Abstract: Elevate Performance – Realize Strategic Development

The case study shows that a manufacturer of high-end retail electronics that makes screen protectors overcame slow and inconsistent shrink wrapping by implementing Tengyi TY-L450 Fully Automatic L-Bar Sealer, a tool that creates high-speed packaging with precision.

I. The Client’s Challenge: Balancing Output, Cost, and Brand Aesthetics (Trust & Pain Points)

1. Client Background: A Brand Obsessed with Visual Perfection

This company designs top-quality electronics to serve the premium retail outlets. Packaging here is not merely protection, but also the initial impression that the customer observes.

“We should not let bad sealing lines ruin our well-planned packaging. We must get a solution that will enhance speed without compromising the looks.” –

Client’s Operations Manager

2. The Bottleneck and the Brand Risk of the Old Process

The company was using manual bagging machines that were facilitated by heavy labor before it began working with Tengyi. While the process was serving the purpose, there were two major issues:

- Efficiency bottleneck & high labor costs: More than 20 workers were required on one production line for bagging and boxing. The line was capable of handling just 10,000 units in a day, even with overtime.

- Each box had to be hand-shrink-wrapped and heat-sealed, which reduced production speed, increased costs, and restricted the capacity of the company to take bulk orders.

When the company incorporated the TY-5545 fully automatic L-Bar sealer, it freed 2-3 employees and produced the same quantity in 8 hours.

II. Tengyi’s Professional Solution: (Expertise & Experience)

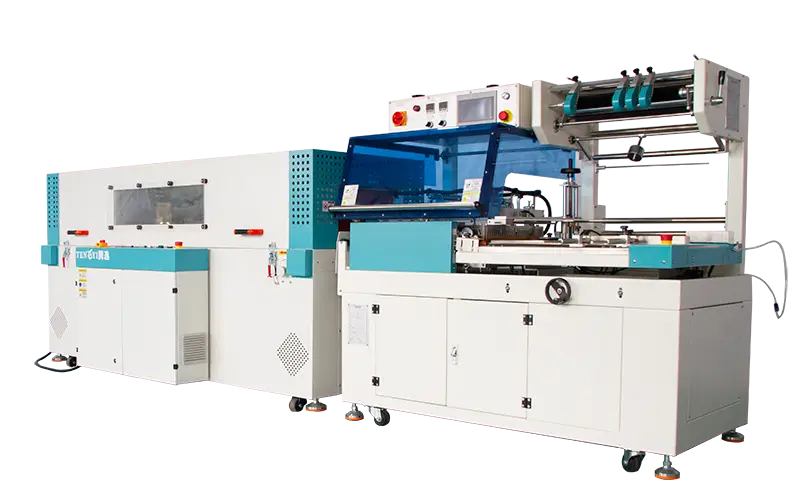

Tengyi suggested the time-tested system after considering the requirements of the client to have stable, clean, and aesthetically steady wrapping:

TY-5545 L-Bar Sealer Fully Automatic + TY-5030 High-Efficiency Shrink Tunnel.

This layout is common in the electronics packaging world and it provides high performance with thin screen protector cases.

1. Core Technical Advantages: Servo Side Sealing & PID Temperature Control

| Technical Feature | Professional Advantage | Client Value |

| Very accurate servo side sealing system. | Panasonic PLC guarantees accurate sealing-knife movement and uniform sealing of shrink film. | Eliminates manual wrapping that is slow and creates clean and high-end retail look. |

III. Excellent Performance: Measured Growth and Brand Premium (Authority and ROI)

After the installation, the line of the client showed measurable improvement.

| KPI | Before (Manual Process) | After (TY-5545L Solution) | ROI Highlights |

| Production throughput | Low and unstable | Stable at 20 boxes per minute | More than 500% efficiency improvement, allowing bigger orders. |

| Labor requirement | 20 bagging/sealing/shrink wrapping workers. | Only 1 operator required | A replacement of 2-3 workers saves labor cost of about ¥250,000 annually. |

Client Testimonial:

“We fixed the longstanding packaging appearance problem, and stability and speed of the machine assures that we can handle bigger orders. Our package image was so much better with this system!”

IV. Conclusion: Turning Packaging Into Brand Equity

Your brand image should not have to face the consequences of poor packaging. This case study shows that selecting the appropriate automation solution can be used to strike a balance between efficiency and aesthetics precisely.

The Tengyi TY-L450 / TY-5545 L-Bar Sealer serves the market very well, particularly the manufacturers who are conscious of brand and productivity.

We provide automation that makes your position stronger in the market. By partnering with Tengyi, you can ensure uniformity in quality, eliminate long-term labor stress and create a stronger visual impact on the packaged products delivered to consumers around the globe today.

Want to upgrade your shrink wrap speed? Scan the WhatsApp QR code to talk with our expert now.