150 mm |

| Control | PLC, touchscreen memory, parameter setting | PLC/servo, easier speed adjustment | |

| Film Handling | Supports center-fold POF, PVC, PS, PE etc. | Same as the other two, with more precise tension control | |

| Applications | Medium–high volume packaging lines | High-speed industrial use (e.g. cosmetics, pharma) | |

| Typical Industries | Retail, food, cosmetics, pharma, e‑commerce | Same as the other two, focused on speed-intensive ops | |

| Price Range | |||

Tengyi Automatic L Bar Sealer Key Features

Efficient Sealing System

Digitally controlled thermal knife for smooth and long-lasting seals

Intelligent Automation Control

PLC control with automatic operation modes Touchscreen with program memory function for quick changeover

Shrink Film Management

Shrink Film perforation and tension control to prevent wrinkling and bubbling

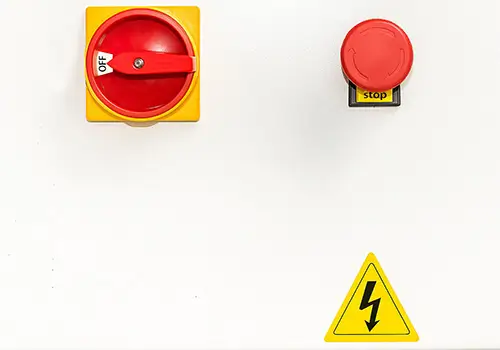

With Safety Consideration

Equipped with an emergency stop button to ensure operational safety

How an Automatic L-Bar Sealer Works

The entire sealing process is controlled by a PLC intelligent control system that adjusts the sealing temperature, sealing time, and conveyor speed, enabling unmanned, efficient, and stable automated shrink wrap packing.

Product Conveying

The products are placed on the conveyor belt, which automatically transports them to the sealing position.

Step 1

Automatic Film Feeding

The shrink wrap film is automatically fed by the L bar sealer and covers the product.

Step 2

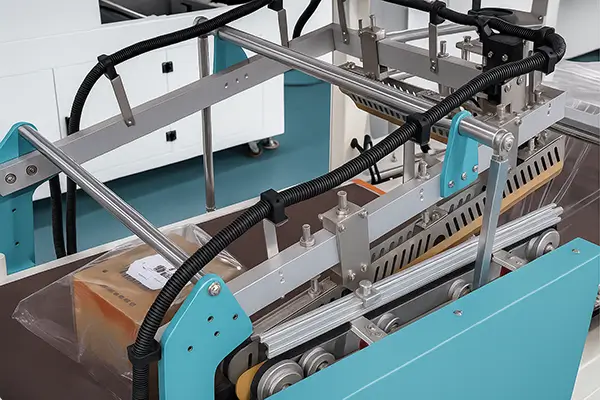

Sealing and Cutting

After the product is detected by the electronic sensor, the heated L-shaped sealing blade automatically lowers, melting and sealing the film edges while simultaneously cutting off the excess film to form a sealed package.

Step 3

Waste Film Collection

Excess film is automatically collected and rolled up to keep the workspace clean.

Finished Product Output

The sealed product is automatically conveyed out of the machine. Some L-bar sealers integrate with a heat-shrink tunnel for subsequent shrink packaging.

The Role and Importance of L-Bar Sealers

L-bar sealers are mostly secondary packaging machines in today’s packaging operation. These machines in the packaging process are used after the primary packaging (which typically, but does not need to be, cartons, plastic bottles, or cans) has been completed.

- Sealing and Wrapping of Products: Automatically feeds, seals, and cuts shrink film for quickly and efficiently wrapping pre-packaged products.

- Creating “L” Shaped Seals: Sealing one product side and end and the next product front edge takes place simultaneously.

By enclosing items with shrink film, L-bar sealers improve the overall appearance, protect the items from damage while being stored and transported, and provide additional protection from tampering or removal of items.

What Benefits Can L-Bar Sealers Bring to Your Business?

Improve Secondary Packaging Efficiency

Integrated with primary packaging lines,Tengyi L-bar sealers execute shrink wrapping in a single motion(Scissor-Type or Vretical Type)—ideal for high-volume production.

Versatile Packaging Applications

Suitable for plastic bottles, cartons, irregular shapes, and bundled products. Compatible with various gauge center folded POF films.

High-Quality and Precise Seals

Teflon-coated sealing blades ensure consistent, clean, and strong seals that enhance the appearance and durability of packaging.

Enhance Product Protection & Brand Image

Provides tamper-evident, dust- and moisture-resistant wrapping while delivering a clean, professional look that strengthens shelf appeal.

Looking for a Custom L-Bar Sealer Solution?

