Contents

The shrink film is typical in packaging as a way of wrapping products for their storage and transportation. The thing many companies fail to understand is that the type of shrink film they invest in directly influences a machine’s performance and long-term maintenance.

You might have invested a lot in industrial shrink-packaging equipment. Nevertheless, most business executives will realize later that the improper film will silently raise maintenance costs, increase downtime, and wear out equipment faster.

It can save your investment and ensure that your equipment is as long-lasting as possible, and this is a thing many individuals ignore. This is not just a guide to the basics but an illustration of how to actually match POF, PVC and PE films to your equipment to achieve long term stability and the best possible ROI.

Learning about Film Types: The Right Film to Use with Your Equipment

It is important to get to know the clarity of various materials in machines, speeds, and types of products before deciding on a particular shrink film. Every piece has some unique benefits which are based on the needs of your operation.

POF (Polyolefin): The Modern Standard for High-Speed Operations

Think of POF as the premium option that’s become the industry standard for good reason. It is a multi-layered co-extruded film (usually 3 or 5 layers) that is strong, crystal-clear, and has an amazing gloss. POF is a food-safe, FDA-approved material and is the preferred material to use in food, pharmaceutical, cosmetic, and retail packaging.

Think of POF as the premium option that’s become the industry standard for good reason. It is a multi-layered co-extruded film (usually 3 or 5 layers) that is strong, crystal-clear, and has an amazing gloss. POF is a food-safe, FDA-approved material and is the preferred material to use in food, pharmaceutical, cosmetic, and retail packaging.The most interesting thing about POF is its versatility. It is lightweight, easy to wrap around strangely shaped objects and resistant to puncture. It does not emit toxic fumes and bad odors when heated, as PVC does, which is safer for your staff and your clients.

High Efficiency and Precision Shrinkage

POF works with various packaging equipment, including automatic L-Bar sealers and side sealers. The key to getting perfect results is precise heat control and uniform airflow distribution. This eliminates common issues like wrinkles or “dog ears” on your packages. If air entrapment is a concern with your products, pre-perforated POF film lets gases escape, giving you that clean, tight-fitting finish every time.

High-Performance Cross-Linked Film: Built for Speed and Strength

If you’re running automated high-speed lines or packaging heavy-duty items, Cross-Linked POF film is worth a closer look. Think of it as POF’s tougher, faster cousin, explicitly engineered for demanding production environments.

The difference is:

- Superior Performance You Can Feel: These films are powerful, with high tear and stretch resistance, so your packages stay protected even in rough conditions. The seals are more durable, and with shrinkage rates reaching up to 80%, you achieve that tight, professional wrap that looks great and protects better. Compare that to standard POF at 50-60% shrinkage, and you can see why cross-linked film creates such a secure package.

- Maximum Efficiency That Impacts Your Bottom Line:

Want to unlock insane speed on your packaging line?

The cross-linked and high-performance films are specifically designed for that purpose.

They match perfectly with high-speed machines like horizontal flow wrappers.

We’re talking over 250 packages per minute!

Only top-quality film—with way better stretch and strength—lets those fast machines hit their full power.

Imagine jumping from 150 packs per minute to 250+. That’s nearly 70% more output.

Maximum efficiency that hits your bottom line hard—in a good way. And dramatically improves your ROI.

Sustainability and Safety Advantages

POF is leading the packaging industry’s shift toward a circular economy.

- Environmental Safety: POF has no chlorine-based compounds or plasticisers. It does not emit any toxic substances or other damaging fumes when heating or sealing, which makes it an accepted substitute to PVC.

- Recycling Innovation: POF is fully recyclable. The cross-linked and general-purpose POF products containing Post-Consumer Recycled (PCR) material (up to 30%), certified under GRS 4.0 (Global Recycled Standard). These options help you meet sustainability goals while reducing virgin material usage.

With high transparency, superior strength, puncture resistance, and FDA/EU food contact compliance, POF has become the ideal choice across food and beverage, pharmaceuticals, consumer goods, and industrial packaging sectors.

PVC (Polyvinyl Chloride): Understanding the Real Cost of “Cheap” Film

PVC once dominated shrink packaging because of its low cost and excellent shrinkage performance. But that traditional advantage now comes with serious operational, engineering, and compliance challenges that many businesses don’t fully understand.

