The Overlooked “Profit Killer”—Manual Box Sealing

Packages are accumulating at the packaging line. With three workers, approximately sealing 3-5 boxes every minute. Tapes are prone to breakage, box flaps do not lie flat, and the final seal is uneven and ineffective.

Consequently, companies accept 15-20% unnecessary tape usage, increased shipping damage, and ongoing physical stress on employees. In the long run, these manual problems accumulate, lowering efficiency and increasing the operational costs.

Modern-day logistics requires case sealers. Regardless of whether one is operating on a simple taping machine or full automated solutions, transitioning to an auto box taping equipment is capable of generating 2-5 times more consistent output with reduced downtime and a safer working environment.

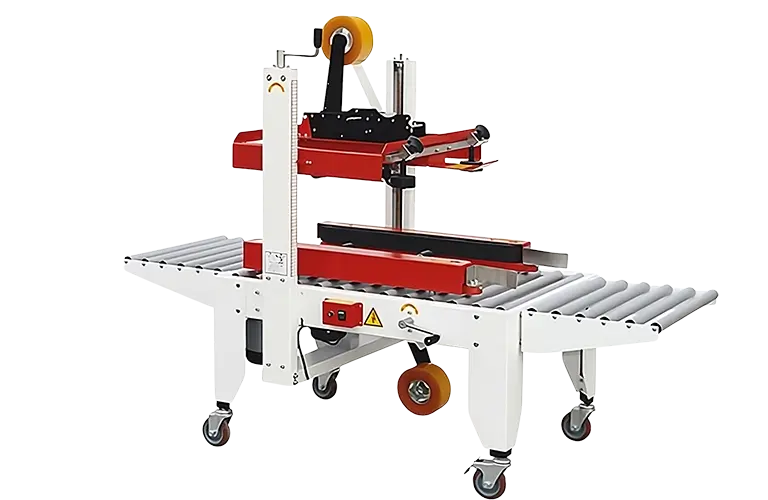

What is an Auto Box Taping Machine? (Definition and Common Misconceptions)

An auto box taping machine is more than a tape applicator. It is a uniform system combining folding of flaps, top and bottom sealing with simultaneous, automated box infeed/ outfeed. It has core elements such as the tape head, drive belts, and sensors to have a uniform tension of the tape across the box seam at a rate of 8-25 boxes per minute.

Common myth:

A lot of people think it is applicable only to taping. In practice, more expensive models will be programmed to fold top and bottom flaps automatically, avoiding tape lift-off due to substandard manual folding.

These systems are compatible with pressure-sensitive tape (PST) and water-activated tape (WAT), which pierce cardboard fibers to provide a high degree of tamper evidence.

Classification Breakdown: box taping machine Classification Guide

1. Semi-Auto vs Automatic box taper:

Semi-Auto: manual box feeding + folding flaps; the machine only performs the task of taping.

Fully-Auto (Automated taping machine): Photo-eye height adjustment, hands-free operation for variable-height lines

2. Uniform vs Random Box taping machines:

| TYPE | Box Size Range | Speed | Application | Common Pitfalls |

| uniform | Fixed dimensions (e.g., 400x300x300mm) | Semi-auto: 20 cpm (manual flaps);Fully-auto: 8 cpm (auto flaps) | Single SKU runs | E-commerce buys uniform, chokes on small boxes |

| random | ±50% size variation via pneumatic adjustment | 4-6 cpm (cylinder stroke/return limits speed) | Mixed SKU production | Heavy industry downtime from constant adjustment |

E-commerce: Micro-boxes (<150mm any dimension) fail to take uniform case sealers- minimum normally 150x100x100mm.

Heavy industry: Single-SKU runs have adjustment time as a result of using random-size sealers.

Root cause: Lack of fit between the variation of boxes (±10% = Uniform, >±30% = Random) and the capabilities of the machine.

Fix: Check box LxWxH range before buying.

3. Small Box Taping Machines: Minimum 150x100x100mm footprint, 1.5m 2 – good in e-commerce/light use or startup applications. Minor 0.5kW, 500-1,000 cartons/day.

Why Your Line Needs an Upgrade: 4 Key Ways Case Sealers Boost Efficiency

1. Speed Surge: Predictable Throughput

The manual sealing has 3-5 boxes/min with a reduction of 30% after lunch because of fatigue. Case sealers are capable of 8-10 boxes/min, 24/7.

The actual value is predictability: constant cycle time synchronization between upstream filling and downstream palletizing.

Real Industry Example: Food factories reached manual bottlenecks at a rate of approximately 2000 boxes/day.

Automated case sealers deliver 4000-5000 boxes/day (100%+ gain) by eliminating

smoke breaks + shift changes hidden downtime, lifting OEE to 85%+.

2. Waste Elimination + ROI: Tape Savings Model

Manual sealing typically wastes 20-30% tape on overhang (4-6″ tabs vs machine’s precise 2-3″). Case sealers deliver 15% average reduction through consistent application.

Tape Cost & ROI Table (250 workdays/year)

Machine Cost: : $17,000 installed (mid-range uniform case sealer)

Tape Assumptions: 90m rolls @ $0.58/roll;

Manual: 2.0m/box → 45 boxes/roll;

Machine: 1.7m/box → 53 boxes/roll (15% savings).

| Daily Volume | Manual Tape / Yr | Machine Tape / Yr | Annual Savings | Payback Period |

| 1,000 boxes | $3,223 | $2,740 | $484 | > 3 years |

| 2,000 boxes | $6,446 | $5,479 | $967 | 18 months |

| 3,000 boxes | $9,669 | $8,219 | $1,450 | 12 months |

Key Takeaway

>2,000 boxes/day justifies investment on tape savings alone (ignores labor/time gains).

