What’s Horizontal Flow Wrapper with Shrink Tunnel?

Our Horizontal Flow Wrapper(120/150/180) with Shrink Tunnel is a versatile shrink wrap packaging solution designed for POF shrink film applications. Unlike standard food flow wrappers that mainly use OPP film for candies, cookies, or bakery items, this model combines the speed of horizontal flow wrapping with the tight finish of heat shrink wrapping.

After sealing, products pass through a heat tunnel, creating a smooth, clear, and secure shrink finish. This makes it an excellent choice for multipacks, industrial products, bottled beverages, cosmetics, and non-food items.

Key Features

Using a major brand PLC and a three-servo control system, stable sealing and cutting are ensured.

The system is designed for industrial production and large-scale(30-120packs/minute) manufacturing applications

As a shrink wrap machine, this horizontal flow wrapper must be paired with a heat shrink tunnel.

This machine utilizes POF shrink films to ensure high-quality shrink wrapping. When compared with L bar sealers such as the TY-5545 series which have waste film widths of 6-7 cm, this machine saves 20-25% of film.

Ideal for packaging single products or small multipacks (2-3 items together)

How does it work?

A horizontal flow wrapper with heat shrink tunnels provides high-efficiency horizontal pillow packaging. It’s technology cores include the continuous shrink film bag forming process, product wrapping, and heat-shrink heating.

In industries such as food, pharmaceuticals, and everyday chemicals, horizontal flow wrappers and heat shrink tunnels are widely used to shrink wrap small items.

Product Conveying

Products are loaded onto the stainless steel 304 conveyor belt and driven by a chain mechanism. Every product occupies a separate compartment on the conveyor by using dividers and fixed intervals. Product arrangements are kept orderly and horizontally oriented at a predetermined speed.

Step 1

Film bag forming and Product wrapping

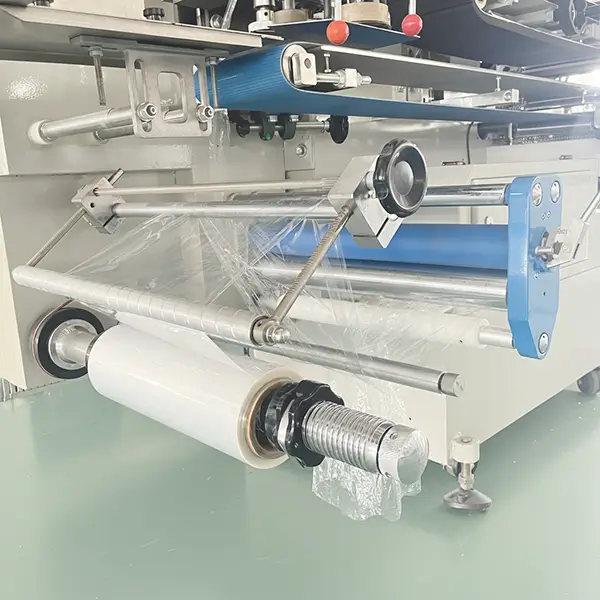

The machine employs a film bag former to continuously transform flat POF shrink wrap film into bags.

As each product enters, the film bag wraps around it, creating an initial package in a seamless, continuous process.

Step 2

Sealing and Cutting

Step 3

Key Machine Components

Our horizontal flow wrapper’s chain-driven 304 stainless steel conveyor, with evenly spaced dividers, ensures perfect product alignment and efficient transport.

Film Bag Former: Transforms POF shrink film into pillow-shaped bags for professional packaging.

Four independent temperature controls on the horizontal heat blades (up and down) as well as the vertical heat wheels assure precise temperature setting.

MCGS Display: Provides real-time status and easy-to-read diagnostic information.

User-Friendly Interface: with clear labels for Start, Stop, and Jog buttons simplifies operation.

Ensures safe and reliable machine operation with built-in safety features like emergency stops and sensors.

