Industrial Automatic Sleeve Wrapper Machines & Shrink Bundlers

High-Stability Bundling Solutions for Bottles, Cans, and Cartons

Engineered with Mitsubishi PLC Control and Servo-Driven Motion for 24/7 Continuous Production.

Packaging at the end of the line needs to be steady rather than flashy. When this stage struggles, everything behind it slows down. Tengyi sleeve wrapping and shrink bundling machines are built with that reality in mind. They are meant to run consistently, hold bundles together properly, and stay reliable across long production days.

Performance at a Glance

Output that stays consistent

Most systems operate anywhere from 8 to over 20 packs per minute. Actual speed depends on how products are grouped and how the machine is set up, but the priority is steady movement rather than chasing maximum speed.

Industry-Standard PLC Integration

PLC systems, such as those from Mitsubishi and Panasonic, are commonly used because they are reliable and easy for maintenance teams to support over time.

Layouts that work with existing lines

Sleeve wrapping machine can be arranged to feed straight through or from the side, making it easier to fit into your current conveyor setups.

Built for long operating hours

Frames, drives, and sealing parts are designed for repeated use across full shifts, not short runs or controlled demos.

Making End-of-Line Packaging Easier to Manage

Sleeve wrapping is often chosen when operations want to simplify how products are grouped before storage or shipping. It offers a practical alternative to boxed packaging, helping reduce material handling while still keeping products secure as they move through warehouses and distribution centers.

Tengyi designs its systems to support this part of the process without adding complexity. The goal is clean bundles, consistent sealing, and fewer interruptions once the machine is running.

Designed with Uptime in Mind

In real production environments, small stops add up quickly. That’s why these machines are built around proven components and straightforward layouts. Instead of relying on complex mechanisms, the focus stays on stability and repeatable performance.

Each system can be adjusted to match the space available and the pace of the line. Rather than forcing operations to adapt to the machine, the machine is set up to support how the line already works, helping keep output steady and predictable over time.

Manufacturer Overview

- Manufacturing facility: approximately 2,500 m²

- Engineering team: 6 dedicated R&D engineers

- Typical monthly output: around 30 shrink bunlding machines

Tengyi equipment is currently used across 30+ industries worldwide, supporting a wide range of secondary packaging requirements.

Tengyi Sleeve Wrapping Machine Series Overview

Tengyi offers multiple sleeve wrapping machine models to match different production volumes, automation needs, and line integration requirements. Model selection is typically based on output targets, product type, and available floor space.

Fully Automatic Sleeve Wrapping Machine-TY-800A

Automation level: Fully automatic

Typical output: Approximately 5–8 bundles per minute (including automatic collation)

Typical applications

Medium to large manufacturers are reducing manual handling

Operations with relatively stable product formats

System characteristics

- Integrated automatic grouping unit

- No manual stacking during normal operation

- Supports common layouts such as 2×3 and 3×4

- Suitable for bottles and cartons

- Often selected when upgrading from semi-automatic systems

Semi-Automatic Sleeve Wrapping Machine-TY-P500

Automation level: Semi-automatic

Typical output: Approximately 8–10 packs per minute

Typical applications

- Contract packers and craft beverage producers

- Facilities with frequent format changes or short production runs

System characteristics

- Manual product loading

- Button-controlled sealing and cutting cycle

- Optional photoelectric sensing upgrade

- Lower initial investment compared with fully automatic systems

- High flexibility for mixed or changing pack formats

High-Capacity-Inline-Shrink-Bundler-DLL-450A

Automation level: Fully automatic, inline

Typical output: Up to approximately 20–30 packs per minute

- Large-scale beverage lines with continuous operation

- Standardized containers such as water, soft drinks, and beer bottles

- Inline integration with automatic lane dividing

- Servo-driven motion for continuous operation

- Covers conveying, alignment, grouping, wrapping, shrinking, cooling, and downstream transfer

- Designed for high-throughput end-of-line environments

*Actual output depends on product size, pack layout, film type, and line configuration.

