| Power Supply/Power |

|

Three-phase 380V 50/60Hz 3kw |

| Sealing System |

Heating Source |

Uses stainless steel heating tubes, long service life |

|

Sealing Blade |

Uses anti-stick high-temperature resistant alloy sealing blade, blade exterior coated with Teflon non-stick film |

|

Sealing Blade Temperature Control |

Uses Huibang digital temperature controller, temperature adjustable from 0-300°C |

|

Sealing Blade Dimensions |

Width and height are manually adjustable with handwheel, horizontal sealing blade length L500 mm |

|

Maximum Sealing and Cutting Dimensions |

L unlimited * (width + height) ≤400mm, height ≤100mm, base lifting |

|

Vertical Sealing Cylinder |

Airtac |

|

Sealing and Cutting System |

Controlled by 850W Huxin servo for horizontal sealing, firm and stable sealing, low noise during sealing |

| Conveyor System |

Belt |

PU textured, thickness 1.3mm |

|

Motor |

Chuanming motor, ensures smooth conveying |

|

Detection |

Uses Japanese Omron photoelectric sensors, accurately and sensitively detects product conveying and stopping |

| Recycling System |

Motor |

Chuanming motor, ensures accurate and uniform speed for recycling waste |

|

Induction Switch |

Uses Omron to accurately control the recycling waste time |

| Film Feeding System |

Motor |

Chuanming, ensures smooth film-feeding |

|

Induction Switch |

Uses Omron to accurately control the film feeding length |

| PLC |

|

Inovance |

| Intermediate Relay |

|

Schneider |

| Contactor |

|

Schneider |

| Touch Screen |

|

Kunlun Tongtai 7-inch color screen |

| Applicable Materials |

|

POF |

| Packaging Speed |

|

20-50 packs/minute (determined by the actual product) |

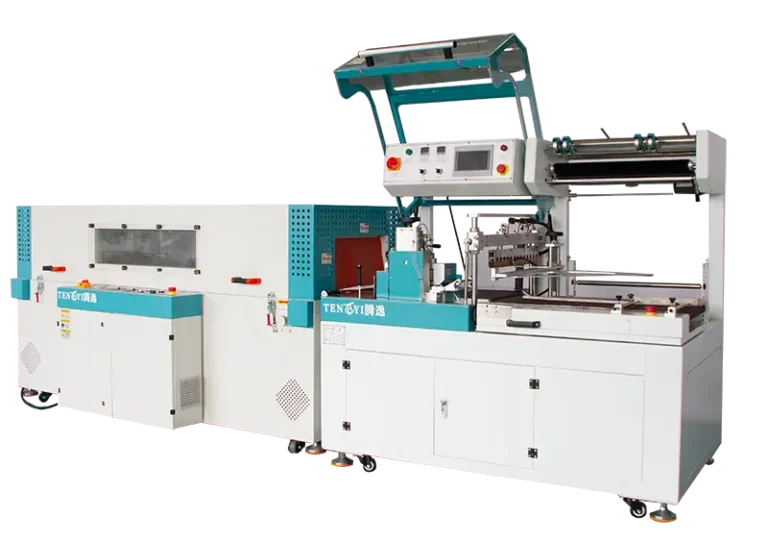

| Mechanical Dimensions |

|

L1750W1080H1450mm |

| Included Accessories |

|

One piece sealing blade, two pcs synchronous belts |