Challenge One: The Hidden Operational Costs

PVC might appear to be less expensive initially, but when it is put into production and transportation, the faults start manifesting themselves. What seems to be a low initial cost may end up causing additional problems, time, and unseen expenses along the way.

| Operational Issue | What It Means for You |

| Becomes Brittle in Cold | Poor cold resistance means the film hardens and cracks during winter transport or cold storage, compromising product protection. |

| Attracts Dust | Due to its polarity and plasticizer characteristics, PVC easily collects dust during packaging and storage, leaving packages looking hazy or unclear. |

| Sharp Seals | Heat-sealed edges are hard and sharp, creating injury risks for operators and potentially scratching products. |

| Sticking and Carbon Buildup | Tends to stick to sealing bars during heat sealing and leaves carbon deposits on equipment, increasing daily maintenance hassles and costs. |

Challenge Two: The Engineering Risk Nobody Talks About—Equipment Corrosion

The secret expense of PVC: It includes chlorine, which generates severe issues of engineering in hot working conditions, and poses direct threats to your machine resources.

Critical Risk Mechanism: Hydrogen Chloride (HCl) Gas Release

When your sealing knife and shrink tunnel reach typical operating temperatures (around 150–200°C), PVC’s thermal stability breaks down. Actually, it can begin to decompose even below 120 C, liberating hydrogen chloride (HCl) gas.

The Impact of this on Your Equipment:

Corrosion Mechanism: When there is humidity, the HCl gas produces acidic substances, which are very corrosive to metals such as copper and carbon steel in your equipment.

Equipment Damage: This type of corrosion results in pitting and rusting in important locations- heat sealing bars, tunnel chambers, and other parts. It significantly accelerates mechanical damage, especially with poor ventilation or elevated temperatures in the sealing zone.

Challenge Three: International Markets Compliance Risks.

With the world becoming increasingly environmentally conscious and supply chains becoming greener, PVC is being rapidly eliminated by the market through recycling challenges and fears of chemical leakages:

When dealing with chemicals, some rigid restrictions and regulations must be followed:

Use of PVC has long been criticized by environmental and regulatory bodies, who state that the material can leach dangerous chemicals like dioxins and phthalates during manufacture, use, and disposal.

- REACH Regulation In Force: The EU REACH restriction has also been implemented and prohibits weighted lead concentrations in PVC products of 0.1 or above.

- International Prohibitions: PVC packaging has been banned or limited in many countries, including Canada, Spain, South Korea, and the Czech Republic.

The Bottom Line on PVC

The most recent materials in the shrink film sector, e.g., PETG (polyethylene terephthalate glycol) and POF (polyolefin), are non-toxic and FDA-compliant, and do not discharge toxic gases during heating. Their equipment is less expensive to maintain, is less sensitive to cold, and easier to use.

It not only makes sense but also demands upgrading to materials that support green and sustainable development strategies to protect your production efficiency, reduce equipment corrosion and maintenance costs, and ensure long-term adherence in foreign markets.

Click the image below to see how PE film compares with PVC film on our YouTube channel.

PE (Polyethylene) Shrink Film: The Workhose Industrial Film

- The fundamental PE strengths

| Characteristic | What It Delivers | Best Applications |

| Strength and Durability | PE is excellent in terms of resilience, tear resistance, and puncture resistance, which is why it is suitable for heavy-duty and multipack applications. The LDPE film offers outstanding elasticity and strike strength. | Heavy industrial, construction products, pipe, and massive logistics packaging. In the case of multipacks (beverages, water bottles), a 0.03 mm PE shrink film layer guarantees safe bundling. |

| Environmental and Safety | Excellent chemical stability, non-toxic, and unscented. Food-grade PE (as well as HDPE) is certified by the FDA to be used asa food contact material. PE is also quite recyclable and aligns with sustainability objectives. | Companies in high-safety hygiene sectors – food, pharmaceuticals, electronics. Increasing the need for PE films that have greater recycled material and material that can be recycled. |

| Protective Qualities | LDPE is waterproof, moisture-resistant, and dustproof, while also offering good electrical insulation properties. | Construction E-commerce packages, construction materials, outdoor storage covers, and moisture covers. |

- Technical Specifications That Matter

| Performance Metric | Industry Standards | What This Means for You |

| Thickness Range | PE film lies typically between 0.01mm and 0.2mm, with flexible PE film extending to 250m. For large, heavy, and constructional products, thicker films (0.05mm to 0.1mm) are usually applied to increase tear resistance. Increased thickness gives tensile strength and tear resistance required in heavy-duty packaging. | Higher thickness provides the tensile strength and tear resistance needed for heavy-duty packaging. |

| Clarity and Gloss | High-quality PE shrink film can have a light transmittance of up to 90%. In the case of modern resin blends, like Metallocene Linear Low-Density Polyethylene (MLLDPE), transparency, toughness, gloss and smoothness are greatly improved, and the historical issues of thicker films with clarity are defeated. | Modern PE film isn’t just for low-visibility applications anymore, especially products modified with LDPE and high-clarity LLDPE. |

| Shrink Performance | Quality PE shrink film requires 50% longitudinal shrinkage and 40% transverse shrinkage to ensure a tight fit. PE shrink film from LLDPE raw material can achieve longitudinal elongation exceeding 300%. | High shrinkage rates guarantee tight, seamless packages. PE shrink film generally requires longitudinal shrinkage ≥30%. |

| Shrink Mechanism | Another point to keep in mind is that the PE shrink film cold shrink force (strength when cooled) is by far higher than its hot shrink force (strength when heated). | That tightening force generated when the film cools to make the final tight package requires enough cooling space at the exit of your machine. |

