Heat Shrink Tunnels

The shrink tunnel is central to a great shrink wrap machine combo, and at Tengyi, we’ve dedicated over 10 years to perfecting its production. As experienced manufacturers of heat shrink tunnel equipment, our passion is building high-quality, high-performance tunnels designed to fit seamlessly into diverse industries and expertly handle all your unique shrink wrap packaging needs. We make sure our tunnels work for you.

CLASSIFICATION

Main Types of Shrink Heat Tunnels

So, what kind of shrink tunnels are out there? You’ve heard of hot air, steam, and even infrared heating ovens.

As for us, we mainly build two kinds, depending on how they generate heat.

Hot Air Shrink Tunnels

Primarily use heated air as the heat transfer medium, circulating hot air to shrink film

Steam Shrink Tunnels

Transfer heat by injecting steam into the tunnel, shrinking film. Ideal for heat-sensitive products

Electric or Steam? Shrink Tunnel Comparison at a Glance

| Feature | Electric Heat Shrink Tunnel/Hot Air Tunnel | Steam Shrink Tunnel |

|---|---|---|

| Output Speed | Max 100 pcs/min | 100–150 pcs/min |

| Temperature | 110–180°C | 90–100°C |

| Applicable Film | POF, PE, PVC, OPS | PETG, PVC, OPS etc. |

| Shrink Effect | Good | Excellent |

| Energy Consumption | Lower (~15 kg/h) | High (27–30 kW/h) |

| Maintenance | Low maintenance compared to steam tunnels | Requires at least daily water drainage |

| Application Scope |

Suitable for moisture-sensitive products such as dry food, biscuits, and tea. Ideal for small-batch packaging lines. Used in industrial goods like tapes and electrical materials. |

Designed for high-output lines and bulk production with strict packaging quality. Best for liquid product labeling (e.g., beverages, wine). Excellent for PETG and special label shrinking. Handles irregular-shaped containers. Suitable for moisture-resistant products. |

| Equipment Cost | USD 1100–3600 depending on configuration | Approx. USD 4500 for standard TY-W300 model |

For more differences between steam vs hot air tunnels, visit this post steam heat tunnel vs hot air tunnel

Featured Heat Shink Tunnels

5030 ConstantTemp Shrink Tunnel

Equipped with 9 stainless steel heating tubes, each rated at 1,800W, as the heat source. Upto 180°C

Shrink Wrap Tunnel TY-4525B

Features 12 stainless steel heating tubes, each rated at 900W, as the heat source, upto 150°C

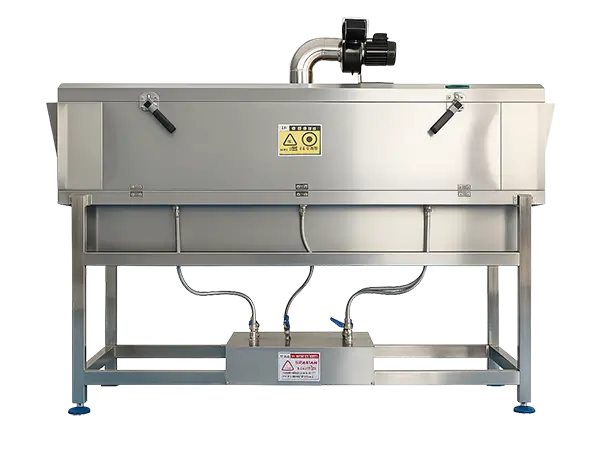

Steam Shrink Tunnel TY-W300

Heat tunnel for shrink sleeves of labels, providing gentle, uniform temperatures (93°C-100°C).

TENGYI Shrink Heat Tunnels: Versatile, Customizable, Safe

Temperature Versatility

For POF film, 130-150°C is usually sufficient. Our hot air shrink tunnel is also compatible with all other film types, capable of reaching up to 180°C (356°F) for broader applications.

Customizable

Conveyor Speed: Standard 20m/minute; customizable to your production pace.

Tunnel Size: Customizable dimensions to fit all product sizes.

Conveyor Material Options: Choose between Teflon Mesh Belt (for lighter/irregular items) or Stainless Steel Roller Conveyor (for heavier/larger items).

Auto-Shutdown Safety

TENGYI hot air shrink tunnels auto-shut down if temperatures exceed set by 5°C, preventing fire hazards for secure operation.

Shrink Tunnel Showdown: TY4525 vs. TY5030 for Optimal Performance

| Feature | 4525 Constant Temperature Shrink Tunnel | 5030 Constant Temperature Shrink Tunnel |

|---|---|---|

| Heat Source Location | Left and right sides, motor at top for top-down airflow | Bottom of the machine for bottom-up heat distribution |

| Operation Mode | Top-down airflow, fixed wind speed and direction | Bottom-up airflow, adjustable direction (left/right) and wind speed/volume |

| Air Circulation Fan | Turbine-style fan blades, non-adjustable speed | Turbine-style fan blades, adjustable speed |

| Airflow Adjustability | Fixed air vents, no fine-tuning | Fully adjustable airflow direction |

| Efficiency | 1,000–1,200 units/hour | 1,500–2,000 units/hour |

| Thermal Insulation Experience | Noticeably warm, may exceed 40°C | 10 cm thick insulation cotton, double-layer design, mild perceived temperature |

| Packaging Performance | Slightly inferior shrink effect compared to 5030 (same product/film) | Superior shrink effect compared to 4525 (same product/film) |

| Product Compatibility | Max height: 230 mm, max width: 430 mm | Max height: 280 mm, max width: 480 mm, adjustable to requirements |

| Visualization | Non-visualizable (air vents on side panels) | Visualizable (bottom airflow allows side panel windows) |

| Configuration | Huibang (domestic) temperature controller, 750 kW air circulation motor | Dual Schneider frequency converters, Omron temperature controller, 1,500 kW air circulation motor |

Core Controllers for Hot Air Shrink Tunnels

-

Temperature Controller:

Precisely regulates chamber temperature, maintaining it within ±1–2°C of the set point (e.g., 130°C), ensuring consistent operation and optimal shrink performance. e.g The TY-5030 is equipped with Omron Temperature Sensor

-

Conveyor Speed:

The TENGYI hot air shrink heat tunnel's conveyor typically runs at 20 meters per minute, which works great for most items. But don't worry, if your products need a different pace, we can customize for you!

Why Choose Tengyi Heat Shrink Tunnels

High Quality and Durability

Our Shink tunnels are constructed with heavy-duty steel bodies, welded tubular steel frames, and bases, ensuring long-term durability.

Flexibility and Adaptability

Our heat tunnels seamlessly integrate into existing packaging lines with various sealing warpers

Superior Energy Efficiency

By utilizing heat recovery technology, our tunnels efficiently reuse internal heat, maximizing thermal efficiency and minimizing energy waste.

Widely Used Across Various Industries

Home and Personal Care Industry

Product Types : Shampoo, Body Wash, Cosmetics, Cleaning Products

Recommended Solutions:

Premium Cosmetics → Steam Tunnel TY-W300(for superior packaging quality)

Regular Cleaning Products → Electric Heating Tunnel(TY-5030, 4525) (cost-effective and practical)

Industrial Manufacturing Sector

Product Types: Electrical Tape, Sealants, Tool Packaging, Hardware Accessories

Recommended Solutions:

Tape Products → Electric Hot Air Heating Tunnel TY-5030,4525 (for fast drying)

Packaging Machine Importers/Distributors: Partner with us to provide top-tier shrink heat tunnels. Seek mutually rewarding, long-term market growth? Complete the form below