A China-based manufacturer with over 11 years of experience, Tengyi excels in producing customized shrink-sleeve label applicators that ensure packing stability and accuracy.

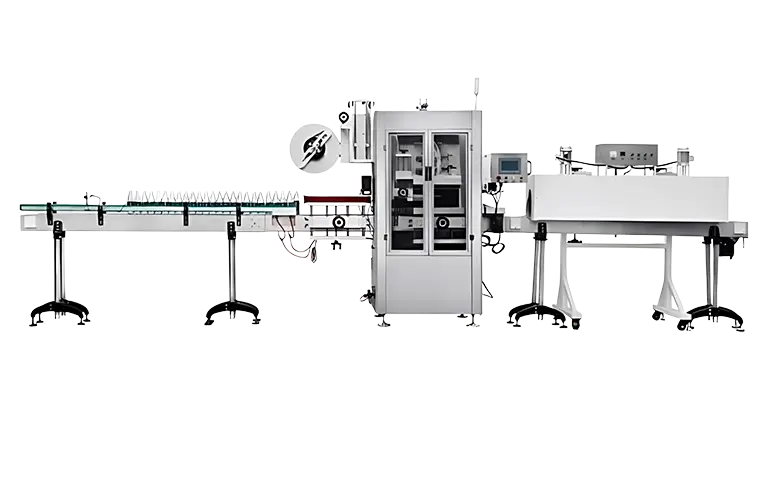

Shrink sleeve labeling machines, otherwise referred to as shrink sleeve applicators, are of critical application in all industries that include an infeed conveyor belt, sleeve applicator, and steamed heat tunnel.

These machines automatically apply shrink labels to a wide range of can- and bottle-packed goods, such as bottled water, shampoo, cosmetics, foodstuffs, pharmaceutical products, and industrial goods

After going through the steam-heated tunnel, They are becoming prominent in meeting 360-degree labeling, branding, tamper-evidencing, and meeting regulatory requirements.

Our proficiency positions us as the perfect partner for buyers, wholesalers, distributors as well as importers seeking high-performance and reliable shrink-labeling machines.

Features of TY-P150 Shrink Sleeve Labeling Machine

Improve Secondary Packaging Efficienc

Applies labels to square or round bottles at speeds up to 50-100 bottles/min. Offers quick adjustment and wide applicability for various product specifications.

Precision & Quality

Achieves high labeling accuracy of ±1mm. Features a product gripping belt and dual-pressure roller label dispensing to enhance precision and produce wrinkle-free labels, ensuring high labeling quality

Reliable Performance

Utilizes servo motor drive with true closed-loop control for high-precision positioning. Key electrical components are imported from world-renowned brands, including Japanese Mitsubishi PLC and Japanese Panasonic servo motors/sensors, ensuring lasting stability and reliability

User-Friendly Operation

Features an intuitive HMI with parameter storage/recall and guided troubleshooting. The label head's eight-dimensional adjustment allows setting up for any product in minutes

Expandability

Options available for online printing and visual inspection/rejection mechanisms. Personalized non-standard designs can be create

Robust & Hygienic Construction

Entirely built with stainless steel and aluminum alloy materials. Components are CNC-machined for high-precision fitting, smooth running, and low noise. Durable mechanical parts like wear-resistant PU rubber rollers and long-life Panasonic spiral bevel gears

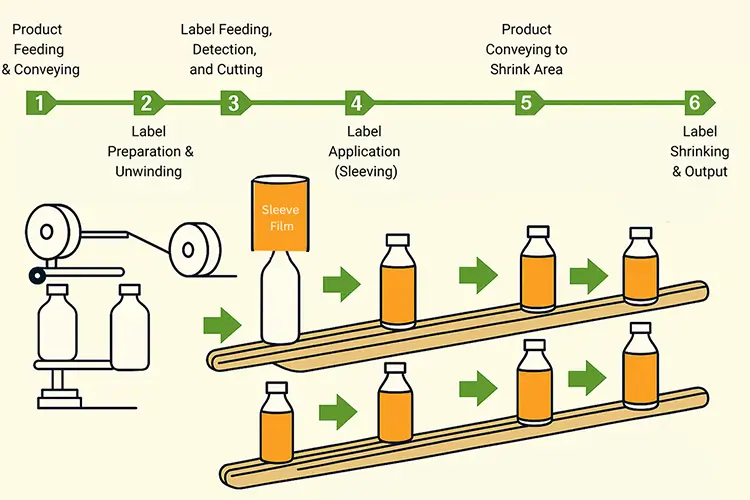

How Does The Shrink Sleeve Labeling Machine Work

Product Conveying

Products are transported into the labeling machine area, usually by a conveyor belt. For high-speed systems, this can involve product separation or gripping.

Step 1

Label Application (Sleeving)

Labels are prepared by unwinding from a roll on a stand. The label is then fed, detected by sensors, cut, and applied or “sleeved” onto the product container.

Step 2

Label Shrinking

Products with the applied label sleeve are conveyed into a shrink tunnel or oven. Inside the tunnel, heat (such as hot air or steam) is applied, causing the label to shrink tightly around the product, conforming to its shape.

Step 3

Finished Product Output

The products with the fully shrunk labels are then discharged from the shrink tunnel as finished items.