- Machine Compatibility and Processing Requirements

For heavy-duty applications and sustainability requirements, equipment such as the TENGYI Sleeve Wrapper is specifically engineered to handle high-performance PE shrink film. This ensures compatibility across a spectrum of materials—from standard LDPE to the latest high-strength multilayer co-extruded PE film and single-material PE structures compliant with 100% recycling standards. You get robust durability aligned with future environmental requirements.

| Processing Stage | Key Requirement | Why It Matters |

| Cutting and Sealing | Cutting thicker PE film requires a Hot Knife system. Thin Ni-Chrome wires aren’t recommended. | Thin Ni-Chrome wires have definite limitations with heavy-duty and high-performance PE films and have been superseded by more reliable mechanical cutting/Hot Knife systems. |

| Extrusion Process | Single- or multi-layer PE film production is usually done using a blown-film extrusion or co-extrusion system. High-quality films must have a rotating die head and a high-precision thickness control system. | The co-extrusion technology is primarily used to produce high-performance PE film (high-barrier properties or high transparency) and to layer materials such as LDPE, HDPE, LLDPE, or mLLDPE to achieve the desired performance. |

Engineering Specifications: Cutting Systems and Long-Term Maintenance

High heat sealing and cutting are essential in high-output packaging lines that are stable. You have to match the sealing system with the thickness of your film, melting temperature, and thermal properties.

The blade design is important when you are driving at high speeds. The form of the knife influences cleanliness of your seals and wear and tear of your machine in the long-run.

Here’s an easy look at blade materials, custom blade shapes, and how to handle residue from different types of film.

Blade Material and Core Technology Differentiation

For all three main shrink films, we recommend high-quality tool steel heat seal knives with Teflon coating to ensure smooth, clean film separation after cutting with no residue.

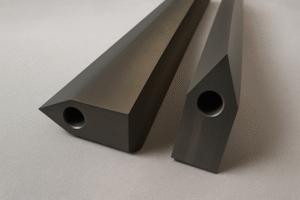

The real difference lies in the unique blade tip shapes engineered for specific equipment and film thicknesses:

Precise Aesthetics for Retail Lightweight Film: POF/PVC (Sharp Blade Tip)

- Application: POF and PVC are generally applied in the packaging of lightweight retail, personal care products, and the food industry, where aesthetics and clarity following shrinkage are very important.

- Cutting Requirement: These thin-gauge films have a design of sharpening and focusing blade tips.

- Value: This design produces a very good, clean seal line, giving a better appearance of packages after shrinking in terms of aesthetics and ultimate shelf appeal.

Constant Stability with heavy industrial film: PE (Wide, Stable W-Shaped Blade Tip)

- Usage: PE film will find use in heavy-duty bundling and industrial multi-pack it will be used where the priorities are on strength and long-term stability.

- Cutting Challenge: PE film is heavy and has a high heat absorption (thermal absorption), which makes the heat dissipate quickly. Old-style fine seal/cut lines are unable to provide enough heat immediately to allow consistent fusion sealing, and frequent interruptions to production are observed due to broken or cold seals.

- Our Solution: We use a broader, stronger W-shaped blade tip, which results in: Large instant heating capacity, which prevails over PE film heat dissipation issues. An engineered, trusted seal is finished along with a cut, which goes a long way in adding stability and integrity of the seal in heavy-duty PE packaging lines.

The Secret to Operating with Continuity: Professional Maintenance and Material Deposit Management

No matter what film you are using, it is very important to keep blades constantly clean to ensure the quality of seals, the life of equipment, and the ultimate ROI. Differences in Deposits: Various films produce various amounts of residues:

- PVC: Thermal degradation can easily leave carbon residues (carbon buildup) on seal/cut blades

- POF: Can leave minor film residues

- PE: It normally leaves sticky deposits

Your Benefit: Our packaging machines are made so that they are easy to clean and maintain in a cost efficient manner. Professional maintenance every few days stops such residues, which make a poor seal, contaminate the film or wear the blade faster, which makes the best seals in the long term.

