1. Client Challenge: Balancing Premium Quality with Product Diversity

Client: Bawei Cosmetics (Renowned OEM cosmetic manufacturer)

Partnership Start: 2021 (Ongoing purchases and strategic upgrades)

The greatest difficulty faced by Bawei was striking the balance between accuracy and flexibility. They required very high precision of sleeve labeling machine in their premium products like eye cream. Meanwhile, their multi-brand personal care product line demanded fast line changes and compatibility with multiple sizes, which emphasized the necessity of a flexible cosmetic shrink wrap packaging system that would remain efficient with various products.

| Product Line | Key Challenge | Tengyi’s Solution |

| High-value eye cream bottles | Higher speed and accuracy with requirements of ultra-low defect rates. | Using sleeve labeling machine + TY5030 heat shrink tunnel + PET film, running at 80–100 pcs/min, achieving 99.5% sleeve success rate and 98–99% shrink film yield |

| Diversified personal care products | Adapting quickly to different bottle sizes and shapes | Wide compatibility covering cosmetic bottles under 10cm diameter, 30cm length, and 15cm width, with combined horizontal flow wrapper and shrink tunnel setup |

2. Tengyi’s Professional Solution: Engineering Precision & Flexibility

Tengyi has over 20 years of experience in the automation sector, and its engineers offered a complete, reliable packaging system to Bawei, which was accurate, precise, and flexible.

a) High-Precision Sleeve Labeling Machines (4 units): Ensuring Premium Quality

Expertise: For eye cream bottles, Tengyi used a custom sleeve labeling machine such as TY-P150 with a vision positioning system to ensure that the sealing line on the shrink film does not cover the product logos. It runs at 80-100 pcs/min and can changeover quickly to different products with varying diameters using different film guides.

Maintenance: It requires minimum maintenance, just the heat-sealing blade changes after six months of operation.

Value to Procurement: The machine provides a cutting length variation within 0.5mm and is capable of 99.5% product qualification with a huge amount of reduction in PET film waste, enhancing overall cost-effectiveness.

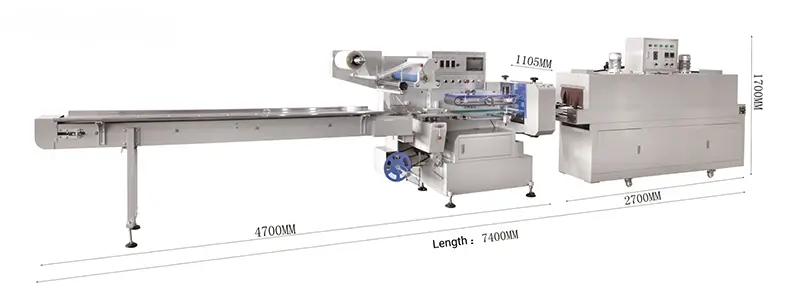

b) Horizontal Flow Wrapper (2 units): Enabling Rapid Market Response

Technical Advantage: The modular structure and the simplified HMI interface permit continuous and stable production above 100 pcs/min.

Management Value: Line adjustments and changeovers take only 10-20 minutes, with film size, machine height, and sealing stroke, reducing downtimes and enhancing flexibility to handle the fast-changing market requirements.

c) Large-Scale Line Integration (20+ Automatic Case Sealers): Proving Reliable System Integration

Bawei has already bought more than 20 automatic case sealers in 2021. They clearly show their long-term confidence in the reliability of the Tengyi system, its easy integration and compatibility with fully integrated production lines.

3. Outstanding Results & Long-Term Value

The sustainability of business value of automation solutions of Tengyi is further confirmed by the fact that Bawei has continued to buy its products for four years.

| Performance Metric | Key Results & Business Impact |

| Productivity | Sleeve labeling speed up to 100 pcs/min, failure rates remain low, and stable market supply is guaranteed. Cost savings in labor per year: around USD112549.00 |

| ROI | Four successive procurement cycles assure equipment reliability, low TCO (Total Cost of Ownership) and an outstanding cost-performance ratio. |

Tengyi’s Continued Support

Tengyi is still assisting Bawei to overcome challenging, complex packaging issues through high efficiency, high precision, and highly stable automation systems (such as sleeve labeling machines, horizontal flow wrappers, heat shrink tunnels, and automatic case sealers).

The comprehensive operational statistics and overtime engineering practice show that Tengyi is a reliable partner when companies want to upgrade automated cosmetic shrink wrap packaging lines.

When your company needs a more efficient and dependable industy shrink wrap machine to automate the packaging production process, contact us and get a customized solution developed.