What types of bottles can the Tengyi shrink sleeve labeling machine TY-P150 handle? Below is the parameter table for your reference.

| Package Height | Max 320mm, customizable |

| Diameter | Ø 25-Ø134mm, customizable |

| Material | Glass, metal, and plastic |

| Shape | Round, Oval, Square, Flat, curved, Cup-Shaped, etc |

If your product specifications are not listed, please contact our packaging machine experts for consultation. Contact Now

What kind of label material is used on the TY-P150 shrink sleeve labeling machine?

| Label Material | PVC, PET, OPS etc |

| Label Material Thickness | 0.03-0.05mm |

| Label Length | 40-200mm, customizable |

| Label Folding Diameter | Max 200mm, Customizable |

| Paper Roll Inner Diameter | 3″-10″ which is adjustable |

join the success

Looking to make your package visually stunning and instantly capture consumer attention on the shelf?

Discover how Tengyi shrink sleeve labels provide 360-degree full coverage and allow for high-quality printed designs that make your product stand out. Contact our packaging specialists today to explore customized shrink sleeve solutions designed to enhance your brand image!

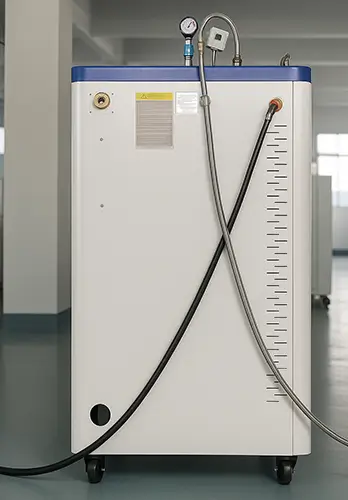

Two Main Kinds Heat Tunnels for Shrink Sleeve Machine

Tengyi shrink sleeve machine is compatible with both hot air shrink ovens and steam shrink ovens.

The two greatly differ in the principles of heating, performance, range of application, and the composition of the costs.

Their flexibility, relatively low startup cost, and suitability for some particular materials make hot air shrink ovens popular.

Steam shrink ovens, however, are best suited for products with intricate container shapes along with those that need high-end appearance, since these ensure uniform and gentle heating.

💨 Steam Shrink Tunnels

Heating Method: Uses hot steam as the heat transfer medium, surrounding the package in the tunel.

Heat Transfer & Performance:

Steam is around 20 times more efficient than hot air when it comes to heat transfer. It provides smooth, even heat at lower temperatures—usually between 77°C and 93°C—which is gentler on materials.

Shrink Quality:

Excellent for full-body labels, especially on odd-shaped containers like bottles and jars. The finish is often smoother and more uniform than with hot air.

Best For:

Ideal for high-end packaging, food, and pharma products. Performs especially well on PET and glass containers, and works with shrink films like PVC, PETG, OPS, and PLA.

Energy Consumption: 20–30kw, higher than that of a hot air shrink tunnel

🔥 Hot Air Shrink Tunnels

How It Works:

These systems use forced hot air to apply heat, often with a recirculation feature to boost efficiency. They can run on either electricity or gas.

Heat Transfer & Performance:

Since air doesn’t transfer heat as efficiently as other methods, these tunnels typically run at higher temperatures—usually between 93°C and 232°C, with some reaching up to 260°C.

Shrink Quality:

For standard applications, these work well. However, complex shapes can be a challenge, and if the settings aren’t just right, you might see imperfections like wrinkles, fisheyes, or burn marks. For example, PET film can turn white if the temperature isn’t suitable.

Best For:

Great for items with medium shrink temperature needs and those that shouldn’t get wet. Ideal for flat or slightly curved surfaces. Works well with films like PET and PVC.

Energy Consumption: 15-18kw, lower than steam heated shrink tunel

Pro Tip: Choose Steam for high-end beverages and complex bottle curves.

Choose Hot Air for budget-friendly lines and simple cylindrical containers

Industries Using Tengyi Shrink Sleeve Labeling Machines

TY-P150 Shrink sleeve labeling machine delivers a high-quality appearance with labels that adhere smoothly and without wrinkles, making it particularly suitable for the packaging of high-end products

| Industry & Examples of Products | Key Needs |

|---|---|

| Beverage Bottles for Water, soft drinks, juices,etc |

High-speed labeling, tamper-evidence |

| Pharmaceutical Medicine bottles, vials, vitamins |

Regulatory compliance, high qualification rate |

| Cosmetics and Personal Care Bottles of Shampoos, lotions, perfumes, skincare |

Aesthetic appeal, complex shape labeling |

| Household and Chemical Products Cleaning agents, detergents |

Safety information, robust labeling |

| Health and Nutraceutical Health drinks, supplements, vitamins |

Tamper-evidence, branding |

| Consumer Goods Pens, lighters, rolls of tape |

Versatile labeling for rigid items |

Case Study

Cosmetics: 4 Years of Partnership

Premium Packaging for a Top Global Brand

Result: Zero Fish-Eyes & Crystal Clear Presentation. Learn More

Cosmetic: Eliminating the Labor Bottleneck

From Manual Labor to 100 BPM Automated Precision.

Result: 100% Speed Jump & 3 High-Cost Laborers Removed. learn more

If you need an L bar sealer, side sealer

If you’re planning a complete line with a heat tunnel.

Go to our automatic shrink wrap machine page.

It’s the fastest way to see all categories in one place.

And it helps you choose the right system with confidence.