Film Roll Holder: Securely supports POF shrink film rolls for consistent and reliable film feeding.

Horizontal Flow Wrappers vs. Automatic L-Bar Sealers

| Feature | Horizontal Flow Wrappers | Automatic L-Bar Sealers (TY5545 Series) |

|---|---|---|

| Shrink Wrap Speed | 60-120 packages/minute, ideal for industries pursuing ultra-high shrink wrap speed | Around 30-60 packages/minute, suitable for industries requiring moderate speed |

| Compatible Product Size | Limited by conveyor width and pre-set bag size; generally smaller than L-bar sealers 80mm ≤ L ≤ 300mm / 35mm ≤ W + H ≤ 240mm / 50mm ≤ H ≤ 100mm |

Generally bigger than horizontal flow wrappers; e.g., vertical L-bar sealers allow a max height pass-through of 15cm height |

| Use Cases | Single specification, long-term production, large batch sizes; products under 10 cm height (e.g. cup noodles) | Higher tolerance, adaptable to wider and larger product specifications |

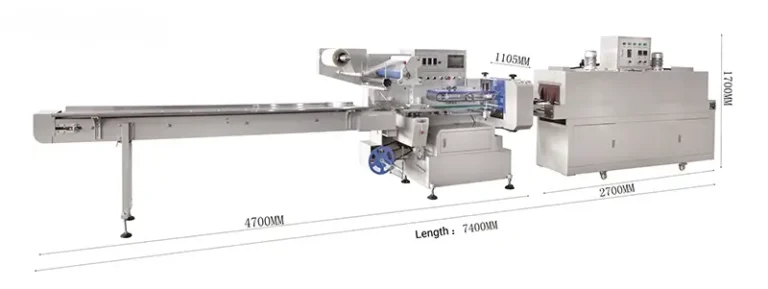

| Space Requirements | Large footprint needed (~7 meters) due to horizontal flow wrapper plus heat tunnel | Smaller space needed (~4 meters) for L-bar sealer plus heat tunnel |

| Cost | More expensive, approximately $9,815 to $11,217 USD including heat tunnel | Relatively affordable, around $5,609 to $7,011 USD including heat tunnel |

| Machine Adjustment Difficulty | More complex, involving conveyor belt and bag forming devices; usually requires factory engineers for setup and tuning before shipment | Relatively easier to adjust L-bar sealer settings and physical setup |

Widely Applicable Across Multiple Industries

Why Partner with Tengyi for Industrial-Grade Horizontal Flow Wrappers & Heat Tunnels

Experienced Experts, Proven Solutions

Our core technical team has over 20 years of automated equipment manufacturing experience. As experts in shrink packaging, we combine deep industry knowledge with top-tier manufacturing to provide you with the most effective solution.

Industry Insight, Perfect Fit

With over 30 industries served, we understand the needs of diverse industries. In this way, we can precisely identify your pain points and offer a customized, comprehensive equipment solution.

Quality-Assured, Worry-Free Service

Quality and after-sales service are our top priorities. From delivery to long-term maintenance, we can provide a customized after-sale service plan to ensure your equipment runs smoothly and reliably.

Case Studies

Tengyi Flow Wrapper & Heat Tunnel for Cupped Noddles

Automation: 60-80 pieces/min

Efficiency Leap: Over 6x faster than manual sealing.

"This machine is truly a lifesaver. Three years of running, and it's still rock-solid. We couldn't imagine our packaging line without it."

Mr. Li, Director

Tengyi Flow Wrapper+ Heat Tunnel TY-4525

For Shampoo Bottles (with pump heads)

Handles Complex Shapes with Ease

"This flow wrapper is a huge help. We just place the bottles on, and it handles everything automatically. It's completely effortless and a great stress-reliever."

Ms. Zhang, Operator

- Impressive success story : Horizontal Flow Shrink Wrap Machines in the Cosmetics Industry

To see our full range of shrink wrap equipment, please visit shrink wrap machines page