1,000-1,500 boxes/day: Need labor savings to justify

3. Safety First: RSI Prevention

Manual sealing: Stooping per day = lifting 500-1100 lbs/shift-3 times lumbar overload increasing insurance payments every year.

Case sealers: Strain reduced 70% Slashing injuries 50-80% and insurance expenses 10-20% Case sealers Stand-straight push/tilt tables cut back strain 70% and injury rate 50-80%.

Market safety: Light curtains + e-stops | Instant, OSHA-compliant protection.

4. Brand Consistency: The Unboxing Moment

Manual taping: All workers apply tape differently: slanting, uneven experience of unboxing.

Case sealers: Always perfectly centered tape, which is a professional, consistent brand image.

Water-activated tape: shreds fiber on opening, tamper-evident security, customers’ trust.

Varying box sizes? Auto-adjusting tape heads deal with distorted boxes, no edge lift or rework.

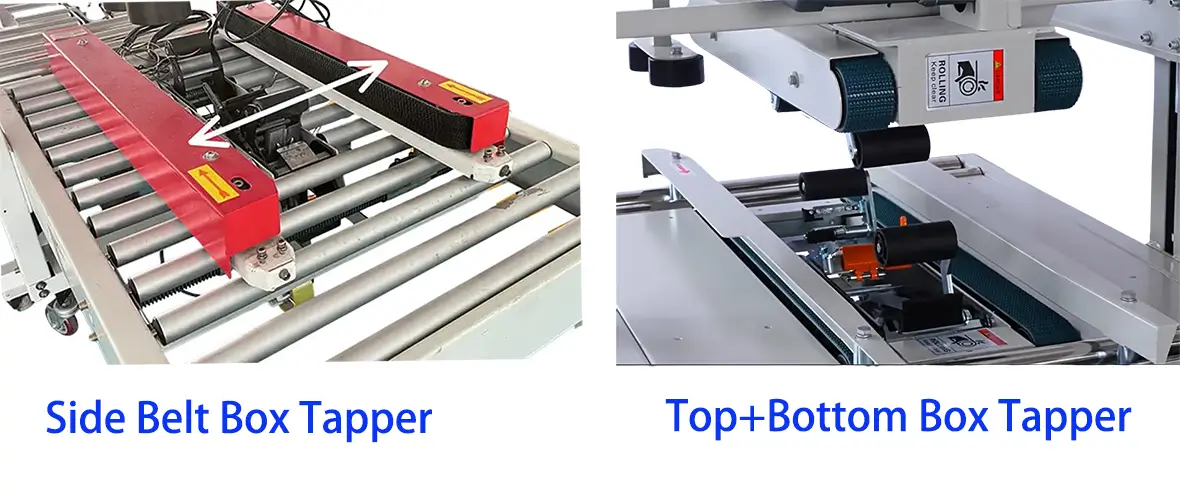

Selection in Practice: Side Belt vs Top+Bottom Drive: Factory Reality Check?

Drive systems define reliability- bad selection will easily increase downtime. Assess factories: box weight, fluctuation of size, flatness of the base.

| Model | Factory Max Box Weight | Application | Factory Pain Points |

| Side Belts | 20-35kg | Light-medium, stable-size boxes | Heavy boxes ≥30kg slip easily; upgrade to textured belts required |

| Top+Bottom | 30-50kg | Heavy, tall boxes, unstable fills | 20% pricier, but highest OEE, logistics MTBF >5000hrs |

| Bottom Only | 25-40kg (rare) | Dedicated bottom sealing/heavy boxes | Fails on light boxes; Normally seen on case erectors |

Factory Selection Guidelines

<20kg light boxes: Side Belts—best value, roller base protects contents

>25kg heavy boxes or H>500mm: Top+Bottom—mandatory, dual grip prevents tilting/bulging

Significant tests: Box base flatness, case size variation, fill stability not weight.

Risks: Wrong Side Belts on heavy boxes = doubled downtime; Keep rough-surface belts (>0.8mm texture) in spare parts inventory

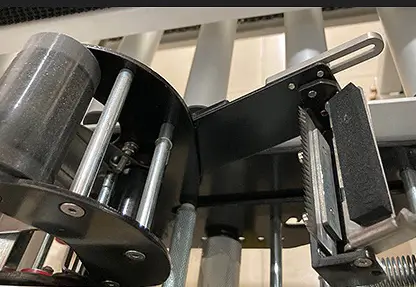

Maintenance & Pitfalls: How to Extend Uptime and Service Life

Maintaining a case sealer in good condition requires regular maintenance. Problems that crop up are normally due to normal wear or wrong adjustments and not a huge mechanical failure.

Dirty tape paths: Clean rollers and empty tape line every few days to allow even tape feeds.

Wrong tension: Since the settings of the tension depend on the model of the tape used, follow the advice given by the manufacturer to prevent loose seals or the tape snapping back.

Dull cutting blades: Replace cutting blades when they become dull rather than allowing them to become dull and cause a rough cut and unplanned stoppage.

Keeping up with all these minor maintenance activities is useful in maintaining a constant operation and preventing any downtime to minimal levels.

Manual to Automated: The Scaling Path

Taping machines deliver serious returns by cutting labor costs, speeding up case sealing, and giving every box a clean, professional finish. As we move into 2026, choosing the right drive system and understanding the real ROI can unlock higher throughput without slowing growth.

Your packaging line should support expansion, not hold it back. Unsure whether a side-drive or top-and-bottom sealer is the better fit?

Schedule a free sample box test or explore our automatic case sealers to find an option that matches your needs and budget.

Author: Shing Xu, Package machine consultant.