The choice between a steam heat tunnel and an electric hot air tunnel is another crucial decision that any packaging line using shrink sleeves or films should make.

Both systems involve heat to tighten the film around the products, but in very different ways.

This guide will assist you in choosing the one that best fits your operation when you are concerned with label quality, production efficiency, and long-term control of costs.

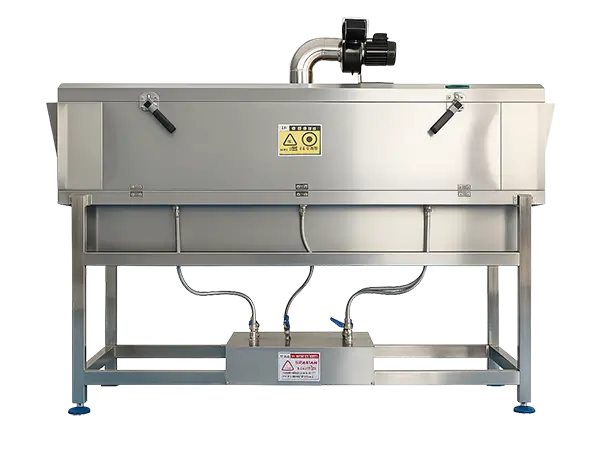

What’s a Steam Shrink Tunnel

A steam shrink tunnel, also known as a steam heating tunnel, utilizes saturated steam as the heat medium. Each product is enclosed by steam which offers 360° uniform heating.

This ensures that the shrink film, particularly PET, PVC, and OPS, fits precisely around the complex shape of the bottles, without wrinkling or bubbles.

Due to their comparatively lower working temperature (90-100 °C), steam tunnels can be used in containers that require heat-sensitive products and in high-end labeling applications.

Models such as TENGYI TY-W300 include adjustable steam nozzles and digital flow control to match different bottle shapes and label thicknesses.

In many cases, a steam tunnel for shrink sleeves provides the best results for premium beverage or cosmetic bottles.

What’s a hot air (Electric) Shrink Tunnel

A hot air tunnel or electric shrink tunnel involves hot air circulation over the film with the help of heating fans and tubes.

The average operating temperature ranges from 130 °C to 180 °C.

It is simpler to install since it requires only an electrical connection( no boiler or water supply) and offers flexible setup for smaller or moisture-sensitive products.

Many manufacturers also utilize a heat tunnel for shrink sleeves when handling dry products or small production runs.

Steam Heat Tunnel vs Hot Air Tunnel: Key Differences

Heat Source and Method

Steam

Provides moist, uniform heat for premium shrink performance, suitable for high-speed shrink rates of 80–120 pieces per minute when paired with a sleeve shrink labeling machine.

Electric

Dry, focused heat for simpler, lower-volume packaging compared to steam heat tunnels, widely used with automatic L-bar sealers, side sealers, and sleeve bundlers.

Steam shrink tunnels are generally preferred over hot air tunnels when the appearance of labels is crucial.

Steam spreads heat uniformly, resulting in smooth, wrinkle-free, and bubble-free labels, even on irregular or contoured containers.

That is why manufacturers of beverages, cosmetics, and pharmaceuticals use the steam systems to produce shrink sleeves.

An electric tunneling process can produce a good result on basic, straight-sided bottles but may perform more slowly with thick film or PET materials, where more controlled heat transfer is required.

In terms of throughput, steam heating tunnels such as the TY-W300 can reach 100-150 bottles per minute.

whereas some smaller models, such as TY-5030 or TY-4525, can run 60-100 bottles per minute, depending on configuration.

The steam systems are more stable in terms of performance and appearance when used in continuous and high-speed production.

Energy Consumption and Operating Costs

The cost of energy varies with the extent of production and the use of utilities.

| Feature | Hot Air Tunnels | Steam Tunnels |

|---|---|---|

| Power Consumption | About 15–18 kW/h | Approx. 27–30 kW/h (including steam generation) |

| Operating Temperature | 130–180 °C | 90–100 °C |

| Best Suited For | Small to medium batches | Continuous, high-volume shrink wrapping |

| Infrastructure Needs | No water or steam infrastructure required | Requires steam generation setup |

| Heat Transfer Efficiency | Moderate | More efficient with fewer rejected labels |

Due to the need to supply continuous heating to steam heat generators, their power consumption is also more than that of hot air tunnels.

Additionally, some heat shrink tunnels feature systems for heat recovery and reuse, distinguishing them as more energy-efficient than older heating designs.

Maintenance and Equipment Longevity

Hot air heat tunnels:

Less mechanical components and no boiler system. However, frequent cleaning of heating tubes and air fans is necessary to prevent dust buildup, which can cause uneven heat distribution and color changes in the film.

Steam shrink tunnels (e.g., TY-W300):

These tunnels are made of 304 stainless steel and equipped with sealed steam systems.

Needs daily condensate draining and occasional nozzle maintenance, but generally has a longer service life and improved resistance to corrosion.

In continuous production facilities, steam-heating tunnels tend to offer increased reliability and longer service life.

Both systems are considered durable heat tunnels for industrial use, but steam types perform better under long-term, high-speed demands.

Recommendation:

Select a steam shrink tunnel when your product requires high-quality, wrinkle-free labeling on complex bottle shapes.

Select an electric hot air tunnel when dealing with moisture-reactive or low-volume products that require only a plug-and-play setup.

Application Scenarios: Which One Fits Your Business

| Criteria | Steam Shrink Tunnel | Electric Shrink Tunnel |

|---|---|---|

| Bottle Shape | Irregular, curved | Simple, straight |

| Label Type | PET, PVC, OPS sleeves | PET, POF, PE, PVC films |

| Speed Range | High-speed, continuous (100–150 bpm) | Medium-speed, small batch (≤100 bpm) |

| Energy Source | Steam / boiler | Direct electricity |

| Best for Industries | Beverage, cosmetics, pharmaceuticals | Small-scale packaging, dry food, electrical materials |

| Operating Temperature | 90–100°C | 130–180°C |

Recommendation:

Select a steam shrink tunnel when your product requires high-quality, wrinkle-free labeling on complex bottle shapes.

Select an electric hot air tunnel when dealing with moisture-reactive or low-volume products that require only a plug-and-play setup.

Which One Is Better for Shrink Sleeves on Bottles?

In contemporary bottle labelling, steam heat tunnels are the most popular for good reasons:

- Excellent Finish Label: Bubbles-free and perfect finish on oddly shaped bottles.

- Consistent High-Speed Performance: 150 bpm with uniform shrink performance.

- Ideal for Heat-Sensitive Products: Works at lower temperatures, avoiding damage to products.

- Premium Presentation: Increases shelf presence of beverages, cosmetics and health products.

Models such as TENGYI TY-W300 steam tunnel for shrink sleeves combine Digital temperature display, adjustable nozzles, and internal or external steam generators to offer unrivaled flexibility and durability in rigorous manufacturing environments.

Experience the TY-W300 Steam Shrink Tunnel

Ready to see how TENGYI’s TY-W300 steam heat tunnel performs in real production?

The TY-W300, with a 1.3-meter heating zone, adjustable steam baffles, and 304 stainless-steel construction, provides superior sleeve shrinkage at lower temperatures, ideal in PET and luxury bottle packaging.

Key Takeaway

For small-scale or dry product packaging, go with an electric hot air tunnel.

For premium labeling, high-speed production, and intricate package designs, choose steam heat tunnel.

Explore our full range of heat tunnels to compare models and find the right fit.

Visit our heat shrink tunnel page for details.