Case Erector

The Tengyi TY-K200 automatic case erector is an extremely effective assistant for your plant. It automatically processes flat cardboard, unfolds it into a precisely square box, and even folds and seals with tape the bottom flaps.

It’s all about making things simpler: significantly accelerating your carton erecting procedure and eliminating manual tasks. Ultimately, it boosts your profits and enhances your competitiveness.

TENGYI TY-K200 Automatic Case Erector: Intelligent, Efficient, and Stable Packaging Solution

The TY-K200 is the ultimate efficient solution for taking flat cardboard to properly erected cartons.

✓ Fully Automatic Case Erecting:

Significantly reduces labor costs and improves production efficiency.

✓ Stable and Reliable Performance:

With years of development and market validation, the Tenyi KY-200 case erector is a proven, stable, and easy-to-use case erector. It reliably produces perfectly square and sturdy cartons, every single time.

✓ Flexibility:

For quick changeover between carton sizes and styles.

✓ Easy Integration:

Integrates with your existing packaging production lines, such as case sealers, and case packers, to improve packaging efficiency.

TY-K200 Automatic Carton Erector: The Beginning for Packaging Automation

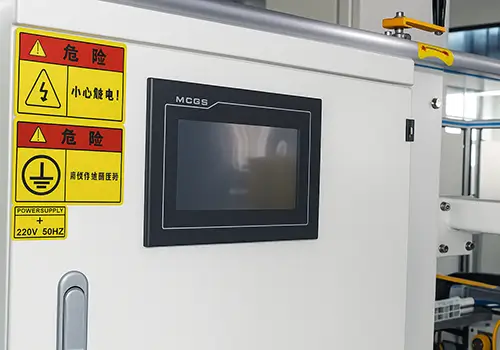

Smart Control Panel

Featuring an intuitive interface, this system integrates all essential controls—power, start, pre-stop, temperature, conveyor speed, and emergency stop—for effortless operation and precise process control.

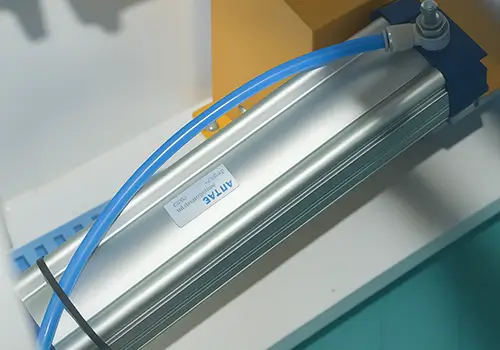

Pneumatically Driven

The K200 case erector uses 3 cylinders drive for great, reliable performance with low noise and smooth machine operation. The case forming speed can be adjusted by varying the air volume.

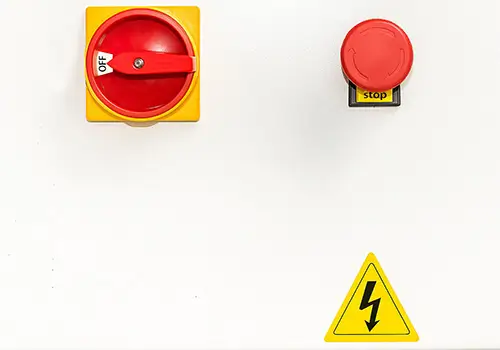

Multiple Safety Guarantees

TY-K200 Equipped with safety devices such as an emergency stop button and safety door interlocks, It also automatically alarms when there's a shortage of cartons, ensuring smooth and safe operation.

Built to Last: Cold-Rolled Steel Chassis

Built for longevity, the case erector's core structure utilizes cold-rolled steel, providing unparalleled strength and stable operation through years of use.

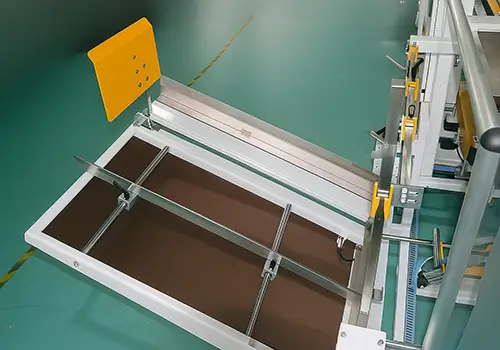

Durable Conveyor Belt

High-quality PVC conveyor belt, durable enough for frequent use.

Efficient Cable Management

This cylinder-driven cable carrier system, crucial for carton erectors, efficiently protects and guides essential cables and hoses, ensuring reliable machine operation.

