The use of a case sealer in your packaging line is not all about automation. It is about making the process smoother, faster and more reliable to enhance your bottom line.

A case sealer may help increase production speed, ensure consistent sealing quality, and reduce operating expenses when properly integrated.

A single properly configured automatic case sealer can save up to 40 percent of manual labor in taping and increase productivity by over 25 percent in most factories.

Imagine this: rather than wasting hours with workers manually sealing cartons, boxes move freely through a conveyor, are folded, closed, and ready to ship to the recipient in a matter of seconds.

That is a productivity dream for any hectic production floor.

Pre-Integration Checklist

Before fitting your case sealer, ensure it fits perfectly into your current production flow. Here is a step-by-step checklist:

1. Upstream Equipment (Before the Case Sealer)

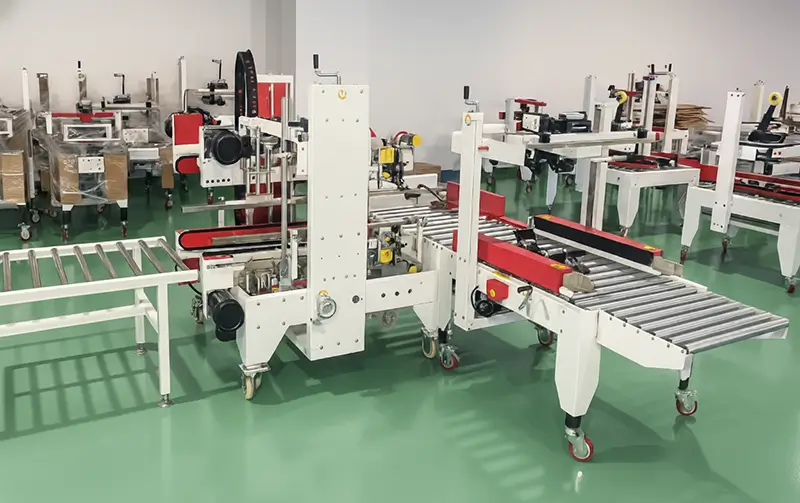

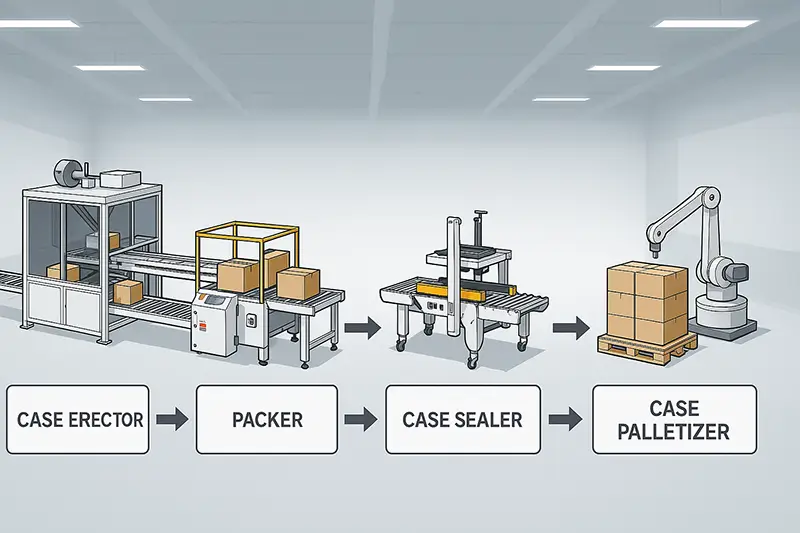

A case sealer usually operates after several other machines, including:

- Case erector or carton former: assembles and folds empty boxes

- Case packer or manual packing station: packs your products in cartons

- Checkweigher: verifies weight and integrity of product

- Labeling machine: attaches labels to the carton side or top flaps

These parts feed cartons into the semi-automatic case sealer or automatic case sealer.

Ensure that the conveyors, product height and speeds are aligned on all the linked machines to avoid misaligned flaps or jamming.

2. Downstream Equipment (After the Case Sealer)

When cartons are sealed, they are taken to the next level where they are labeled, strapped or palletized.

- Case printer or labeler: the barcode or shipping information is printed

- Carton strapping machine: straps are used to provide extra stability

- Case palletizer or robotic arm: piles cartons on pallets

- Pallet wrapping machine: wraps the load before transportation

When these elements are combined, they form a complete automated system that shapes, fills, seals, and prepares products for distribution.

3. Conveyor Setup and Line Design

The design of your conveyors should be made properly so that your case sealer can integrate well.

- Adjust conveyor height and width to match the infeed and outfeed of your sealer.

- Verify that carton sizes and tape specifications are compatible with the tape head.

- Provide enough floor area for operators and maintenance.

- Add safety features, such as guards and emergency stops around moving belts.

These little details ensure that there is a steady production flow that is safe at all times.

Step-by-Step Integration Process

Are you ready to have your case sealer running at full capacity? Follow this roadmap for a smooth integration:

1. Position and Install the Case Sealer

Place the semi-automatic case sealer or automatic case sealer between the packing and labeling area.

Adjust height to conveyor levels, fix the unit in place and connect the required power or air supply, in case pneumatic operation is needed.

2. Connect the Conveyors

Synchronization is essential in integration.

Cartons should be fed into the infeed belt of your case sealer by your upstream conveyor, and the downstream conveyor must be run at the same pace as the labeler or palletizer.

Pro Tip: Photoelectric sensors or automatic carton detectors will ensure that there is enough spacing and no jams.

3. Align the Carton Feed Direction

Cartons must be fed straight and at equal spacing.

In case of a random automatic case sealer, ensure that its sensors identify and adapt to the sizes of cartons to ensure uniform sealing.

4. Test With Sample Cartons

Test the system using sample cartons before full operation. Check for:

- Even tape application

- Correct flap folding

- Wrinkle-free clean seals

- No crushed and non-aligned boxes.

Each case sealer is calibrated and tested at Tengyi so that when it is shipped, it is ready to use.

5. Integrate With Control Systems

In higher-level production, you can connect the PLC of your automatic case sealer to the main network.

This enables simultaneous start and stop, real-time error reporting and tracking production data: all essentials of a smart factory today.

Maintenance Tips for Smooth Operation

Even the most trusted case sealer requires regular care to maintain its performance. Downtime can be very expensive, and it can be avoided with a few minutes of maintenance.

- Clean the tape head daily. Remove the adhesive stains that may interfere with the quality of cutting. Replace blades every 1-2 years.

- Lubricate side belts weekly. Enhances smooth movement and reduces premature wear.

- Inspect drive belts monthly. Repair or replace worn or slipping parts before they cause failures.

Regular check-ups will help to make sure that your semi-automatic case sealer or automatic case sealer will operate effectively during all shifts.

Need Custom Integration Help?

Every production line is unique. That’s why Tengyi Machinery offers customized integration for all case sealer models, whether semi-automatic or fully automatic.

Our engineers collaborate with your team to create layouts that fit your available space, product type, and throughput goals.

If you are designing a new packaging system or upgrading an existing one, contact Tengyi Machinery to plan your next case sealer solution.

Visit Tengyi Case Sealer or watch our operation videos on YouTube to see the machines in action.