Flexible Customization Service: Satisfying Demanding Packaging Needs

In case your production line has to support lightweight retail film (concentrating on beauty) and heavy-duty PE bundling film (focusing on strength), we provide flexible and custom blade designs and quick changeover options. To ensure that your shrink packaging machine will perform equally well and reliably in sealing over applications, we have structured our engineering team so that it will customize the most appropriate seal/cut blade geometry to your application requirements.

B2B Manager’s Investment Logic: Think “Cost Per Package,” Not “Cost Per Roll”

Smart management considers film procurement as an investment, looking at its long-term effects on the longevity of the equipment as well as its efficiency.

Attention on Total Cost of Ownership (TCO) and Downgauging Strategy.

- Calculation Metric: Pay attention to Cost per package and not the original price per roll.

- Downgauging Strategy: There are lots of facilities which now use 19-micron PVC. A smarter approach? Move to 15-micron, high-strength POF, thinner. Yes, POF is more expensive per kilogram, yet it is tougher in nature and thus, you can get more length in a roll- you can fit more products. Besides, you can save time cleaning the residue of PVC and changing the corroded parts, which reduces the cost of packaging.

Longevity and Risk Management of Assets.

The right equipment is vital in matching the asset lifespan: POF-based machinery, as a rule, can last up to 10 years. In case your machine has open carbon steel and lacks the relevant design or ventilation care, the intense as well as long-term use of PVC will cause high intensity of rust and pitting in critical parts in a short time.

Prudent Risk Management Strategy:

- Short-Term PVC Use: If you must use PVC, control risk within acceptable parameters:

- Control heat seal and shrink tunnel temperatures to avoid overheating

- In high-temperature zones (heat seal bar, tunnel interior), use anti-corrosion coatings like stainless steel, aluminum alloy, or Teflon

- Ensure effective fume extraction and ventilation

- Medium-to-Long-Term Planning: For machine longevity, operational safety, and export compliance, gradually transitioning to chlorine-free films like POF is the more prudent strategy.

Quick Comparison: Film Performance at a Glance

| Attribute | PVC (Polyvinyl Chloride) | PE (Polyethylene) | POF (Polyolefin) |

| Material Type | Polyvinyl Chloride | Polyethylene | Polyolefin |

| Cost | Similar cost, dependent on specifications and procurement volume | Similar cost, dependent on specifications and procurement volume | Similar cost, dependent on specifications and procurement volume |

| Clarity | High. Recycled PVC may appear yellow; fresh material may appear blue. | Most PE films have lower transparency than PVC and POF. | High / Excellent |

| Typical Thickness Range | 15–50 microns (1.5–5 mil) | 40–100 microns (4–10 mil) | 15–30 microns (1.5–3 mil) |

| Environment/Safety | Releases HCl gas at high temperatures, posing localized corrosion risk. | Non-toxic, recyclable. | FDA Approved, Non-toxic, recyclable. |

Film First, Machine Second: The Right Procurement Process

Your shrink packaging investment decision should center on the film to ensure long-term, high-efficiency equipment operation.

Final Decision Principle: Eliminate Procurement Risk

A critical mistake we see all the time: businesses purchase machinery first, then expect it to work perfectly with their existing film stock. That’s backwards.

The correct procurement process:

- Define Objectives: Determine your core packaging goals (high clarity, maximum strength, heavy-duty bundling, etc.)

- Material Selection: Select the most appropriate film substrate (POF or PE) based on your objectives and budget

- Equipment Configuration: Only then procure Shrink Wrap machinery manufactured or configured specifically for that film’s characteristics (thickness, heat-shrink mechanism, etc.)

Expert Validation Service: Free Testing, Video Delivery

End the speculation and unwarranted exposure. The packaging line should not begin with trial and error. We also provide Specialist Accreditation Services to get rid of your selection issues:

How It Works:

- Send Samples -Send product and film samples to our engineering center.

- Free Testing – We will carry out a rigorous, free real-life test, which will run your materials on our special equipment.

- Video Delivery– Be provided with a full video of the testing process so that you can check the results of packaging yourself, as well as, machine compatibility.

- Get Tailor-Made Solution – We will give an entire package of solution, such as the choice of the film, and the respective packaging machine setup.

This is done to ensure that your selected film performs at its best and that the packaging quality is more stable and professional.

Eliminate the risk and do it properly. Contact us and take your free validation test now.

Author: Mr. Shing Xu, Packaging Machine Consultant. All data verified by Mr. Lei Xiong, Shrink Wrap machinery expert with over 5 years of experience in the shrink wrap machine industry