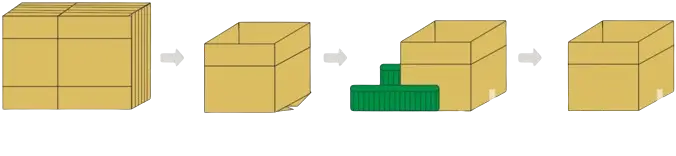

How It Works

The TY-K200 takes flat cardboard, transforms it into an open box, folds the bottom flaps, and seals it with tape—leaving it ready to be filled.

Feed Cardboard

Flat sheets of cardboard will be provided in the whole folder. The sheets will be taken by suction cups.

Step 1

Automatic Box Forming

A robotic arm will pick up the cardboard and carefully unfold it into a 3-D box/ carton.

Step 2

Carton Bottom Folder/ closer

The bottom flaps of the box will be automatically folded inward and quickly and securely sealed by adhevie tape applicator.

Step 3

Box Output for Subsequent Processing

The cartons will then be sent to the next step in the process and be filled with the appropriate contents.

Technical Specifications

| Parameter | TY-K200 Case Erector |

|---|---|

| Box Size Range | 80≤L≤500mm, 160≤W≤400mm, 510≤L+W≤1000mm, 300≤H+W/2≤620mm,Customizable |

| Case Forming Speed | 8 -10 boxes per minute (varies by box size) |

| Power Supply | 220V or 380V, 50Hz, Adjustable |

| Power Consumption | 0.4 kW |

| Air Pressure | 0.6 MPa |

| Air Consumption | 450 NL/min |

| Machine Dimensions | 2050mm (L) x 1950mm (W) x 1450mm (H) |

| Machine Weight | Approximately 400 kg |

| Tape Width | 48mm, 60mm, or 75mm BOPP Carton Sealing Tape |

| Working Height | 650mm |

Select the Tengyi TY-K200 to provide real benefits to your company.

Substantially reduce labor costs:

It just requires one worker to operate the equipment, for example, to load unopened cartons. The carton erector will perform the unpacking (erection) and bottom sealing.

One machine can provide the labor of 3-5 manual workers on a per-unit time basis, greatly reducing labor costs and increasing return on investment.

Considerably increase production efficiency:

It is capable of automation and continuous operation and can yield a packaging line when combined with case packers, case sealers, strapping machines, etc., running at higher speeds of production to address high-volume orders in back-end packaging applications.

Improve packaging quality and consistency:

With a precision machine operation, it consistently forms each box square, consistently and aesthetically pleasing which enhances the product's brand image with customers.

Decrease adhesive tape waste:

Compared to manual bottom sealing, the carton erector reduces the costs of inconsistent material consumption:

Manual operations can lead to excessive non-consistent tape usage causing increased consumable costs.

The carton erector TY-K200 automation of erecting and bottom sealing ensures consistency in tape application which reduces costs associated with this area.

Enhance the working environment:

Reducing repetitive manual lifting lessens the burden on workers, enhances the employee work experience, and improves packaging safety.

Tailored Designs for Your Unique Packing Needs

Need Custom Carton Erector Solutions?

Contact Tengyi Machine today for tailored case erector designs and manufacturing that meet your unique carton size, and production environment needs.

Widely Applicable Across Various Industries

- Food and Beverage Industry

- Cosmetics Industry

- Household chemicals

- Pharmaceuticals

- Consumer Goods like electronics

- E-commerce & Mail Packages

FAQs Regarding Tengyi Case Erector

What's Case Erector?

A carton erector (which may be referred to as a case erector, box forming machine, or carton forming equipment) is a machine that automatically forms flat corrugated cardboard blanks into a box and seals the bottom flaps.

Each machine is built for efficiency in the packaging process to prepare boxes for product filling and sealing.

Choosing Your Carton Erector: Tape or Hot-Melt Glue?

Carton erectors usually seal the bottom of the box using adhesive tape or hot melt glue. The TY-K200, for example, uses adhesive tape to seal the bottom flaps.

When comparing the two, hot melt glue will usually create a stronger seal and would be preferred for heavier merchandise like bottled water cartons. Adhesive tape generally is better for lighter-weight products like 3C electronics products or small e-commerce packages.

For carton erectors that use adhesive tape, the erector uses an adhesive tape applicator to seal the bottom flaps and form the carton.

Hot melt glue erectors have a separate component known as the glue applicator that heats, melts, and applies the glue to the bottom of the box to seal the flaps.