Why Choose Tengyi – Technical Advantages

Engineering Choices That Support Reliable Operation

Tengyi designs sleeve wrapping systems for continuous industrial use.

The focus is on precision, durability, and long-term stability.

Each core component is selected to reduce downtime and maintenance risk.

Precision Sealing and Cutting

Tengyi machines use Teflon-coated alloy sealing knives. Sealing and cutting are completed in a single, continuous movement, which helps maintain consistent seal quality with PE and PVC shrink films.

Technical characteristics

- Reduced smoke during operation

- Minimal film adhesion to the sealing blade

- Avoids common issues associated with thin hot-wire sealing bars

Operational impact

- Cleaner seals with fewer interruptions

- Lower routine cleaning requirements

- Secure bundles during handling and transport

Servo-Driven Stability vs. Pneumatic Systems

| Feature | Servo Systems | Pneumatic Systems |

|---|---|---|

| Motion Behavior | Runs smoothly with continuous movement. | Operates in start-stop cycles. |

| Operating Speed | ~15 packs per minute (layout-dependent). | 5–8 packs per minute (typical range). |

| Positioning Accuracy | High precision: approximately 0.1 mm. | 2–3 mm (influenced by air pressure stability). |

| Maintenance | Requires less routine maintenance; no air compressor needed. | Relies on compressed air and components prone to wear. |

| Energy & Long-term Cost | Higher energy efficiency; lower long-term operational costs. | Involves ongoing compressed air and compressor upkeep costs. |

| Inspection Schedule | Recommended at least twice per year. | Recommended at least twice per year. |

Summary: Servo-driven sleeve shrink bundling systems support smoother conveying, more consistent sealing, and reduced mechanical stress. Over time, this can lower wear rates and total ownership cost.

Global Control and Automation Components

Key control and automation components are sourced from established international suppliers commonly used in industrial machinery.

PLC controllers

Mitsubishi, Panasonic, Inovance

Electrical components

Schneider Electric

Sensors and switches

Omron

Pneumatic components

Airtac

Component brands can be specified based on customer preference, budget, and local service availability. This supports compatibility, serviceability, and long-term operational stability.

Typical Applications and Operational Considerations

Tengyi sleeve wrapping systems are used across a wide range of industrial packaging environments. They are often selected to reduce secondary packaging material use, improve bundle stability, and increase end-of-line efficiency.

Industries and applications

Beverages and bottled water

PET bottles, glass bottles, aluminum cans, juice cartons, with or without trays

Food and dairy

Canned food, Tetra Pak cartons, yogurt cups, condiment bottles

Logistics and e-commerce

Cartons and bulk items for warehouse distribution

Systems are designed to handle wet or condensation-prone containers and operate reliably in production environments.

Cost and Packaging Considerations

Material cost comparison (indicative, per 1,000 units)

- Corrugated cartons: USD 300–400

- PE film sleeves: USD 80–120

In suitable applications, this can represent a 60–70% reduction in secondary packaging material cost.

Additional considerations

- Reduced bundle weight lowers transport costs

- Film rolls require less storage space than cartons

- Shrink film provides visible tamper evidence

- PE film offers better moisture resistance than corrugated board

- Printed film can carry branding and regulatory information

The ROI varies depending on product size, packaging format, production volume, and local costs.

You can enter your actual data in the form on the right to calculate your personalized ROI.

Enter your numbers below to see your immediate ROI:

Your Instant Results:

Automation Level Comparison

| Feature | Semi-Automatic (TY-P500) |

Fully Automatic (TY-800A) |

High-Speed Inline (DLL-450A) |

|---|---|---|---|

| Loading | Manual | Automatic infeed | Inline integration |

| Grouping | Manual | Automatic | Lane divider |

| Speed | 8–10 packs/min | 5–8 bundles/min* | 20–30+ packs/min |

| Labor | 1–2 operators | Minimal | Supervised operation |

| Investment | USD 20k–40k | USD 60k–80k | USD 150k–200k |

| Flexibility | High | Medium | Low |

*Speed includes automatic collation time.