As a professional L-Bar Sealer manufacturer, we specialize in tailor-made solutions to fit your packaging needs. Whether you’re handling bottles, boxes, or irregular shapes, we build L bar sealers that match your production line perfectly.

Why Choose Tengyi as Your L Bar Sealer Supplier?

Leveraging more than 10 years of experience across different industries, we deliver meticulously tailored L-bar sealer with heat tunnel solutions designed for your unique sector’s needs.

Hassle-Free After-Sale Service

Supply of Spare Parts.

Tengyi will provide L Bar sealer spare parts, like sealing blade, Silicon pads, and support on a cost-price basis.

Repair/Modification Plan Assistance

A Repair/Modification Plan for the L bar Sealer will be provided to help support you with repairs.

If you carry out repairs on-site overseas and this involves the support of engineers from Tengyi, you will pay for the visa, airfare, hotel accommodation, and labor costs.

Technical Training

Video materials will be supplied for training (for use in installation, debugging, etc).

If you would like to have training on-site overseas, you will pay for the visa, airfare, hotel accommodation, and labor costs for the Tengyi engineers.

Remote diagnosis and troubleshooting

We will provide a video explanation, etc., to help support the customer in getting used to the Tengyi L bar Sealers to help solve problems you are having using the automatic L bar sealing machine from Tengyi

Our ultimate goal is to ensure the Automatic L bar sealer is stable, user-friendly, and durable, which helps your business.

Widely Applicable Across Various Industries

- Cosmetics Industry

- Household chemicals

- Pharmaceuticals

- Consumer Goods like electronics

- E-commerce & Mail Packages

In addition to L-bar sealers, you may also need side sealers, sleeve wrappers, and heat tunnels.

You can explore all these options at the automatic shrink wrap machine page.

FAQs Regarding Tengyi L Bar Sealers

What type of shrink film is typically used with an L-bar sealer?

L-bar sealers are made to work with center-fold shrink film and are ideal specifically for Polyolefin (POF), PVC, and Polyethlyene (PE) films.

Polyolefin is typically recommended when packaging retail and food packaging because of its clarity and strength, it gives a professional look to the products and provides reliable protection.

Are your L-Bar Sealers designed for industrial use?

Yes, our Automatic L-Bar Sealers, along with a shrink tunnel, are designed for use in the industrial environment.

They have high cycle speeds; the ty5545l wraps approximately 30 parts per minute, meaning you could quickly add them onto an automated production line and have the completed wrapped parts quickly and consistently.

Note that they are very large machines (TY-5545L is approx. 2 meters long, 1.2 meters wide, 1.75 meters height) and therefore require suitable dedicated space for optimal setup and operation.

What should I consider when buying an L-bar sealer?

Choosing the right L-bar sealer depends on your packaging needs, workspace, and plans. Here are 5 key factors to think about.

- Package volume: If you are sealing less than 50 packages in a day, a manual L-bar sealer should work.

For about 150 packages a day, a semi-automatic machine is a nice compromise of speed and efficiency.

And if you are packaging more than 1,000 packages daily, a fully automatic L-bar sealer like TY-5545L saves you time and labor. - Product Size & Shape: L-bar sealers are great for shrink-wrapping a variety of product shapes, like bottles, boxes, and more—just not round or spherical items.

As long as your product fits within the machine’s sealing limits for length and width, it should work just fine. For example, with our TY-5545 L bar sealer, the product height should be under 10 cm for easy pass-through.

If you’re not sure whether your product is a good fit, just reach out to our expert—we’re happy to help! - Product Weight For heavier items over 3 kg—like metal parts or bottled liquids—choose a l bar sealer with a strong sealing system and a heavy-duty conveyor (e.g., with stainless steel rods).Lighter products like snacks or paper goods work well with standard mesh belt conveyors.

Available space If you’re using it at home, it’s best to go with a compact tabletop manual sealer—it takes up less space and is easy to store.

TENGYI mainly produces fully automatic L-bar sealers designed for industrial use. Most of these machines are over 1.8 meters long and 1 meter wide, so you’ll need enough space to set them up.- Budget & Future Growth Think about your current budget and how your business might grow.Example:If you’re starting small but expect to scale up, consider a semi-automatic machine that allows future upgrades—like adding an automatic feeding system or shrink tunnel—so you won’t need to buy a new machine later.

What kind of maintenance does an Automaic L-bar sealer require?

Performing appropriate maintenance on your L-bar sealer will keep your machine running smoothly and extend its life. Below is a basic maintenance schedule

Daily

Regularly clean the machine to remove dust and film build-up.

Monthly

- Check the wear on the Teflon tape and silicone strips on the blade and pressure bar.

- Tighten the sealing bar screws as necessary.

Every 3 Months

- Grease the chain.

- Oil bearings and bearing housing with hydraulic oil.