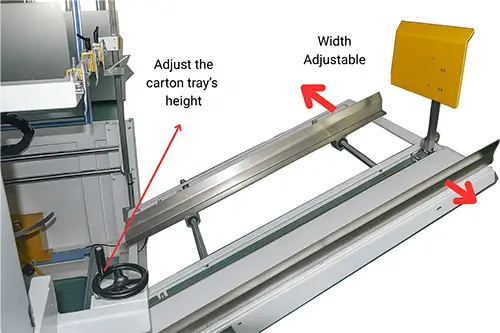

How do carton erectors adapt to different box sizes and types?

Most carton erectors can handle various box sizes by manually adjusting the width and height of the carton feeding mechanism, as shown in the image above

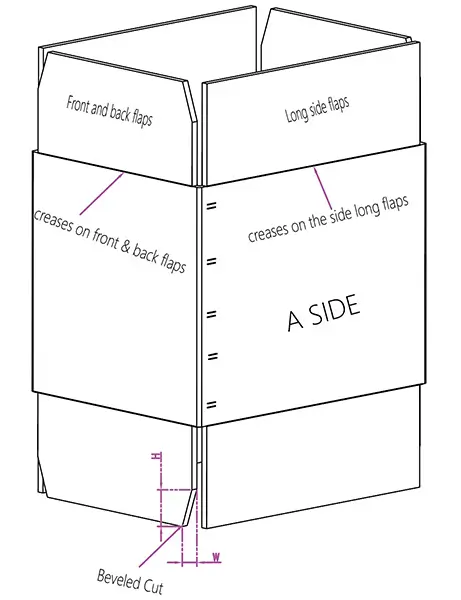

What's the carton requirements for TY-K200 case erectors?

Creases: Must be deepper for 5+ layer cartons; side flap creases ideally higher than front/back.

Cardboard: Should be flat and not too soft, especially for high-speed case erectors. Samples of cartons 5 layers thick or more are required for Tengyi to evaluate their fitness for use with the carton erector

Beveled Cuts: Essential for all cartons, especially 5+ layer and high-speed required, to prevent jamming. Dimensions: ~1/3 front/back flap height, width ~4x carton thickness.

Flaps: Side and front/back flaps must not overlap when flat (1-2mm gap for sides). Square boxes need beveled cuts for good forming.

Dimensions: Complete carton specifications are required for Tengyi's assessment.

Please be aware that a single case erector mechanism may not accommodate cartons with widely disparate proportions (e.g., both very large and very small).

What are the after-sales support services for the case erector provided to overseas customers?

In terms of after-sales support for overseas customers, Tengyi undertakes to provide the following:

- Supply of Spare Parts. Tengyi will provide case erector spare parts support on a cost-price basis.

- Repair/Modification Plan Assistance: A Repair/Modification Plan of case erector will be provided to help support you with repairs. If you carry out repairs on-site overseas and this involves the support of engineer from Tengyi, you will pay for the visa, airfare, hotel accommodation, and labor costs.

- Technical Training: Video materials will be supplied for training (for use in installation, debugging, etc). If you would like to have training on-site oversea, you will pay for the visa, airfare, hotel accommodation, and labor costs for the Tengyi engineers.

- Remote diagnosis and troubleshooting: We will provide a video explanation, etc., to help support the customer in getting used to the equipment or to describe problems they are having using the case erector.

Our ultimate goal is to ensure the case erector is stable, user-friendly and durable, which helps your business.

Customer Testimonials: Tengyi Case Erector Boosts Your Productivity

Client: A Consumer Electronics Company

Challenge: Before 2018, this client was completing all packaging with manual case erecting, which took time and was expensive.

Solution: They decided to invest in the TY-K200 automatic case erector, automating the case-forming process.

Results: They achieved a 30% increase in packing efficiencies, saved 2-3 manual laborers, and regulated and standardized carton formation.

“The TY-K200 has streamlined our packaging process, achieving true staff reductions and efficiencies!“

Client: An E-commerce Logistics Hub

Challenge: Managing tens of thousands of packages every day and the need for extremely high speed for carton supply and stability for sealing, packing

Solution: They installed many packaging lines that included the TY-K200 case erector, case packer, and case sealer with a package system that built highly effective carton supply and packaging speed.

Results: One line alone increased carton supply and packaging speed by more than 10x, allowing continuous workflow, and relied on only a tenth of the human oversight per packaging line which subsequently increased shipping capacity during peak season and decreased fatigue and mistakes from a manual operation.

“The package lines from Tengyi are unbelievably quick and stable, allowing us to easily handle major promotions like ‘Double Eleven’ (Singles’ Day)!“