Learn more? Take a look at our clear, simple comparison. →

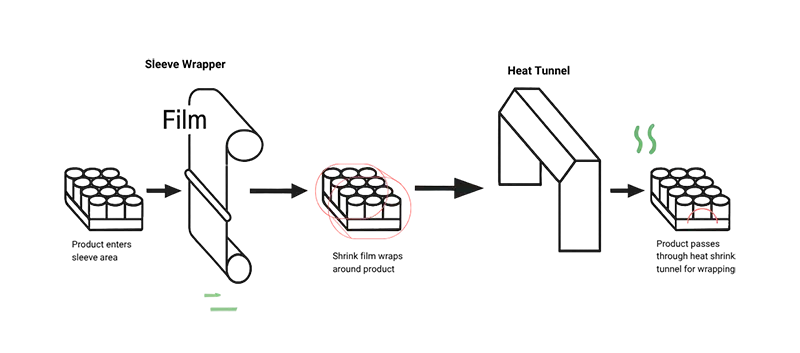

How a Sleeve Wrapping System Operates

Infeed and collation

Products enter via conveyor. Automatic models use guides and sensors to form defined patterns.

Step 1

Film draping

Two film rolls drape over the product flow to form a loose sleeve.

Step 2

Sealing and cutting

A heated alloy blade cuts and seals in one motion, supporting continuous operation.

Step 3

Shrinking and cooling

Controlled heat activates shrink, followed by cooling to stabilize bundles for stacking and transport.

Success Stories of Tengyi Machine’s Sleeve Shrink Machines

Protect Cartons: Tengyi Sleeve Shrink Wrapper for Boxes & More!

The Cost-Saving Secret for Beverage Factories

Information Hub: Shrink Bundler Solutions

Frequently Asked Questions

What's Sleeve Wrapper?

A sleeve wrapper is a packing machine that wraps several items together into one unit (for shipping or selling) using a sleeve of plastic film (such as PE or PVC). Sleeve wrappers typically have two rolls of film (top and bottom), and in the end, provide a secured and protected package.

What differentiates a sleeve wrapper from a bundle wrapper?

The terms “sleeve wrapper” and “bundle wrapper” are often confused. Both generally refer to a machine that groups several pieces of product with a thin, plastic film sleeve for handling and distributing or protecting.

What is the difference between sleeve wrapping and full shrink wrapping?

Sleeve wrapping leaves open ends, using less film and allowing airflow. Full wrap seals all sides.

What is a sleeve wrapping machine used for?

It bundles products using PE or PVC shrink film sleeves, commonly for bottles, cans, and cartons.

What are the main benefits of using a sleeve wrapper?

Key benefits include:

Integrated Film Wrapping, shrinking

Secure, tamper-evident packaging

Versatile product compatibility

Reduced cardboard waste and cost

Is a shrink tunnel required?

Yes, in most applications, a heat shrink tunnel completes the process.

What production speeds are typical?

- Semi-automatic: 8–10 packs/min

- Fully automatic: 5–8 bundles/min

- High-speed inline: 20+ packs/min

What types of film are compatible with sleeve wrappers?

What is a “bullseye” in sleeve wrapping and how can its size be adjusted?

A bullseye refers to the open ends on the sides of the shrink-wrapped bundle. The size can be adjusted by changing the film width:

Wider film = smaller bullseye

Narrower film = larger bullseye

Do you provide installation and support?

Remote guidance, documentation, and optional on-site support are available.

Can machines be customized?

Yes. Layout, dimensions, and configuration can be adapted based on application needs.

Request Technical Evaluation and Quotation

If you are reviewing sleeve wrapping options for your line, please share your product dimensions, pack format, and output targets. Our engineering team can:

- Recommend suitable machine configurations

- Provide layout references

- Estimate cost and ROI

In addition to shrink bunddler, , you may also need L bar sealer, side sealers, and heat tunnels.

You can explore all these options at the automatic shrink wrap machine page.