If you’ve been running a steam shrink tunnel for a while, you know one thing — even the best systems need a little fine-tuning.

Whether it is shrink sleeve wrinkles or bubbles or steam pressure problems, the majority of problems can be resolved quickly when you know what is actually causing them.

The following is a comprehensive, practical guide, with the insight of a 10-year packaging engineer, full of practical steam shrink tunnel troubleshooting tips that you can use now.

Problem 1 – Labels Wrinkling or Bubbling

Symptoms: Wrinkles, bubbles or irregular shrinkage on sleeves, particularly around bottle necks or curves.

Main Causes:

- Excessive or abnormal steam pressure.

- The steam nozzle position is not in line with bottle surface.

- Inappropriate conveyor speed.

- Label material (like PET) is receiving too much localized heat.

Quick Fix:

- The nozzle position needs to be adjusted so that the steam impacts every side equally.

- Maintain steam generator pressure between 0.2 and 0.4 MPa when using most sleeve materials.

- Depending on product’s nature, a small increase in conveyor speed will reduce exposure to heat.

- Check the quality of film, and store films during their shelf life: PVC (8-9 months) and PET (12 months). Keep in a shaded area.

Pro tip: A 360° steam flow setup (like the TY-W300) ensures uniform heat and eliminates shrink sleeve wrinkles or bubbles completely.

Problem 2 – Steam Pressure Too Low

Symptoms: Sleeves do not shrink completely or are loose

Main Causes:

- Steam generator does not provide constant output.

- Steam line or joint leakage.

- Poor design of condensate drainage steam tunnel in piping that results in condensation build-up.

Quick Fix:

- Examine the steam indicator and safety valve.

- Pipe insulation to reduce heat loss.

- Drain condensate after use to maintain balanced pressure.

If your factory shares one boiler system, make sure your line has a dedicated regulator valve to stabilize pressure at the tunnel inlet.

Problem 3 – Unstable Conveyor Speed

Symptoms: The bottle moves irregularly or jams in the tunnel.

Main Causes:

- The bottom of the product is small, resulting in jamming or toppling.

- Chain belt slip or tension issues.

- Lack of synchronisation with upstream or downstream conveyors.

Quick Fix:

- Recheck roller alignment and tension conveyor.

- Clean the belt frequently to avoid moisture accumulation.

- Adjust your labeler, tunnel, and packing conveyor speed synchronization ratio.

When integrating with a shrink label applicator, keep conveyor center lines aligned for smooth bottle transfer — a key part of shrink tunnel maintenance.

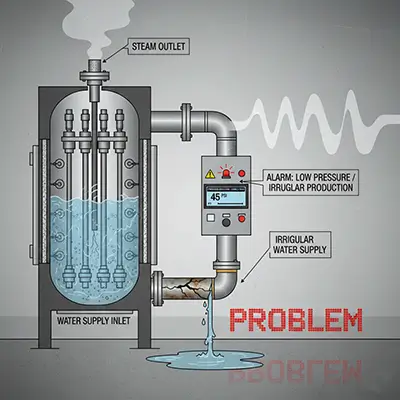

Problem 4 – Steam Generator Water Supply Issues

Symptoms: Irregular steam production, pressure reduction or control panel alarms.

Main Causes:

- Impure water supply (it contains too many minerals).

- Breaking down of the pump or air locking in the line.

- Low water tank level.

Quick Fix:

- Filtered or soft water should be used to minimize the formation of scale.

- Monitor water level sensors every week.

- Evacuate trapped air through the steam pipe system.

Routine shrink tunnel maintenance extends the boiler’s life and keeps steam pressure stable

Problem 5 – Electrical or Sensor Malfunctions

Symptoms: Temperature indications are irregular, tunnel does not warm properly, or there are faults in the control panel.

Main Causes:

- Condensation of sensor contamination.

- Loose wiring connections.

- Faulty PID controller.

Quick Fix:

- Dry and clean sensors weekly.

- Clamp wiring in junction boxes.

- Re-calibrate sensors or controllers that are unstable.

Preventive Maintenance Checklist

Follow these easy tips once a week to keep your tunnel in good condition:

- Drain condensate drainage steam tunnel collector, clean filters.

- Inspect the steam hose to identify leaks.

- Use proper lubrication on conveyor bearings.

- Check steam pressure and temperature meters.

- Clean nozzle head to remove mineral residues.

Plan a complete shrink tunnel maintenance at least once in 3 months – small repairs save huge hours of downtime.

When to Upgrade Your Steam Shrink Tunnel

In case you are having frequent breakdowns, steam pressure problems or poor quality labels, then it is time to upgrade.

In modern tunnels such as the TY-W300 from Tengyi, there are:

- Digital steam flow and temperature regulation.

- Energy-efficient construction, made of stainless steel.

- Integrated condensate drainage steam tunnel system.

- Easy compatibility with the shrink label applicators.

With TY-W300, you will save time, reduce rework, and get great quality of labels, even in high rates of production lines.

Contact Tengyi for Technical Support or Custom Setup

Having some issues and need help with diagnosis?

Our engineers can lead you through live steam Shrink tunnel troubleshooting or design a tunnel configuration to suit your product line.

Contact Tengyi packaging experts today